Description

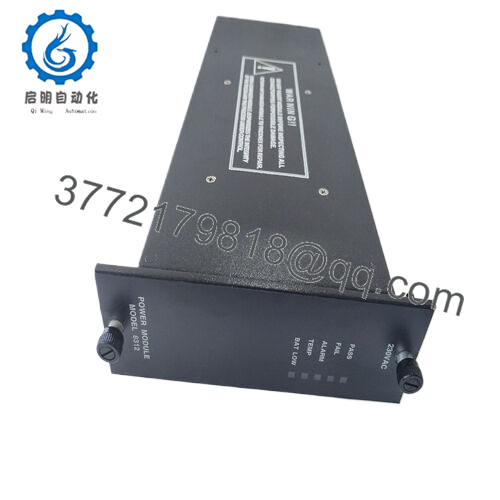

Product Model: 8312

Product Brand: Triconex

Product Series: Triconex Safety Instrumented System (SIS)

Product Features:

- Triple Modular Redundancy (TMR) for maximum fault tolerance

- Central processing unit for Triconex safety controllers

- Designed for continuous, safety-critical operation

- Proven performance in oil & gas, petrochemical, and power plants

Technical Features & Benefits

The Triconex 8312 processor module sits at the core of a Triconex safety system. Unlike conventional PLC CPUs, the 8312 is designed specifically for mission-critical environments where the cost of downtime or unsafe operation is unacceptable. At the heart of its architecture is triple modular redundancy (TMR), which means three independent processors execute the same logic simultaneously. A majority voting mechanism then validates each result, ensuring that a single hardware or transient fault cannot compromise safety.

This TMR concept isn’t theoretical—it’s been proven in thousands of installations worldwide. The 8312 Triconex CPU constantly performs diagnostics on itself and the system, detecting latent errors before they can affect outputs. The benefit is clear: operators gain a higher level of confidence in their automation backbone.

From a performance perspective, the 8312 provides fast scan times and supports complex safety logic without sacrificing stability. It is engineered to integrate seamlessly with Triconex I/O modules, communication cards, and power supplies, meaning users get a system that is modular yet unified.

- 8312

- 8312

Another major feature is hot-swap capability. If a processor module needs replacement, it can be exchanged without bringing the entire system offline, a valuable advantage in industries where shutting down production is a multimillion-dollar decision. Conformal coating and industrial-grade components further extend reliability under harsh conditions such as offshore platforms or desert refineries.

The combination of redundancy, diagnostics, hot-swap design, and rugged construction makes the Triconex 8312 processor card one of the most trusted CPUs for functional safety applications.

Applications & Industry Context

Where do you find the 8312 Triconex module in action? Almost everywhere safety meets complexity. Oil & gas production platforms rely on it to monitor and control emergency shutdown (ESD) systems. A single false trip can cost operators millions, but a missed shutdown command could be catastrophic. The 8312 balances both sides, ensuring shutdowns occur only when truly required and that all signals are transmitted reliably to field devices.

In petrochemical complexes, the module coordinates safety interlocks that protect reactors, distillation towers, and flare systems. Even when hundreds of analog and digital signals are flowing through, the 8312 maintains deterministic performance, critical for avoiding unsafe process conditions.

Power generation plants—whether nuclear, coal, or gas turbine—also turn to the Triconex 8312 processor for turbine protection, boiler management, and balance-of-plant safety. Its continuous monitoring ensures that overspeed, overpressure, or loss of cooling scenarios trigger appropriate protective responses.

Field engineers often share anecdotes of how the 8312 has prevented accidents. One offshore operator recalls how the module’s diagnostics identified a processor lane fault during routine operation. Instead of a trip, the redundant design allowed continued production while maintenance replaced the faulty section, avoiding both a shutdown and a potential hazard.

This real-world reliability explains why the 8312 CPU is specified in new safety projects globally, from LNG export terminals in Qatar to chemical plants in the United States.

Installation & Maintenance Insights

Deploying the Triconex 8312 processor module doesn’t require complex procedures, but following best practices ensures long-term reliability. The unit slots into the Triconex main chassis and connects directly with power supplies, I/O modules, and communication cards. Proper grounding and secure seating of connectors are essential, as vibration in industrial environments can sometimes loosen poorly installed cards.

Engineers value the hot-swap capability: should a CPU lane show diagnostics indicating degradation, the module can be replaced while the system continues running in redundant mode. This significantly reduces mean time to repair.

For ongoing maintenance, the processor performs continuous self-checks, but periodic firmware updates are recommended to keep pace with evolving safety standards. Many facilities schedule system proof-tests that include functional verification of the 8312 Triconex CPU to ensure the module still responds within required safety timeframes.

Environmental considerations should not be overlooked. The processor is coated for protection, but cabinet conditions should remain within specified humidity and temperature limits. Adequate airflow inside panels helps avoid heat buildup, extending the life of both the 8312 and surrounding electronics. With disciplined installation and preventive maintenance, operators regularly achieve decades of service from these modules.

Technical Specifications Table

| Specification | Detail |

|---|---|

| Product Model | 8312 |

| Brand | Triconex |

| Series | Safety Instrumented System (SIS) |

| Function | Main Processor Module |

| Processor Architecture | Triple Modular Redundancy (TMR) |

| Diagnostics | Continuous self-test, fault detection |

| Hot-swap Capability | Yes |

| System Compatibility | All Triconex safety controllers |

| Typical Applications | ESD, BMS, turbine protection, SIS |

| Environmental Protection | Conformal coated electronics |

| Reliability Rating | High availability, fault-tolerant |

| Lifecycle Support | Long-term vendor and third-party support |

Related Models

- 8110 Triconex Processor Module – earlier generation processor for smaller SIS systems

- 8311 Triconex CPU Module – alternate version with different diagnostic features

- 8355 Triconex Communication Module – links the system to DCS or SCADA networks

- 3700A Triconex I/O Module – digital input/output for safety logic execution

- 3511 Triconex Power Supply Module – delivers regulated power to processor racks

- 3008 Triconex Main Chassis – housing for CPUs, I/O, and communication cards

- 4409 Triconex Termination Panel – field wiring interface for signals to/from CPU

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626