Description

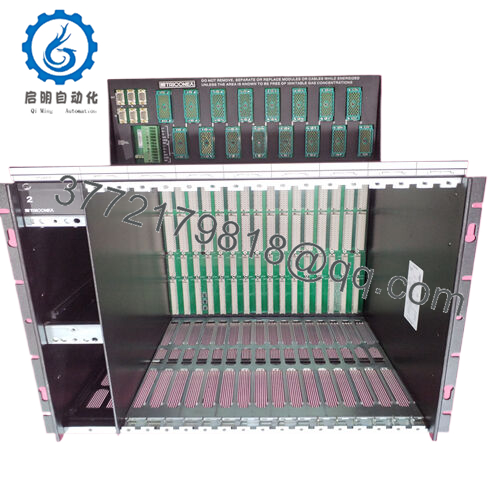

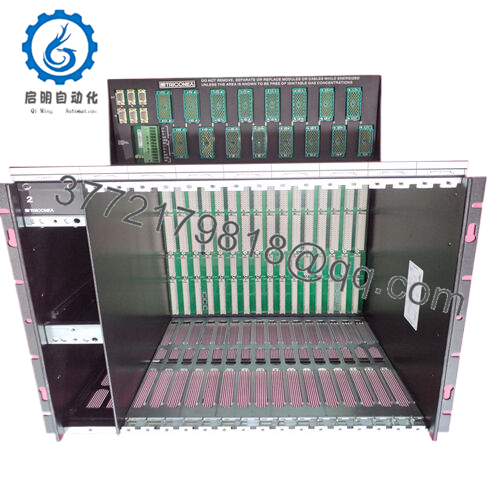

In industrial automation, scaling control systems to handle growing process demands without sacrificing safety or uptime is a persistent challenge. Engineers often wrestle with constrained rack space, intricate wiring, and the need to maintain fault-tolerant operations in high-stakes settings like chemical plants or gas turbines. The Triconex 8111 resolves these issues as an expansion chassis designed to boost I/O capacity within Triconex’s triple modular redundant (TMR) systems, ensuring high reliability for process control. In scenarios where new sensors or actuators must be added—such as monitoring additional pressure points in a pipeline—the Triconex 8111 provides a seamless way to extend the system without disrupting existing operations. Its role is critical in environments where a single fault could lead to costly shutdowns or safety risks, offering a modular solution that maintains system stability and I/O signal integrity.

This chassis is a lifeline for facilities pushing for scalability without the headache of redesigning control architectures. It simplifies the addition of new modules, reducing engineering effort and minimizing errors during commissioning. Terms like “industrial automation,” “process control,” and “high reliability” fit naturally here, as the Triconex 8111 ensures that expanded I/O points integrate smoothly, supporting real-time diagnostics and uninterrupted performance in SIL 3-rated applications, such as emergency shutdowns or burner management systems.

The Triconex 8111 functions as an extension to the Triconex TMR platform, connecting to the main chassis (like the 8100-1) via a high-speed TriBus cable to expand the backplane for up to eight additional I/O modules. Positioned in the automation stack’s I/O layer, it accommodates modules like digital inputs (e.g., 3504E) or analog outputs, processing signals from field devices such as flow sensors or valve controllers. This setup enables the system to handle increased data loads while preserving TMR’s fault tolerance, where three redundant processors vote to ensure accurate outputs, critical for applications like turbine speed control.

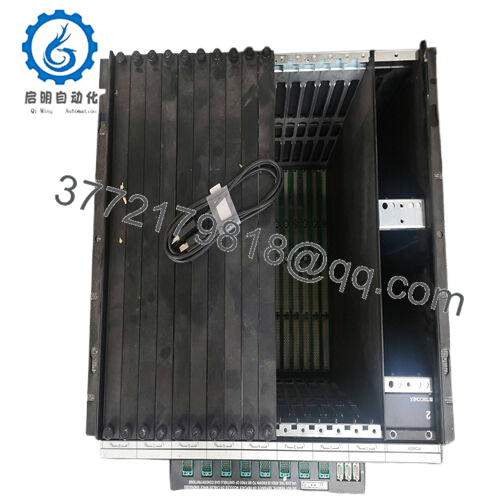

The chassis supports hot-swappable modules, allowing additions or replacements without powering down, which is a game-changer for live process control environments. It uses dual 24 VDC power inputs for redundancy, with built-in diagnostics monitoring power, bus, and module health via LEDs and software alerts. Communication flows through TriBus or Modbus RTU, enabling integration with SCADA for remote oversight. For instance, in a power plant, the Triconex 8111 might house modules managing breaker status inputs, relaying data to the controller for real-time fault detection, all while keeping cabling compact and EMI-resistant. This design reduces installation complexity and enhances scalability, making it a practical choice for expanding control systems without compromising the automation architecture’s integrity.

