Description

Real-World Use & Application Scenarios

The TRICONEX 4211 remote extender module is widely deployed in large-scale industrial automation environments where safety and reliability are paramount. Industries such as oil and gas refining, petrochemical processing, power plants, and pharmaceutical manufacturing face challenges including physically distributed assets and complex safety systems requiring extended signal reach without sacrificing data integrity or response speed. The TRICONEX 4211 addresses these by enabling remote connection of safety instrumented system I/O modules back to the central control system over fiber optic communication.

Applicable in safety instrumented systems (SIS) where emergency shutdown, fire and gas detection, or turbine control must operate without interruption, this module efficiently transmits digital and analog signals from remote field sites up to 7.5 miles (12 kilometers) away. It supports various harsh industrial environments by reducing wiring complexity, preventing signal degradation, and improving diagnostic capabilities. The TRICONEX 4211 is suited for industries using TRICONEX platforms that demand redundancy and fault tolerance, supporting seamless integration into triple modular redundancy (TMR) systems for maximum availability and compliance with global SIL 3 safety standards.

Product Introduction & Positioning

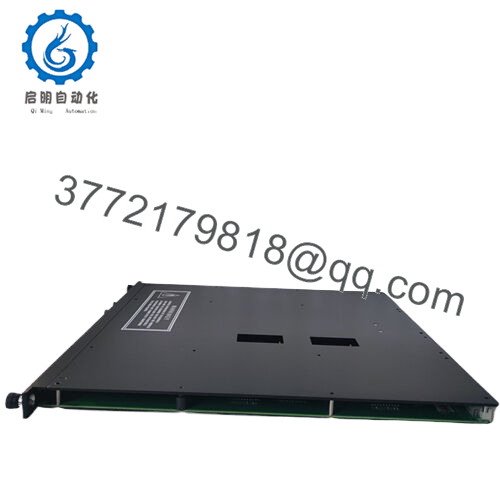

The TRICONEX 4211 functions as a remote extender module (RXM) within TRICONEX’s safety instrumented system architecture. It acts as an intermediary communication node, extending the digital and analog I/O signal capabilities of TRICONEX controllers to remote field locations via fiber optic links. By converting signals for transmission over long distances with minimal latency, it enables distributed safety applications without compromising system reliability.

Engineers rely on the 4211 for its high-speed processing, robust communication, and seamless integration with TRICONEX control platforms across multiple remote sites. Its design supports single-mode fiber with ST connectors and includes multiple diagnostic indicators to monitor communication integrity actively. Positioned as a vital component in extended safety systems, the TRICONEX 4211 helps simplify control panel architecture, reduces wiring complexity, and enhances maintainability while preserving the high availability and fault tolerance expected from TRICONEX’s TMR-based systems.

- 4211

Key Technical Features & Functional Benefits

The TRICONEX 4211 boasts extensive I/O support and high-speed signal processing, ensuring rapid and accurate transmission of field data to the main controller. Its fiber optic communication interface with ST connectors supports distances up to 12 kilometers with minimal signal loss, enabling flexible placement of remote I/O devices in distributed plant layouts. The inclusion of six fiber connectors enhances system scalability and redundancy options.

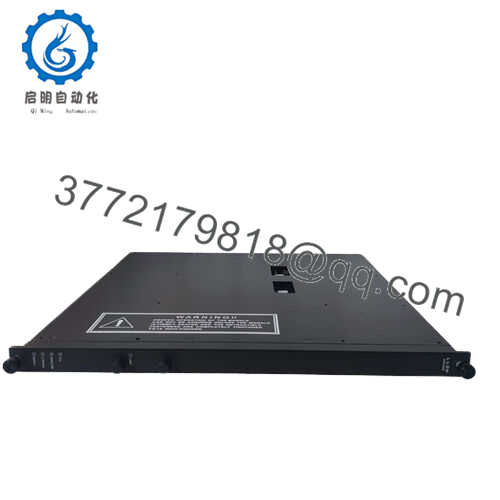

Durability and reliability are core strengths of the 4211, with its operation maintained over a wide temperature range suitable for industrial environments. Comprehensive diagnostic LEDs provide real-time status updates including PASS, FAIL, ACTIVE, and transmission indicators (TX, RX1–3), which aid preventative maintenance and quick fault isolation. The module’s high tolerance to interference and electrical noise combined with its triple modular redundancy backbone ensures consistent, fail-safe communication in critical safety loop applications.

