Description

In the demanding world of industrial automation, where digital inputs from field sensors must deliver unerring accuracy to prevent misreads that trigger false alarms or overlooked hazards, engineers often contend with wiring clutter, signal degradation, and integration hurdles in safety-critical setups. The Triconex 9566-810 tackles these challenges as a specialized termination panel for digital inputs, streamlining the connection of multiple discrete signals while preserving the integrity needed for reliable process control. Consider a scenario in a refinery’s safety instrumented system (SIS), where proximity switches, limit detectors, or pressure switches feed status data back to the controller—if noise or poor termination corrupts even one signal, it could cascade into an unwarranted shutdown or undetected fault, inflating costs and risking compliance. This panel proves essential in such high-reliability environments, offering a centralized hub that simplifies field wiring without compromising the TMR architecture’s fault tolerance.

The Triconex 9566-810 shines in applications requiring dense I/O handling, like burner management or emergency shutdown loops, where modular integration allows quick scaling without rewiring entire cabinets. By incorporating current-limiting resistors and commoned terminals, it shields against overcurrent and ground faults, aligning with goals of system stability and I/O signal precision. In broader terms, it’s a linchpin for industrial automation strategies focused on minimizing human error during commissioning and enhancing diagnostics for predictive upkeep. Terms like “process control,” “high reliability,” and “I/O signal” naturally apply, as the Triconex 9566-810 empowers teams to maintain seamless data flow from the plant floor to the control room, supporting SIL 3-rated operations where every connection counts toward uninterrupted uptime.

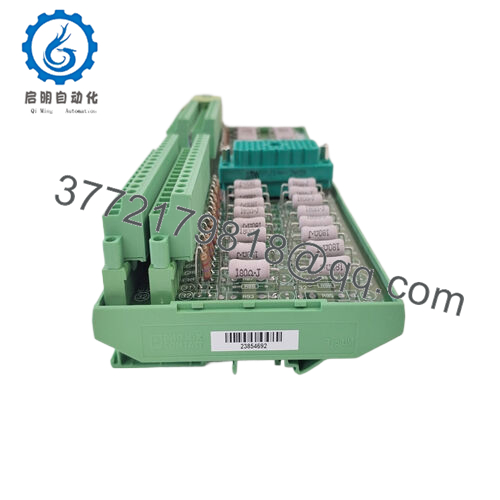

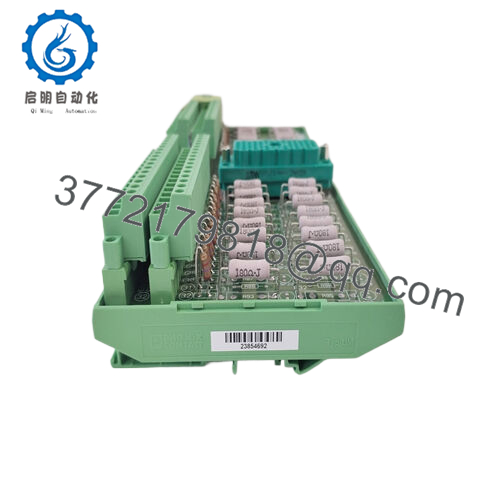

Positioned at the interface between Triconex digital input modules and field devices, the Triconex 9566-810 functions as a passive termination panel that routes 32 discrete signals into a compact, organized layout, eliminating the need for point-to-point cabling that plagues legacy systems. It connects via a standard ribbon cable to modules like the 3504E or 3604E, slotting into the Tricon v9–v10 chassis alongside power distribution and communication backplanes to form a cohesive I/O subsystem. In this setup, incoming signals from dry contacts or voltage sources—typically 24 VDC—are conditioned through per-point 180-ohm resistors, ensuring consistent voltage levels reach the controller without attenuation or spikes, while common PWR+ and PWR– terminals distribute power efficiently across all channels.

This design supports the TMR stack by mirroring connections across redundant modules, allowing the system to vote on input validity in real time and bypass faulty paths automatically. Diagnostics flow upstream too: any open circuit or short is detectable via the host module’s status monitoring, often integrated with protocols like Modbus for remote polling. Unlike bulkier alternatives, the Triconex 9566-810 reduces enclosure footprint by consolidating terminations, making it ideal for distributed control where space and accessibility matter. For example, in a multi-chassis configuration, it pairs with expansion modules to handle high-density inputs from vibrating machinery, maintaining signal isolation to prevent EMI-induced errors. This thoughtful positioning in the automation architecture not only accelerates deployment but also facilitates hot-swaps during live operations, keeping the focus on core control logic rather than peripheral wiring woes.

