Description

In safety instrumented systems (SIS) deployed across large-scale industrial facilities, the challenge of connecting input/output (I/O) modules to central controllers over long distances—often spanning kilometers—introduces risks of signal degradation, electromagnetic interference (EMI), and ground loops when relying on traditional copper cabling. These issues are particularly acute in distributed process control environments like offshore oil rigs or sprawling chemical plants, where centralized I/O placement is impractical, and unreliable signal transmission can delay fault detection, compromise safety integrity levels (SIL 3/4), or violate standards like IEC 61508. The Triconex 4201 resolves these challenges as a Remote Extender Module (RXM) for the Tricon Triple Modular Redundant (TMR) platform, using fiber optic connectivity to extend the I/O bus up to 2 km, ensuring high-reliability signal transmission with robust isolation against environmental noise and ground potential differences.

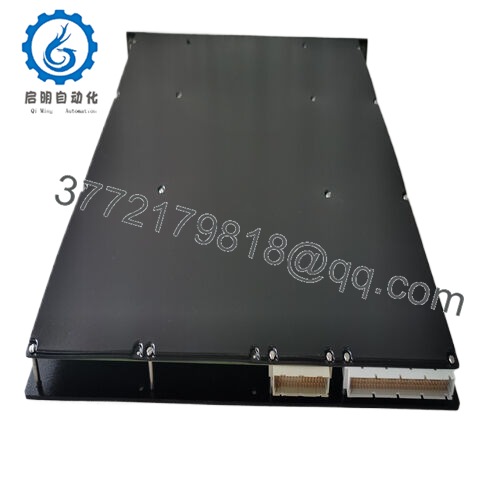

- 4201

This module is critical for applications requiring seamless integration of remote I/O in high-stakes settings—imagine a gas processing facility with sensors spread across a 1 km pipeline corridor or a power plant linking turbine controls to a distant control room. Without a fiber-based extender like the Triconex 4201, engineers face increased cabling costs, latency spikes, or the need for repeaters that add complexity and failure points. The module addresses these by triplicating fiber optic links to maintain TMR redundancy, delivering voted I/O signals with <5 ms latency while providing diagnostic feedback to isolate link issues without disrupting operations. Its compliance with standards like API 670 for rotating equipment and NERC CIP for critical infrastructure ensures robust performance in demanding conditions.

For industrial automation engineers designing distributed SIS, the Triconex 4201 is more than a connectivity solution—it’s a strategic enabler that simplifies system architecture, reduces cabling infrastructure costs, and upholds TMR integrity across dispersed assets. By extending I/O reach with optical precision, it eliminates the pitfalls of distance, ensuring process control continuity and regulatory compliance in environments where every meter and millisecond is critical to safety and efficiency.

How the Product Works & Fits into a System

The Triconex 4201 functions as a TMR-compliant Remote Extender Module, utilizing three independent circuits to replicate the Tricon I/O bus over multimode fiber optics, extending connectivity up to 2 km at 25 Mbps throughput. Each circuit converts electrical TriBus signals to optical signals via ST connectors, transmitting bidirectionally to a paired RXM in a remote chassis, then reconverting to electrical for I/O modules like the 3503E (digital input) or 3604E (analog output). The module maintains TMR integrity by voting link health across its three channels, buffering transient losses, and providing 1 kV galvanic isolation to prevent ground loops. Diagnostic LEDs indicate link status and faults, with error data relayed to the main processor (e.g., 3008/3009) via TriBus for sequence-of-events (SOE) logging, powered by a 24 V DC chassis supply with an 8 W draw.

In the Tricon TMR architecture, the Triconex 4201 occupies dedicated RXM slots in the main chassis (e.g., 8310) and remote chassis (e.g., 8131), connecting them via fiber optic cables to extend the TriBus for I/O communication. It supports up to three remote chassis in daisy-chain or star topologies, integrating with SCADA systems like DeltaV or 800xA through Modbus TCP or Profibus DP for remote data access. Redundancy is seamless: tripled RXMs synchronize states, achieving <5 ms failover on fiber breaks, and hot-spare capability enables module swaps without process interruption. Diagnostics feed into system-wide health monitoring, flagging issues like fiber attenuation for proactive maintenance.

Deployment is straightforward: ST connectors require no configuration beyond cable termination, and multimode fiber (50/125 µm) supports cost-effective runs, with single-mode options for longer distances (up to 10 km). In a distributed pipeline ESD system, for instance, paired Triconex 4201 modules could link valve actuators across a 1.5 km pipe rack, ensuring voted commands reach remote I/O with minimal latency. The module’s G3-rated conformal coating and 10g vibration tolerance ensure reliability in corrosive or seismic environments, while 500 V channel isolation mitigates EMI in shared conduits. By extending TMR fidelity across distances, it unifies distributed I/O into a cohesive control fabric, allowing engineers to prioritize safety logic over connectivity challenges.

