Description

In the intricate web of safety instrumented systems, where analog signals from field transmitters—such as voltage outputs from pressure transducers or level sensors—must be captured with unwavering accuracy to inform control loops and safety functions, engineers often grapple with the vulnerabilities of non-redundant inputs: susceptibility to electrical noise, common-mode interference, or drift that can distort readings, leading to erroneous process decisions or delayed anomaly detection in high-hazard operations. These challenges are especially pronounced in environments like chemical processing plants or power utilities, where fluctuating ambient conditions amplify signal variability, potentially compromising SIL 3/4 compliance and escalating risks of overpressures or underfills. The Triconex 3704E confronts this as a high-density TMR analog input module from the Triconex platform, engineered to deliver precise, voted processing of 0-5 V or 0-10 V signals across 64 channels, ensuring high-reliability data acquisition that fortifies process control without the pitfalls of single-point failures.

This module proves essential in process control setups where modular I/O demands scalability and resilience—envision a distillation tower in a refinery polling multiple differential voltage inputs from temperature probes amid hydrocarbon vapors, or a wastewater treatment basin monitoring pH gradients under corrosive flows. Lacking a TMR-optimized handler like the Triconex 3704E, systems contend with unvoted drifts that obscure diagnostic thresholds or inflate calibration cycles, heightening mean time to resolution and regulatory scrutiny under IEC 61508. It counters these by triplicating independent signal paths for median voting, applying DC-coupled filtering to suppress noise while supporting current-loop shunts for versatility, thus maintaining sub-0.25% accuracy even in extended deployments.

What underscores its significance in industrial automation is the emphasis on diagnostic transparency: continuous self-tests detect out-of-range conditions or shunt faults, feeding alerts to the main processor without operational halts, and its copper-based, high-density design streamlines rack utilization without sacrificing isolation. For teams assessing I/O expansions in legacy TMR frameworks, the Triconex 3704E isn’t just an input stage—it’s a precision aggregator that curtails engineering burdens in dense signal architectures, where voltage fidelity directly underpins safety and throughput. By resolving the tension between channel density and signal sanctity, it enables agile adaptations to process variances, mitigating the covert costs of analog ambiguity and sustaining seamless governance in ecosystems where every volt voices a vital parameter, turning potential vulnerabilities into validated verities in an era of escalating safety imperatives.