- 9566 – 810

| Specification | Details |

|---|---|

| Model Number | 9566-810 |

| Brand | Triconex (Schneider Electric) |

| Type | 32-Point Digital Input Termination Panel |

| Input Voltage | 24 VDC (24/48 VDC compatible) |

| Operating Temp Range | -40 to +70°C |

| Mounting Style | DIN rail or panel mount |

| Dimensions | 8.5″ x 5″ x 1.5″ (approx. 216mm x 127mm x 38mm) |

| Weight | 1.1 kg |

| Interface/Bus | 50-pin ribbon cable to Triconex DI modules |

| Compliance | SIL 3, IEC 61508, CE, ATEX |

| Supported Protocols | Modbus RTU (via host module) |

| Typical Power Draw | <1W (passive) |

Selecting the Triconex 9566-810 equips your system with a foundation for enduring signal fidelity, where its resistor-protected inputs prevent transient damage that might otherwise erode performance over cycles of thermal stress or electrical surges. In daily operations, this means sensors reporting valve positions or flow switches deliver data with less than 1 ms variability, enabling tighter loop control and fewer process deviations—crafted to withstand the grind of 24/7 duty, it bolsters long-term performance by cutting the frequency of field interventions that disrupt workflows.

Integration ease further amplifies its value, as the commoned design trims wiring runs by up to 50% in dense panels, freeing engineering time for algorithm tuning rather than cable management. Maintenance becomes less burdensome too: blown conditions are rare thanks to inherent limiting, but when they occur, isolated terminals allow spot checks without de-energizing the rack, streamlining compliance audits and reducing overhead in regulated sectors. For teams chasing 99.999% availability, the Triconex 9566-810 delivers that edge by embedding resilience into the I/O layer, turning what could be a vulnerability into a scalable asset that adapts to evolving plant demands without mandatory redesigns.

Across petrochemical refineries, the Triconex 9566-810 terminates inputs from flame detectors and level switches in furnace controls, enduring corrosive vapors and seismic activity while ensuring high reliability for process control in explosive zones. Its 32-point density supports fast data cycles, capturing state changes that safeguard against overheat events and maintain critical system uptime.

In power utilities, it handles discrete signals from circuit breakers and turbine interlocks, positioned in control rooms to interface with SCADA for grid stability monitoring under extreme thermal swings. This setup excels in environments demanding unwavering I/O signal accuracy, preventing blackouts through vigilant input aggregation.

Nuclear facilities also leverage the Triconex 9566-810 for radiation monitor terminations, where its SIL 3 pedigree and commoned architecture facilitate redundant voting in radiation protection systems, upholding safety amid high-radiation and vibration challenges for flawless operational continuity.

Triconex 3504E – 64-point high-density digital input module that connects directly for expanded channel handling in TMR configurations. Triconex 3604E – Enhanced 32-point DI module alternative with integrated fault detection for superior diagnostics.

Triconex 9563-810 – 16-point termination panel for lower-density 24V applications, ideal for space-constrained legacy upgrades.

Triconex 9565-810 – 48VDC variant for commoned inputs, suited to higher-voltage field devices in power sectors.

Triconex 9771-210 – Analog input termination add-on to balance hybrid I/O setups with digital panels.

Triconex 9662-810 – Output termination counterpart for full bidirectional signal routing in control loops.

Triconex 9566-710 – 24VDC non-intrinsically safe version for standard industrial environments.

Triconex 9750-210 – Relay output panel for complementing input terminations in actuator-driven sequences.

Prior to deploying the Triconex 9566-810, cross-reference your digital input module—such as the 3504E—against the Triconex compatibility matrix to confirm ribbon cable alignment, and assess enclosure IP rating for the site’s dust or moisture levels to avoid condensation on terminals. Ensure DIN rail provisions include at least 2 inches of clearance for heat dissipation, and verify power source stability at 24 VDC with ripple under 500 mV to prevent false triggering. Firmware on the host chassis should be v9 or v10; update if needed using Schneider’s TriStation tools before final connections.

Ongoing care for the Triconex 9566-810 centers on visual and electrical verifications—monthly scans of terminals for looseness via torque checks at 0.6 Nm, particularly in vibration-heavy areas, to sustain contact reliability. Use a continuity tester quarterly on sample points to affirm resistor integrity, logging any deviations exceeding 5 ohms for proactive swaps. Annually, during SIL proof tests, simulate input faults across channels to validate system response, but limit to non-disruptive dry runs; clean dust from connectors with compressed air, steering clear of abrasives. This measured protocol, rooted in IEC 61508 practices, preserves the panel’s role without overcommitting maintenance cycles.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626