Description

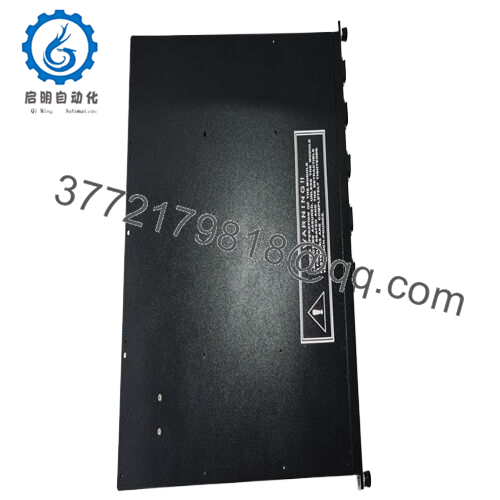

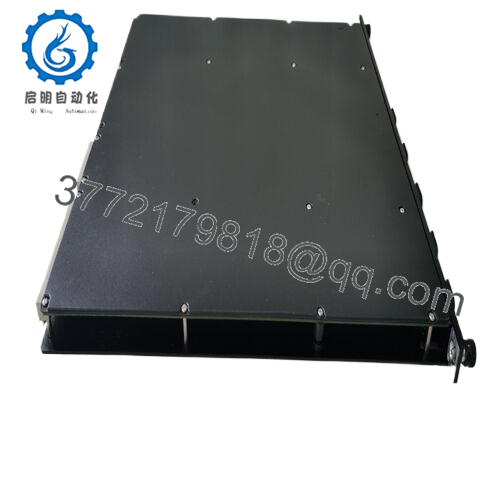

Triconex 4351B is a critical component of the Triconex Safety Instrumented System (SIS), serving as a reliable bridge between field equipment and the central control platform. It interfaces with sensors that monitor key parameters such as temperature, pressure, flow rate, and chemical composition, as well as actuators that control valves, pumps, and other critical equipment. By seamlessly integrating with the Triconex backplane architecture, this module enables efficient data flow and communication throughout the entire automation stack, facilitating real-time monitoring and precise control of industrial operations.

4351B

Main features and advantages:

The core of Triconex 4351B lies in its advanced Triple Modular Redundancy (TMR) technology. This design concept triples the number of key components within the module, creating a highly resilient system. When one of the modules fails, the system can continue to operate without interruption by relying on redundant paths. This significantly reduces the risk of unplanned downtime, which is crucial for industries that operate 24/7 and any disruption could have far-reaching impacts.

The Triconex 4351B is also equipped with the most advanced self diagnostic function. These diagnostic functions continuously monitor the health status of the module and detect potential issues such as component degradation, electrical fluctuations, or communication errors in the early stages. Once an anomaly is detected, the self diagnostic system will immediately issue an alert to the operator, enabling proactive maintenance and minimizing the possibility of unexpected system failures. In addition, the module supports multiple industry standard protocols, including Profibus, Modbus, and HART, ensuring compatibility with a large number of existing and new field devices, making it highly adaptable to different industrial settings and future expansion needs.

Its sturdy structure combined with TMR technology ensures long-term reliability even in the harshest environments such as extreme temperatures, high electrical noise, and mechanical vibrations. This reliability directly translates into reducing unplanned downtime, maximizing production output, and minimizing economic losses. For example, in a 24/7 operating refinery, Triconex 4351B can ensure smooth refining processes, avoid costly interruptions, and ensure timely production of refined products.

The advanced self diagnostic function of Triconex 4351B significantly simplifies maintenance work. Engineers do not need to spend hours manually troubleshooting, but can quickly identify and solve problems, thereby reducing maintenance time and costs. This not only improves the efficiency of maintaining the team, but also allows for more efficient use of resources. In addition, its compatibility with multiple protocols and a large number of devices makes integration into existing automation systems simple and clear, reducing engineering costs and achieving seamless upgrades as industrial processes evolve.

4351B

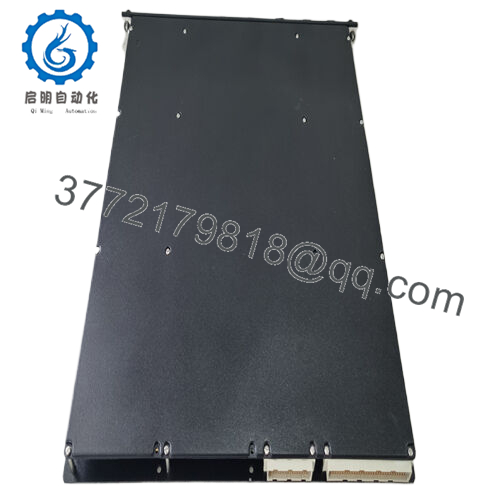

Technical specifications:

Model 4351B

Brand Triconex

Type safe I/O module

Certification CE, RoHS

Supports protocols Profibus and Modbus

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

4351B

Application areas:

It monitors and controls key processes on offshore platforms, such as oil extraction, separation, and transportation, as well as onshore refineries, overseeing the complex operations of refining crude oil into various products. Its ability to handle complex signal processing and maintain signal integrity in harsh marine and industrial environments ensures the safe and efficient operation of the entire oil and gas production chain.

