Description

The Triconex 3625 is primarily used in industrial automation applications where high-reliability digital output signals are essential for controlling safety-critical devices. Industries such as oil and gas, power generation, chemical processing, and transportation rely heavily on this module within their safety instrumented systems (SIS). The Triconex 3625 ensures that critical control signals—such as emergency shutdowns, valve actuations, alarm triggers, and motor controls—are delivered with maximum fault tolerance and integrity. It is tailored for applications demanding SIL 3 safety certification, where system redundancy and fail-safe operation guard against hazardous failures. In complex control environments, the Triconex 3625 provides the dependable interface between safety controllers and field devices, supporting remote site installations and extensive output point counts. Its use is prevalent in both new system builds and upgrades where maintaining uninterrupted safety control through robust digital outputs is paramount.

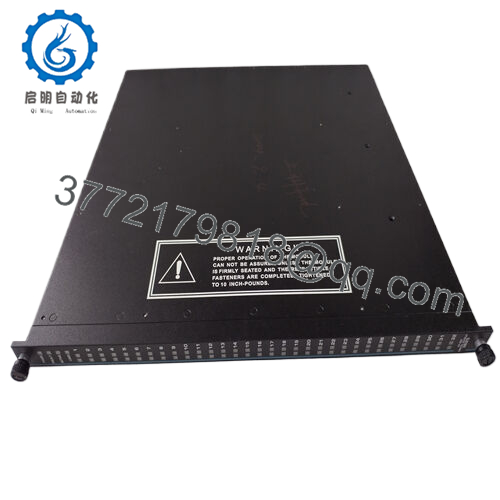

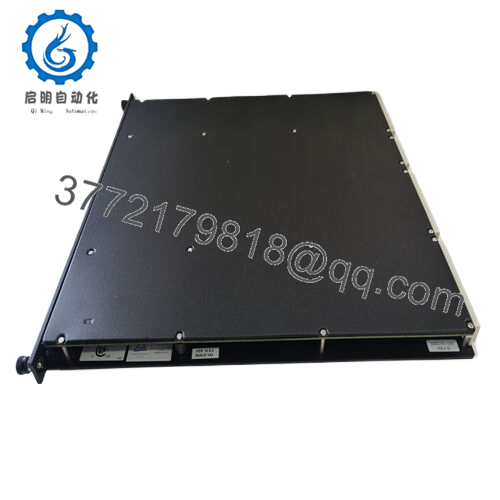

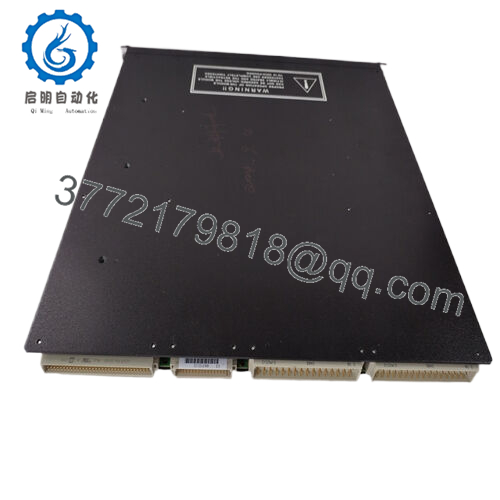

The Triconex 3625 is a digital output module designed for integration into Triconex Triple Modular Redundant (TMR) safety instrumented systems. Part of Schneider Electric’s Triconex family, it interfaces the safety processor system with final control elements such as contactors, solenoids, and indicator lights by generating controlled 24 VDC output signals. The module supports up to 32 output points that can be supervised or unsupervised, operating within a voltage range of 16 to 32 VDC and delivering up to 1.7 amps per point. It fits into the modular architecture by occupying standard rack spaces and communicates with Triconex processors to execute safety shutdown or fault response sequences. Its design aligns with stringent international safety standards, making it invaluable for engineering teams creating or maintaining certified safety shutdown loops and alarm actuation in hazardous process environments. Engineers appreciate the Triconex 3625 for its fault isolation capabilities and comprehensive diagnostics embedded within the module.

- 3625

Technically, the Triconex 3625 delivers superior functionality with its TMR architecture that ensures no single-point failure can compromise output signals. Each output channel includes three isolated circuits that vote on the correct output state, providing redundancy and error detection. The module features built-in current and voltage loopback circuits that continuously verify the status of output switches, cabling, and connected loads, enabling early detection of faults like open loads, shorts, or blown fuses without affecting the output state. Its typical voltage drop remains under 2.8 VDC at maximum current, supporting effective control of actuators and relays. The design supports hot-swapping, allowing maintenance activities without system shutdown. The module operates across an extended temperature range, from -40°C to +70°C, and meets IEC and NEMA IP67 ratings for protection against dust and moisture, suitable for harsh industrial conditions. Diagnostic indicators on the module provide clear status feedback for each point, including power, load, pass, fault, and active signals, aiding troubleshooting and reducing downtime. The compact dimensions and reasonable power consumption make it an efficient choice for large-scale control installations.

| Parameter | Value |

|---|---|

| Model | Triconex 3625 |

| Brand | Triconex (Schneider Electric) |

| Product Type | Digital Output Module |

| Number of Output Points | 32, general purpose |

| Output Voltage Range | 16 to 32 VDC |

| Maximum Output Voltage | 36 VDC |

| Current per Point (Max) | 1.7 Amps |

| Voltage Drop | < 2.8 VDC @ 1.7 A typical |

| Power Consumption | < 13 watts |

| Diagnostic Indicators | PASS, FAULT, LOAD, ACTIVE, POWER per point |

| Isolation | 1500 VDC |

| Operating Temperature | -40°C to +70°C |

| Mounting | Rack-mounted |

| Protection Rating | IEC IP67 |

| Certifications | SIL 3 (IEC 61508), UL, CSA |

| Weight | Approx. 1.2 kg |

| Dimensions | Approx. 24 cm x 12 cm x 5 cm |

The Triconex 3625 is often paired with related modules including:

Triconex 3601 – Processor module that governs safety logic managed by output modules like 3625.

Triconex 3623 – Smaller supervised digital output module with 16 points, for less extensive output needs.

Triconex 3721 – Analog input module processing sensor signals feeding control decisions output by 3625.

Triconex 4210 – Remote extender module that facilitates distributed deployment of output modules.

Triconex 4008 – Power supply module providing regulated power for the 3625 and other system components.

Installation of the Triconex 3625 requires planning for rack space allocation with adequate ventilation to maintain optimal temperatures. Proper grounding and shielding are essential to minimize electrical noise that could corrupt output signal integrity. Cabling should follow manufacturer recommendations to preserve diagnostic capabilities and fault detection performance. Maintenance includes routine inspection of LED diagnostic indicators for faults, verifying fault alarms through software diagnostics, and ensuring connectors and wiring remain secure and undamaged. Firmware and software updates should be applied during scheduled maintenance windows to ensure ongoing compatibility and functionality.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626