Description

The Triconex 3721 is widely employed in industrial automation settings where the accurate and reliable monitoring of analog signals is crucial to maintaining process safety and control integrity. It is predominantly found in safety instrumented systems within industries such as oil and gas, petrochemical, power generation, and pharmaceuticals. These sectors demand continuous measurement of critical process variables—like pressure, temperature, and flow rates—that directly impact operational safety and environmental compliance. The Triconex 3721 excels in these environments by converting analog sensor signals into digital inputs for fault-tolerant processing, ensuring operators and safety systems react promptly to abnormal conditions. Thanks to its ability to handle diverse input types and maintain signal integrity under harsh conditions, this module is essential where precision and fail-safe performance are non-negotiable. It is used extensively in control rooms alongside Triconex’s Trident platform to support emergency shutdown systems, burner management, and critical alarm monitoring—all tasks that require zero tolerance for data errors or downtime. The Triconex 3721 is recognized for its compatibility in control systems where SIL 3 certification and robust diagnostics are requisites, embedding it deeply into the architecture of modern safety-critical automation.

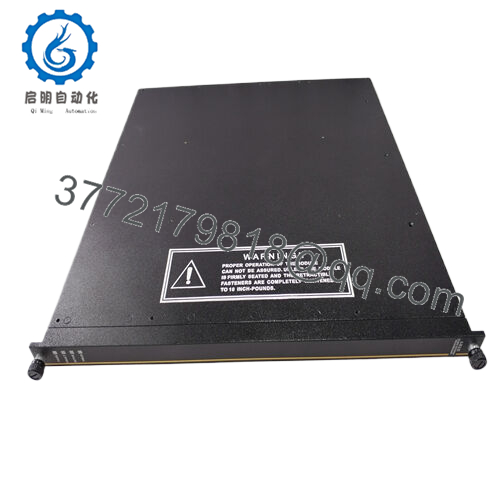

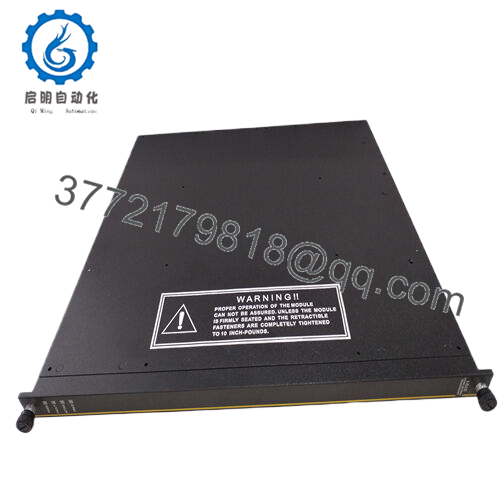

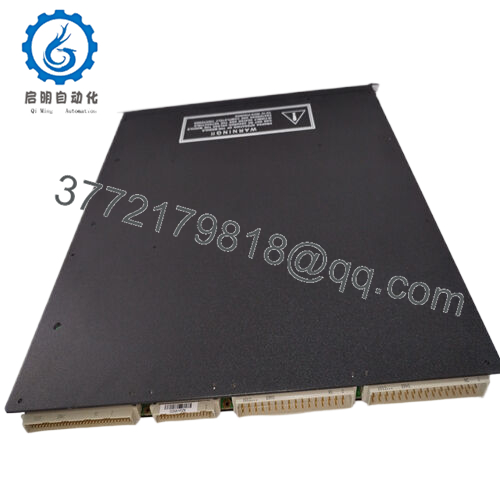

At its core, the Triconex 3721 is an analog input module designed to integrate seamlessly into Triconex Trident safety instrumented systems (SIS). This module acts as the primary interface for signal acquisition from analog field sensors, converting voltage or current measurements into digital data that Triconex’s triple modular redundant (TMR) processors analyze. The 3721 occupies a critical position within the modular SIS architecture, typically installed in standard I/O racks where it interfaces directly with sensor wiring. It supports 32 differential input channels that can be programmed to various resolutions (12 or 14 bits), allowing precise measurement tailored to application needs. The module is compatible with Triconex v10.2 and later system versions and forms an integral component that enhances system scalability and flexibility. Engineers value the Triconex 3721 for its fault-tolerant design, high measurement accuracy, and broad input voltage range options, making it adaptable to a wide variety of analog signals encountered in industrial processes. Its role expands beyond mere signal conversion as it actively participates in system diagnostics and error detection, contributing to overall safety and reliability.