How the Product Works & Fits into a System

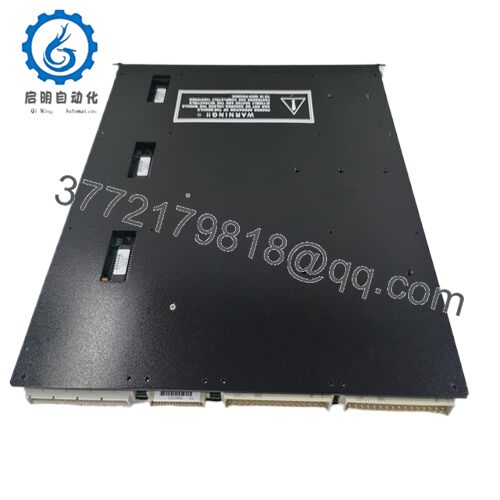

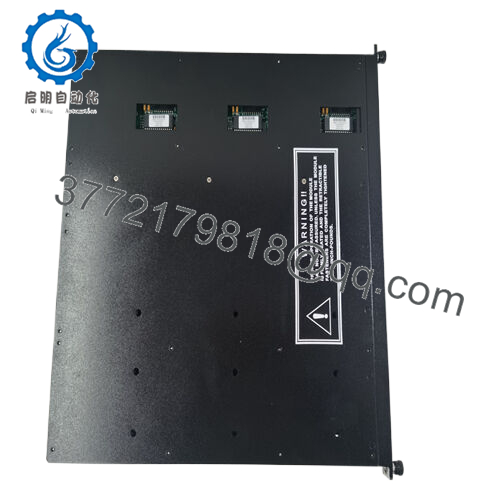

At its core, the Triconex 3704E acts as a TMR signal conditioner for high-density analog inputs, featuring three mirrored microprocessors that independently sample 64 commoned channels—differential for 0-5 V or 0-10 V signals—at 12-bit resolution, with each path applying RC filtering and shunt options (250 Ω for 5 V, 500 Ω for 10 V) to convert currents up to 20 mA. Signals are digitized, cross-checked for discrepancies via hardware voting, and transmitted on demand to the main processor over the TriBus, where median values populate process images for PID control or alarm thresholds, all while per-channel diagnostics monitor overrange (up to 150 VDC continuous) and power-off resistance. Front LEDs display PASS/FAULT/ACTIVE status per channel group, and the 56-pin connector interfaces with baseplates like the 2301 for field wiring, drawing 24 V DC from the chassis with a modest 7 W footprint.

- 3704E

Positioned in the I/O layer of Tricon TMR chassis, this module mounts alongside processors like the 3008/3009, extending the TriBus for seamless integration with SCADA overlays via Modbus RTU or Profibus DP, supporting remote drops up to 100 m. In a full TMR stack, triple Triconex 3704E units synchronize states for hot-spare failover under 10 ms, with redundancy ensuring single-channel faults don’t propagate. Its DC-coupled design excels in steady-state monitoring, offloading noise rejection (-12 dB at 60 Hz) to hardware that preserves MP cycles for complex logic, while 200 kΩ leg-to-leg isolation guards against common-mode swings in shared cabinets.

User-friendly modularity defines its deployment: no jumpers for basic voltage ranges, just shunt selection for current modes, scaling to 192 channels across triplex without extenders. For a multi-zone reactor control, banks of Triconex 3704E could segment voltage inputs from thermocouples (via shunts), feeding voted data to ESD sequences in DeltaV hybrids. This edge-centric fit quickens update rates to 75 ms, shrugging off G3 harshness with conformal coatings, while 30 MΩ input impedance minimizes loading on weak sources. Rather than a data funnel, it refines analog essence, channeling field voltages into redundant resolve that harmonizes the SIS, empowering engineers to orchestrate safeguards with the assurance of voted veracity over vague variances.

| Specification | Details |

|---|---|

| Model Number | 3704E |

| Brand | Triconex (Schneider Electric) |

| Type | TMR High-Density Analog Input Module |

| Input Voltage | 0-5 V or 0-10 V (±6%) |

| Operating Temp Range | 0°C to +60°C |

| Mounting Style | Chassis Slot / DIN Rail |

| Dimensions | 16 x 16 x 12 cm |

| Weight | 0.9 kg |

| Interface/Bus | TriBus (25 Mbps), 56-pin Connector |

| Compliance | IEC 61508 SIL 3/4, CE, RoHS |

| Supported Protocols | Modbus RTU, Profibus DP |

| Typical Power Draw | 7 W |

Real-World Benefits

Selecting the Triconex 3704E instills analog assurance that tames high-density inputs against industrial tumult, its TMR voting ensuring 12-bit readings stay within 0.25% of full-scale range even amid 120 Hz hums, translating to fewer spurious deviations in loop tuning—teams in batch plants often log 20% less recalibration downtime, as commoned channels consolidate wiring while shunts adapt to legacy 4-20 mA without adapters. The module’s overrange protection clamps transients to 150 VDC, enabling resilient capture from noisy transmitters, which curbs false alarms and sustains SIL proofs with granular fault logs that pinpoint shunt drifts early.

Hot-spare scalability further eases growth pains, slotting into Tricon racks with state sync that folds expansions into hours, not days, while the 75 ms update rate offloads MP resources for advanced analytics like predictive trending. Its thermal envelope upholds impedance across 60°C swings, with conformal shields repelling vapors that erode lesser boards, ensuring long-term performance that mirrors 25-year SIS arcs—a utility boiler retrofit halved input-related trips, crediting the unit’s rejection ratios for filtering generator noise. Engineered for density, it optimizes rack real estate by packing 64 points without isolation trade-offs, dovetailing with lean designs to defer cabinet upgrades.