In the field of nuclear power generation, Triconex 4351B plays a crucial role in ensuring the safe and reliable operation of nuclear power plants. It manages I/O signals from various components of the nuclear reactor, monitors and controls parameters to prevent accidents and ensure stable power generation.

4351B

Related products:

Triconex 4351B – HC – With an increased number of I/O channels, it is suitable for large industrial projects that require extensive data processing and control, such as large chemical complexes or integrated energy plants.

Triconex 4351B – EX – Designed specifically for explosive and hazardous environments, with enhanced explosion-proof capabilities and certification, it is highly suitable for use in petrochemical plants, oil storage facilities, and other high-risk areas.

Triconex 4351B – FAST – Provides faster signal processing speed, making it ideal for applications that require high real-time response, such as high-speed production lines or fast response control systems in industrial automation.

Triconex 4351B – LOWP – Optimized for low power consumption, reducing the overall energy consumption of the system, promoting energy-saving measures and sustainable industrial operations.

Triconex 4351B – COMP – Suitable for installations with limited space, such as control cabinets or onboard automation systems in small industrial settings.

Triconex 4351B – RED++- provides enhanced redundancy capabilities beyond standard TMR, further improving system reliability and making it suitable for critical mission applications where any downtime could have catastrophic consequences, such as military command centers or aerospace control systems.

4351B

Installation and maintenance:

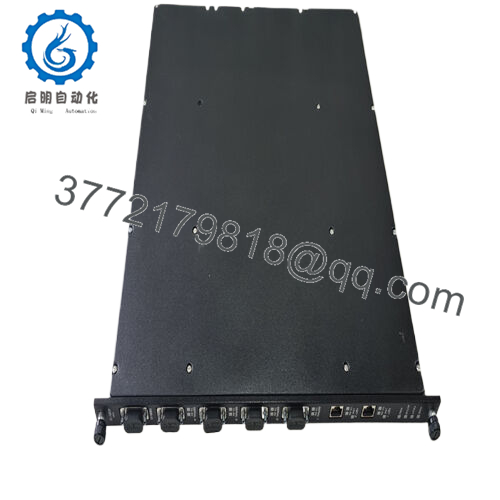

Before installing Triconex 4351B, a thorough compatibility check must be conducted on the existing Triconex system. Verify if there are available slots on the backplane and ensure that the firmware for the control platform is up-to-date. This ensures seamless integration and prevents potential compatibility issues that may interfere with system operation. In addition, please carefully check the electrical requirements of the module, including voltage and current ratings, to ensure that the power supply meets the specified parameters. Adequate space should be reserved to ensure proper ventilation, as modules generate heat during operation, and effective thermal management is crucial for their optimal performance.

For ongoing maintenance, please regularly monitor the LED status indicator on Triconex 4351B to quickly identify any abnormal conditions. Regularly inspect connectors and cables to ensure they are securely connected and free from damage or corrosion. Use the built-in self diagnostic function of the module for regular diagnostic testing to check the integrity of its components and verify their performance. Following the manufacturer’s recommended regular maintenance plan, including firmware updates, will help extend the lifespan of Triconex 4351B and ensure its continued reliable operation.

Other product models of Triconex:

TRICONEX 8111

TRICONEX 4351B

TRICONEX 3008

TRICONEX 3625C1

TRICONEX 3503E

TRICONEX 3700A

TRICONEX 3625

TRICONEX 4200

TRICONEX RXM4200-3

TRICONEX 8310

TRICONEX 3626X

TRICONEX MP3101S2

TRICONEX PLM3900N

TRICONEX 8310

Triconex IMFF4703x

TRICONEX 3351S2

Triconex 3603E

Triconex Mar-01

TRICONEX 3401S

TRICONEX 3401S2

TRICONEX 3009

TRICONEX RXM4201

Triconex 3501T

TRICONEX 3503E

TRICONEX 3503E

TRICONEX 3504Е

Triconex 3604E

TRICONEX 3623T

Triconex 3636R

TRICONEX 3704E

TRICONEX 3704Е

TRICONEX 3723X

TRICONEX 3805E

TRICONEX 3805E

TRICONEX 3805E

Triconex 3805E

Triconex 3806E

TRICONEX 8310N2

Triconex 4210

Triconex 4211

TRICONEX 9566-810

TRICONEX 3351S2

TRICONEX 3511

TRICONEX 3664

TRICONEX 3625C1

TRICONEX 3008

Triconex 3607E

TRICONEX 3604E

TRICONEX 3009

TRICONEX 3624

TRICONEX RXM4201

TRICONEX 8310

TRICONEX 4351B

TRICONEX 4351B

TRICONEX 4351B

TRICONEX CIM3211S2

TRICONEX DI3301S2

TRICONEX A03481S2

TRICONEX 3805H

TRICONEX 3506X

TRICONEX 3626X

TRICONEX 4355X

TRICONEX 7400247-020

Triconex 8311

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626