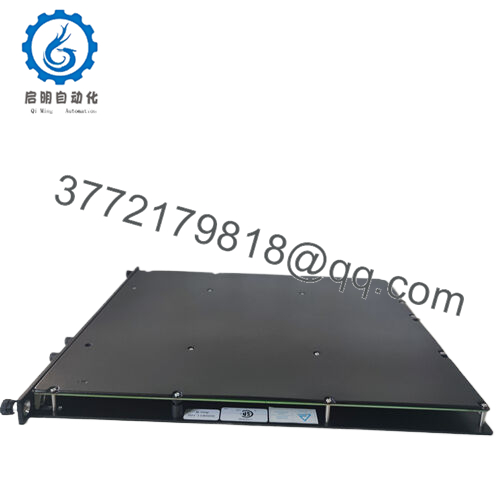

Compact and lightweight, the TRICONEX 4211 simplifies installation, occupying minimal panel space with dimensions approximately 20 cm x 11 cm x 9.3 cm and weighing about 1.05 kg. This streamlined form factor facilitates integration into standard TRICONEX chassis and communication panels without overcrowding. Its robust construction and compliance with international safety standards make it a long-term reliable solution for expanding TRICONEX SIS applications to geographically dispersed facilities.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 4211 |

| Brand | TRICONEX |

| Product Type | Remote Extender Module (RXM) |

| Communication Interface | Fiber optic, single-mode with ST connectors |

| Maximum Cable Length | 7.5 miles (12 kilometers) |

| Number of Connectors | 6 |

| Diagnostics Indicators | PASS, FAIL, ACTIVE, TX, RX1, RX2, RX3 |

| Operating Temperature | -20°C to +70°C |

| Dimensions (L x W x H) | 20 cm x 11 cm x 9.3 cm |

| Weight | Approximately 1.05 kg |

| Compliance | IEC 61508 SIL 3, TÜV certified |

| Power Supply | As per TRICONEX platform requirements |

| Environmental Rating | Suitable for industrial environments |

Related Modules or Compatible Units

TRICONEX 9566-810F – Digital input termination panel complementing extended I/O setups.

TRICONEX 3625 – Digital output module interfacing with remote and local I/O modules.

TRICONEX 4351B – Safety controller module managing logic for expanded systems.

TRICONEX 8312 – Redundant power supply module enhancing system fault tolerance.

TRICONEX 9561-810 – Analog input module supporting complex process measurements.

TRICONEX 9662-810 – Communication module facilitating system-wide networking.

Installation Notes & Maintenance Best Practices

Installation of the TRICONEX 4211 requires careful routing of single-mode fiber optic cabling to maintain signal integrity over long distances up to 12 kilometers. Ensure clean, dust-free environments at fiber connectors and proper handling to avoid damage. The module should be mounted within a TRICONEX-compatible rack with adequate ventilation and clearance to prevent overheating. Power and communication connections must be verified for compliance with TRICONEX hardware specifications to avoid interruptions.

Maintenance routines should include periodic inspection of fiber optic connectors and cleaning to prevent losses. Diagnostic LEDs provide a quick health check; any FAIL or communication error indicators should trigger prompt troubleshooting using TRICONEX’s diagnostic software tools. Scheduled functional testing of extended remote I/O links ensures ongoing reliability. Firmware updates provided by TRICONEX should be applied systematically to maintain cybersecurity and performance.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626