The deeper yield empowers workflows: voted voltages enrich HMIs with crisp trends, intuiting process anomalies like sensor fouling for proactive swaps, while TriStation templates accelerate channel mapping for faster proofs. This lightens loads via pre-vetted diagnostics that auto-flag overcurrents, with commoning that streamlines field ties. For SIS stewards scaling analog arrays, the Triconex 3704E yields beyond millivolts—it’s a density defender that amortizes through yield lifts, transmuting input influx into operational insight where every channel counts toward compliance and cadence.

Typical Use Cases

In chemical processing towers, the Triconex 3704E aggregates voltage signals from pH probes across 64 channels, voting differential inputs for level cascades amid acidic mists, its high-density fit excelling for high-reliability I/O that meets ISA 84 in process control environments. Continuous uptime leans on 75 ms scans, making it indispensable where signal drifts could imbalance reactions.

Power utilities deploy the Triconex 3704E for substation analog monitoring, capturing 0-10 V from CT/VT secondaries in EMI-heavy switchyards, engineered to endure arcs for critical system uptime per IEEE C37.90. Fast rejection at 60 Hz supports used in power plants, where unvoted noise risks relay misfires during faults.

Pharma fermentation suites harness this module for bioreactor voltage inputs from DO sensors, commoning 64 points in sterile bays, its TMR precision thriving against humidity for seamless process control. The Triconex 3704E upholds GMP traceability, vital where analog variances void cultures. Across chemicals, energy, and biotech, the Triconex 3704E densifies analog trust, excelling where TMR tempers the tide of high-volume voltages.

Compatible or Alternative Products

Triconex 3703E – Standard TMR analog input module for lower-density (16-channel) voltage setups in space-constrained bays.

Triconex 3301 – Differential analog input variant with current focus for 4-20 mA-heavy loops.

Triconex 2301 – Baseplate for field termination of 3704E signals in Tricon chassis.

Triconex 3009 – Enhanced main processor for v10+ systems hosting 3704E in expanded TMR nodes.

Triconex 3805E – Analog output companion for closed-loop actuation from 3704E inputs.

Triconex 3700 – Legacy high-density AI for cost-sensitive upgrades from older Tricon systems.

Triconex 3706A – Thermocouple input module add-on for temperature extensions alongside 3704E.

Triconex 8310 – Chassis base for multi-slot 3704E arrays in redundant safety frames.

Setup Notes & Maintenance Insights

Before slotting the Triconex 3704E, confirm shunt configs—install 250 Ω for 5 V or 500 Ω for 10 V modes to match transmitter outputs, using 18-22 AWG shielded pairs grounded at the source to curb noise below 10 mV. Align in TMR bays with 0.8 Nm torque for TriBus seating, and validate isolation via megohmmeter at 500 V DC targeting >200 kΩ leg-to-leg, as humid cabinets can bridge commons in coastal plants. Pre-live, program channel groups in TriStation (default 8-point commons) and calibrate with a precision source to <0.25% FSR; offsets often arise from untorqued shunts, remedied at 0.5 Nm.

Sustained care meshes with SIS proofs, keeping voltages vigilant with audits that nip drifts sans full racks offline. Monthly, scan LEDs for group health—greens affirm activity, with faults cueing RS-232 pulls to log overranges, typically from loose terminals worth a retighten. Quarterly, sweep 0-10 V ramps across channels to benchmark resolution, archiving variances for shunt aging spots; this forestalls creeping inaccuracies before they skew loops. Biannually, in vibratory or dusty realms, inspect pins for corrosion with a loupe, applying grease to repel, and clean vents with ionized air to avert thermal throttling. Leverage Modbus trends monthly for rejection ratio checks, tying hums to nearby harmonics for shielding. These analog anchors, honed from bay battles, frame the Triconex 3704E as a set-sustain sentinel, diverting diligence to dynamic directives over dutiful drifts.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626