- 3721

The technical prowess of the Triconex 3721 lies in its precise analog signal acquisition and robust fault tolerance, designed specifically for safety-critical applications. It supports up to 32 differential, DC-coupled input points with programmable resolution offering 12-bit or 14-bit precision to suit varying measurement requirements. The input voltage range spans from 0 to 5 VDC or -5 to +5 VDC, accommodating sensors producing bipolar signals—a crucial feature for complex industrial measurements. Accuracy is maintained within ±0.15% of full scale across normal operating temperatures (0° to 60°C), ensuring dependable readings for process control decisions. The module is engineered to withstand harsh industrial conditions with an operating range extending from -40°C to +70°C and resistance to shock and vibration in accordance with IEC standards. Isolation ratings of 1500 Vrms between field inputs and logic circuitry improve noise immunity and protect against electrical faults. Its input filter and debounce times are programmable to reject spurious signals and transient noise effectively. Long-term reliability is further supported through self-diagnostic capabilities and continuous monitoring of input channel health, reducing maintenance interventions. The compact, rack-mounted form factor facilitates straightforward integration, while its power consumption remains efficient, typically under 15 watts. The consistent high performance and rugged design of the Triconex 3721 make it an indispensable asset in maintaining the integrity of safety instrumented control loops.

| Parameter | Value |

|---|---|

| Model | Triconex 3721 |

| Brand | Triconex (Schneider Electric) |

| Product Type | Analog Input Module |

| Number of Input Channels | 32 differential, DC-coupled |

| Input Voltage Range | 0 to 5 V DC or -5 to +5 V DC |

| Resolution | Programmable 12 or 14 bits |

| Input Update Rate | 10 milliseconds |

| Accuracy | ±0.15% of full scale (0°C to 60°C) |

| Isolation | 1500 Vrms (field to logic) |

| Operating Temperature | -40°C to +70°C |

| Power Consumption | < 15 watts |

| Mounting | Rack-mounted |

| Certifications | SIL 3 (IEC 61508), CE, RoHS |

| Weight | Approx. 1.36 kg |

| Dimensions | Approx. 2.2 cm x 40.8 cm x 40 cm |

The Triconex 3721 pairs well with complementary modules to form comprehensive safety systems:

Triconex 3601 – Processor module that executes safety logic using inputs from 3721.

Triconex 3701 – Analog output module working with 3721 inputs to control actuators.

Triconex 3720 – Alternative analog input module for single-ended signals.

Triconex 3740 – Digital output module supporting alarms based on 3721 inputs.

Triconex 4210 – Remote extender module for extending I/O signals including those from 3721.

Triconex 4000 – Power supply unit supporting stable operation of modules including 3721.

Before installing the Triconex 3721, careful attention must be paid to cabinet space, cooling, and rack slot availability—ensuring sufficient clearance for heat dissipation and cable management. Grounding practices are essential to prevent electrical noise that could compromise analog signal fidelity. The module’s rack-mounted design requires secure mechanical fixation and careful wiring following Triconex guidelines. Regular maintenance should focus on inspecting LED status indicators, monitoring self-diagnostics via TriStation software, and verifying signal integrity through system testing. Firmware updates, when applicable, must be coordinated with plant downtime schedules to avoid interruptions. Cleaning of connectors and visual inspections for wear or corrosion protect against signal degradation. Incorporating periodic preventive maintenance routines extends module lifespan and safeguards against unforeseen failures.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626