Description

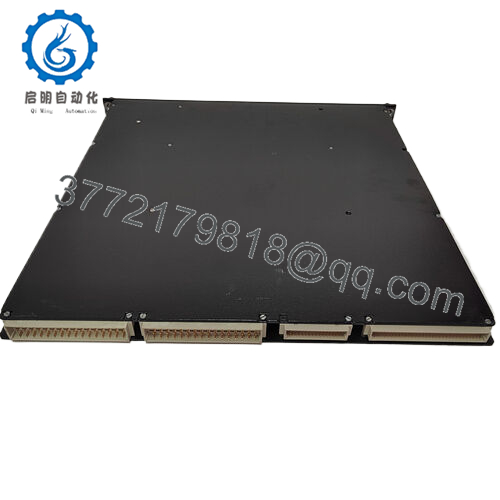

Product Model: Triconex 3700A

- Product Brand: Schneider Electric

- Product Series: Triconex Safety Instrumented System (SIS)

- Product Features:

- Triple modular redundant design for maximum reliability

- Certified for use in safety-critical industrial environments

- High compatibility with Triconex architecture

- Long-term operational stability with low maintenance needs

Applications & Industry Context

In industries where even a single system failure can mean enormous safety risks and financial loss, the Triconex 3700A is a trusted backbone of process safety. Think about environments like offshore oil rigs where corrosive salt air mixes with extreme pressure systems, or chemical refineries where volatile compounds demand continuous monitoring. In these places, downtime isn’t simply an inconvenience—it’s a direct threat to both human life and company assets.

This module is widely adopted in oil & gas, petrochemicals, nuclear energy, and large-scale power plants. In such settings, engineers rely on the Triconex 3700A to deliver redundant, fail-safe control that supports continuous operation even in the face of component degradation. Field anecdotes from refinery teams often note that having Triconex redundancy in place has allowed them to continue operations safely during hardware replacements, avoiding costly shutdowns. This balance between uninterrupted productivity and uncompromised safety is why operators consistently prefer the Triconex line for their Safety Instrumented Systems.

The reality of modern process industries is that automation isn’t just about efficiency; it’s also about regulatory compliance and liability. With global standards such as IEC 61508 and IEC 61511 shaping how safety is managed, the Triconex 3700A plays a vital role in meeting safety integrity level (SIL) requirements. It is not uncommon to see this controller cited in audit reports as a proven safeguard in high-risk operations, further reinforcing its reputation as an indispensable industrial component.

- 3700A

Technical Features & Benefits

One of the defining characteristics of the Triconex 3700A is its triple modular redundant (TMR) architecture. This means that three identical control pathways operate in parallel, constantly cross-checking one another. If one pathway encounters an issue, the other two seamlessly outvote it, ensuring that no incorrect signal is allowed to compromise plant safety. This design makes the module exceptionally robust against single points of failure.

From a performance perspective, engineers appreciate its ability to maintain deterministic response times even under high load. In high-speed process loops—such as emergency shutdowns or turbine protection systems—this speed and reliability mean the difference between a controlled stop and catastrophic equipment damage.

Another strong point is compatibility. The Triconex 3700A integrates naturally within Schneider Electric’s broader Triconex SIS ecosystem. This makes it easier for plant managers to scale or upgrade systems without needing to rip and replace entire architectures. Long lifecycle support, paired with firmware updates and backward compatibility, extends system viability across decades.

Beyond technical resilience, the module offers operational cost benefits. Because of its self-diagnostics and predictive failure detection, maintenance crews can plan interventions rather than react to unexpected outages. In practical terms, that means fewer unplanned shutdowns, lower spare part inventories, and smoother audits—all of which translate into tangible financial savings for industrial operators.