- 8111

- 8111

| Specification | Details |

|---|---|

| Model Number | 8111 |

| Brand | Triconex (Schneider Electric) |

| Type | Expansion Chassis |

| Input Voltage | 24 VDC (20–32 VDC range) |

| Operating Temp Range | -40 to +70°C |

| Mounting Style | Rack-mounted (19-inch standard) |

| Dimensions | 19″ x 14″ x 8″ (483mm x 356mm x 203mm) |

| Weight | 10.5 kg (without modules) |

| Interface/Bus | TriBus, 50-pin I/O connectors |

| Compliance | SIL 3, IEC 61508, CE, ATEX |

| Supported Protocols | Modbus RTU, TriBus |

| Typical Power Draw | 20W (base, varies with modules) |

Choosing the Triconex 8111 means equipping your facility with a scalable backbone that ensures long-term performance by accommodating new I/O modules without breaking the TMR framework. This translates to fewer operational hiccups—new sensors for gas detection can be added without risking signal errors that might cause false alarms, maintaining process stability even under heavy loads. Its fault-tolerant design delivers 99.999% uptime, critical for SIL 3 environments, reducing downtime costs and extending the lifespan of connected equipment.

The Triconex 8111 also streamlines maintenance by supporting hot-swaps, allowing technicians to address module issues in seconds without halting production. Its standardized slot design cuts commissioning time by simplifying module integration, freeing engineers to focus on optimizing control logic rather than wrestling with hardware. Built-in diagnostics pinpoint faults like power drops or bus errors, reducing troubleshooting time and supporting predictive maintenance strategies. By keeping the I/O layer robust and adaptable, the Triconex 8111 empowers teams to meet evolving regulatory demands and scale operations efficiently, making it a cornerstone for future-proof automation.

The Triconex 8111 is widely used in oil and gas, where it expands I/O capacity for emergency shutdown systems, handling inputs from level switches or outputs to solenoid valves in explosive environments. Its rugged build ensures high reliability under vibrations and chemical exposure, maintaining critical system uptime for process control in harsh conditions.

In power generation, it supports boiler control by housing modules for temperature and pressure inputs, enabling precise monitoring in high-heat settings. The hot-swap feature and SIL 3 compliance ensure continuous operation, vital for grid reliability.

Pharmaceutical plants leverage the Triconex 8111 for batch processing, adding slots for flow sensors to monitor mixing operations. Its compact design and fault tolerance excel in cleanroom environments, ensuring process control accuracy and compliance with stringent safety standards.

Triconex 8100-1 – Main TMR chassis, serving as the primary hub for 8111 expansion connections.

Triconex 3504E – 64-point digital input module for high-density sensor integration in 8111.

Triconex 3625 – Digital output module for actuator control, expanding 8111’s output capabilities.

Triconex 3700A – Analog input module for mixed-signal applications within the chassis.

Triconex 4351B – Communication module for Modbus networking, enhancing 8111 connectivity.

Triconex 9566-810 – Input termination panel for streamlined field wiring to 8111 modules.

Triconex 9662-810 – Output termination panel for balanced I/O expansion.

Triconex 8300A – Power supply module to ensure redundant power for 8111 operations.

Before setting up the Triconex 8111, verify TriBus cable compatibility with your main chassis and ensure firmware aligns with v9–v11 using TriStation software. Test grounding to meet IEC 61508 requirements, and confirm dual 24 VDC feeds have ripple below 200 mV. Leave 2 inches of clearance around the rack for ventilation, especially in high-temperature settings, to prevent module overheating.

Maintenance for the Triconex 8111 involves quarterly checks of diagnostic LEDs for power and bus status, logging any anomalies for review. Every six months, inspect I/O connectors for corrosion, tightening screws to 0.5 Nm, and clean with isopropyl alcohol if dust accumulates. Annual SIL 3 tests, simulating module faults via TriStation, validate redundancy without disrupting workflows. These practical steps ensure the chassis remains a reliable extension of your automation system, minimizing maintenance demands while upholding performance.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626