Description

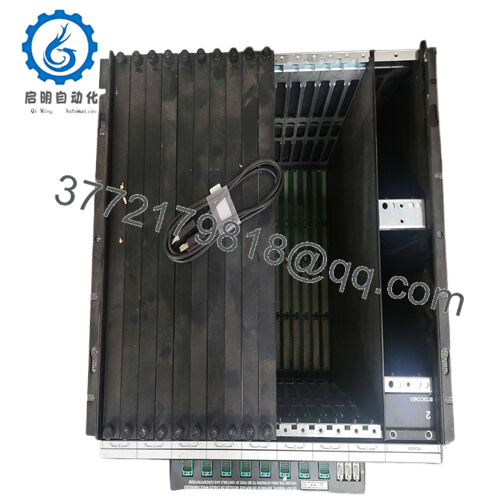

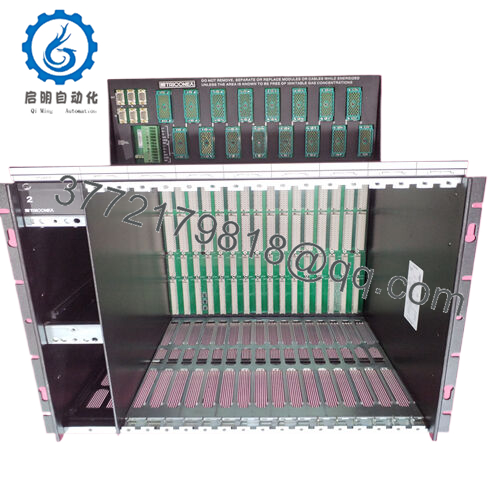

The Triconex 8111 is a key element in the Triconex automation ecosystem. As a high-speed communication gateway, it facilitates seamless data exchange between various field devices and central control systems. By seamlessly integrating with the Triconex backplane architecture, this module enables efficient communication throughout the entire automation stack, enabling real-time monitoring and precise control of industrial operations.

8111

Main features and advantages:

It supports multiple industry standard protocols, including Ethernet/IP, Profinet, and Modbus TCP, enabling seamless integration with a large number of existing and new field devices. This versatility makes it highly adaptable to different industrial settings and simplifies the process of upgrading or expanding automation systems.

The Triconex 8111 also has high-speed data processing capabilities, capable of processing large amounts of data in real-time. This is particularly important in applications that require quick decision-making, such as high-speed production lines or real-time monitoring systems. In addition, the module is equipped with built-in diagnostic functions that can continuously monitor its operating status, detect potential problems in the early stages, and issue real-time alerts to operators. This enables proactive maintenance and reduces the risk of unexpected system failures.

It supports multiple communication protocols and high-speed data transmission, ensuring seamless integration with existing systems, reducing engineering costs, and accelerating the implementation speed of automation projects. The real-time data processing capability of this module enables more precise control of industrial processes, improving product quality and production efficiency.

The built-in diagnostic function of Triconex8111 significantly simplifies maintenance work. Engineers do not need to spend hours manually troubleshooting, but can quickly identify and solve problems, thereby reducing maintenance time and costs. This not only improves the efficiency of maintaining the team, but also allows for more efficient use of resources. In addition, the robust design of the module ensures long-term reliability, even in harsh industrial environments with high electrical noise, vibration, and temperature fluctuations.

8111

Technical specifications:

Model 8111

Brand Triconex

Type Communication Gateway Module

Certification CE, RoHS

Supports protocols Profibus and Modbus

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

8111

Application areas:

It is used to manage communication between various components in the production line, such as robotic arms, conveyors, and quality control sensors, ensuring smooth and efficient operation. Its high-speed data processing capability enables real-time monitoring of the production process, allowing for immediate adjustments to ensure product quality.

In the field of aerospace engineering, the Triconex 8111 plays a crucial role in the production of aircraft components. It promotes communication between different systems and ensures accurate and reliable control during the manufacturing process. Its ability to handle complex data and support multiple protocols makes it an ideal choice for the highly specialized and demanding aerospace industry.

8111

Related products:

Triconex 8111- HC – With enhanced data processing capabilities, it is suitable for large industrial projects that require processing large amounts of data.

Triconex 8111-EX – Designed specifically for explosive and hazardous environments, with enhanced safety features and certifications, suitable for chemical plants, refineries, and other high-risk areas.

Triconex 8111- FAST – Provides faster data transfer speeds, making it ideal for applications that require extremely high millisecond response, such as high-frequency trading systems or advanced robotics technology.

Triconex 8111- LOWP – Optimized for low power consumption, reducing the overall energy consumption of the system, promoting energy-saving measures and sustainable industrial operations.

Triconex 8111- COMP – Perfect for installations with limited space, such as control cabinets or onboard automation systems in small industrial settings.

Triconex 8111- RED – Provides enhanced redundancy functionality, further improving system reliability and suitable for critical task applications where any downtime is unacceptable.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626