Technical Specifications

| Specification | Detail |

|---|---|

| Product Model | Triconex 3700A |

| Brand | Schneider Electric |

| Series | Triconex Safety Instrumented System (SIS) |

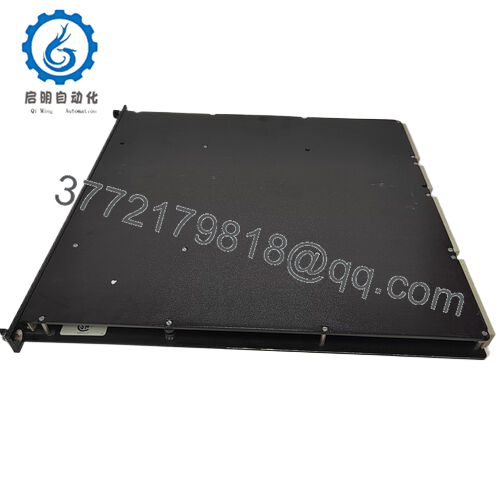

| Architecture | Triple Modular Redundant (TMR) |

| Function | Safety control and fault-tolerant module |

| Communication | Compatible with Tricon communication bus |

| Safety Certification | IEC 61508 / SIL3 compliant |

| Operating Temperature | -20°C to +60°C |

| Power Requirements | 24V DC nominal |

| Dimensions | Standard Triconex form factor |

| Typical Applications | Oil & Gas, Power Generation, Petrochemical, Nuclear |

| Maintenance Features | Self-diagnostics and fault isolation |

Product Role & System Fit

In a Triconex system, the Triconex 3700A functions as one of the cornerstone modules supporting the broader safety control strategy. Rather than acting as a standalone PLC, it is designed to be part of a redundant, distributed safety architecture. This role is especially critical in large facilities where multiple safety loops and protective layers must work in harmony.

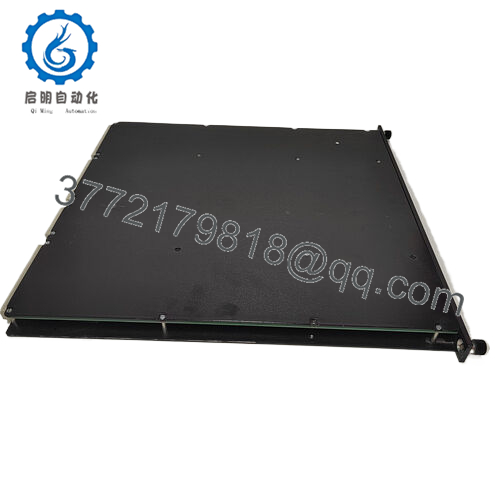

The 3700A fits directly into the Tricon chassis, aligning with input/output modules and communication interfaces. Its modularity ensures that system engineers can expand safety coverage without major redesigns. For example, adding another process unit in a refinery doesn’t require reinventing the safety backbone—just scale up with additional Triconex 3700A modules, and the architecture retains its high integrity.

Compatibility across generations of Triconex hardware means it can operate alongside both older and newer cards, which reduces system disruption during phased upgrades. This makes the 3700A an attractive option for operators who need to modernize incrementally while keeping legacy systems online.

Installation & Maintenance Insights

Installing the Triconex 3700A follows standard Triconex practices, but seasoned engineers often emphasize two practical tips. First, ensure that environmental conditions are well within specified ranges. While the module is rugged, long-term exposure to excessive vibration or heat will shorten its operational lifespan. Second, during insertion into the chassis, double-check that the alignment pins seat fully—improper seating can trigger diagnostic alarms.

Maintenance teams typically find the module easy to manage thanks to built-in diagnostics. The 3700A continuously reports health status, flagging potential degradation before it causes operational disruption. Field technicians often use these diagnostic signals to plan replacement schedules during routine turnarounds rather than waiting for unexpected trips.

Another helpful insight is to maintain spare 3700A modules in climate-controlled storage. Because of their role in critical safety systems, rapid replacement is often mandated by plant policies. Having spares readily available reduces downtime to mere minutes, which is especially valuable during regulatory inspections.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626