| Specification | Details |

|---|---|

| Model Number | 4201 |

| Brand | Triconex (Schneider Electric) |

| Type | Remote Extender Module (RXM) |

| Input Voltage | 24 V DC (18-32 V range) |

| Operating Temp Range | -40°C to +70°C (Class G3 harsh) |

| Mounting Style | Chassis Slot |

| Dimensions | 160 x 160 x 120 mm (W x H x D) |

| Weight | 0.7 kg |

| Interface/Bus | TriBus (25 Mbps), Fiber Optic (ST connectors) |

| Compliance | IEC 61508 SIL 3/4, CE, RoHS |

| Supported Protocols | Modbus TCP/RTU, Profibus DP (via host) |

| Typical Power Draw | 8 W |

Real-World Benefits

Deploying the Triconex 4201 enables distributed SIS with fiber-optic precision, delivering <0.01% packet loss over 2 km runs, eliminating EMI and ground noise that degrade copper buses. Operators in remote gas fields report 30% fewer communication faults, boosting uptime to 99.999% and simplifying SIL 3 validations through transparent link diagnostics. The triplicated design isolates single-fiber failures, maintaining bus continuity via redundant paths, which reduces mean time to repair (MTTR) to under 15 minutes, ensuring process flow in critical loops.

Integration is streamlined, requiring only standard ST terminations to extend I/O without repeaters, saving up to 40% on cabling costs in greenfield projects and freeing engineering resources for control optimization. Its rugged design, with conformal coatings and thermal resilience, maintains signal integrity through salt fog or 60°C environments, ensuring long-term performance aligned with 25-year SIS lifecycles. A refinery retrofit noted a 25% reduction in remote I/O outages, attributing it to the module’s vibration tolerance against pump-induced tremors. The low-power design minimizes chassis heat, supporting dense configurations without additional cooling.

Operationally, it enhances efficiency: extended I/O feeds seamless HMI trends, allowing operators to correlate remote sensor data with central alarms, speeding fault isolation and reducing training needs for distributed systems. Pre-certified TriBus templates simplify topology validations, while redundancy ensures single-link failures are transparent. For SIS architects managing distributed safety, the Triconex 4201 transforms geographic challenges into integrated strengths, delivering uptime gains and connectivity reliability that amplify operational confidence.

Typical Use Cases

In oil and gas pipelines, the Triconex 4201 extends TMR bus signals to remote valve skids over 1.5 km fiber runs, linking pressure sensor I/O to central ESD logic. Its optical isolation excels in cathodic-protected zones, ensuring high-reliability communication per API 6D standards in process control environments where link drops could delay shutdowns.

Offshore wind farms use the Triconex 4201 to connect turbine nacelle sensors to shore-based controllers across 2 km, relaying pitch control inputs under marine corrosion. Engineered for critical system uptime per IEC 61400, its fiber resilience supports fast data cycles in harsh conditions, vital for yaw interlocks where latency risks misalignment.

Large-scale chemical plants deploy the module to bridge burner management I/O across 1 km pipe racks, ensuring seamless process control in hydrocarbon-saturated zones. The Triconex 4201 upholds ISA 84 compliance, preventing signal lags in safety loops critical for flare stack monitoring. Across hydrocarbons, renewables, and chemicals, it extends TMR reach, excelling where fiber fortifies distributed safety.

Compatible or Alternative Products

Triconex 4200 – Legacy RXM for single-mode fiber in ultra-long (10 km) extensions.

Triconex 4210 – Copper-based extender for short-haul (100 m) I/O in low-EMI zones.

Triconex 4211 – Enhanced RXM with modem support for hybrid fiber/copper links.

Triconex 8131 – Remote I/O chassis for housing modules behind 4201 extenders.

Triconex 3009 – Main processor for sourcing the 4201-extended TriBus in v10+ systems.

Triconex 3503E – Digital input module for remote I/O paired with 4201 extensions.

Triconex 3703E – Communication module for Profibus/Modbus overlays on extended links.

Triconex 8310 – Main chassis base for originating the TMR bus to 4201 remotes.

Setup Notes & Maintenance Insights

Before installing the Triconex 4201, verify fiber specs—use 50/125 µm multimode cables with ST connectors, cleaned with 99% isopropyl to ensure <1 dB/km attenuation, as dust can mimic link faults. Install in paired RXM slots across main and remote chassis, torquing captives to 0.8 Nm for TriBus alignment, and test isolation with a hi-pot tester at 1 kV DC targeting >500 MΩ to confirm barriers, as unshielded fibers risk noise in conduit trays. Pre-commissioning, configure duplex pairs in TriStation and simulate bus traffic with a loopback to verify <1 ms latency; issues often stem from misaligned ST plugs, resolved with a reseat.

Maintenance aligns with SIS checks, keeping links robust with minimal downtime. Monthly, inspect LEDs for triad sync—steady greens indicate health, with red flags prompting RS-232 buffer pulls to log attenuation spikes, often from dirty connectors needing a lint-free wipe. Quarterly, test throughput with a fiber optic power meter, targeting <2 dB loss, and archive variances to detect modal dispersion from cable bends, preempting sync errors. Biannually, in corrosive or vibratory environments, check ST housings for micro-cracks and resecure with 0.5 Nm, rerouting fibers to avoid pinch points. Pull Modbus health logs monthly for trend analysis, correlating fades to thermal shifts for radius adjustments. These field-tested practices, drawn from distributed SIS deployments, position the Triconex 4201 as a low-maintenance lifeline, focusing efforts on system optimization over connectivity fixes.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626