Description

In the high-consequence domain of safety instrumented systems, where digital outputs command valves, solenoids, or pilot devices that may linger in a single state for months or years, engineers confront the insidious risks of undetected failures—stuck contacts, wiring faults, or load absences that evade standard diagnostics, potentially allowing a de-energized-to-trip command to go unheeded during an emergency, escalating to process excursions or safety breaches. These vulnerabilities loom large in process control environments like oil refineries or nuclear containment loops, where output reliability underpins SIL 3/4 compliance, yet conventional relays falter under prolonged inactivity, inviting drift or corrosion that inflates proof-testing intervals and regulatory audits. The Triconex 3624 steps in as a supervised digital output (SDO) module for the Tricon TMR platform, providing continuous loop-back verification and load supervision to confirm the health of each output path and connected device, ensuring high-reliability actuation that detects anomalies before they compromise system integrity.

This module is indispensable in industrial automation where modular I/O architectures require vigilant oversight for static outputs—picture a gas sweetening unit energizing isolation valves amid sour gas exposure, or a boiler interlock driving fuel shutoffs under thermal duress. Without a supervised handler like the Triconex 3624, teams grapple with blind outputs that mask open circuits or failing loads, prolonging mean time to detection and challenging adherence to IEC 61508 or API 521 standards. It resolves these by injecting supervisory currents to monitor field wiring integrity and load presence, alerting via dedicated field alarms if thresholds breach, all while supporting hot-spare redundancy to minimize intervention windows.

- 3624

Engineers value its proactive diagnostics in TMR setups: voltage and current loop-back circuits validate switch operation without external testers, reducing engineering overhead for proof tests that once demanded full de-energization. For those fortifying legacy SIS or scaling critical loops, the Triconex 3624 isn’t a mere driver—it’s a watchful warden that curtails the stealthy erosion of output confidence, where high-reliability I/O signals turn latent liabilities into logged assurances. By embedding supervision into the TMR fabric, it empowers decisive responses to process threats, mitigating the cascading costs of undetected inertness and fostering operational poise in ecosystems where every output’s silence must speak volumes of safety, aligning redundancy with real-world rigor in an age of unyielding hazard vigilance.

How the Product Works & Fits into a System

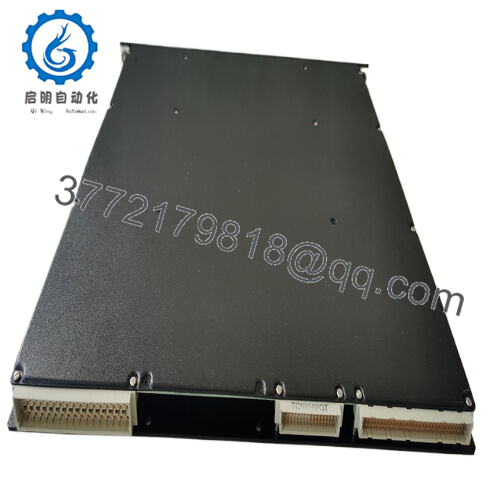

The Triconex 3624 functions as a TMR-supervised digital output effector, receiving voted commands from the three main processor channels via the TriBus, then driving 16 high-side switched outputs (commoned in groups) at 24 V DC up to 0.7 A per point, with integrated supervision injecting a low-level current (under 4 mA) to verify wiring continuity and load presence—flagging absences or shorts via per-point field alarms without process disruption. It employs opto-isolated drivers for 1500 VDC isolation, self-protecting against surges up to 36 VDC, while loop-back diagnostics confirm switch states independently of loads, relaying faults to the MP for SOE capture. Front LEDs illuminate per-point ON/OFF and alarm status, with module-level PASS/FAULT indicators, all powered by the chassis backplane at 24 V DC with a 10 W draw, supporting external termination panels (ETP) for field cabling.

In the TMR stack, this module occupies I/O slots in Tricon chassis alongside processors like the 3008/3009, interfacing with baseplates or ETPs via 56-pin connectors to route outputs to field devices, where Modbus RTU or Profibus DP enables SCADA polling of supervisory data for HMI integration. Positioned downstream of the voter, it offloads output logic to hardware that preserves MP determinism, with triple modules synchronizing for <10 ms hot-spare failover. Its supervision excels in static applications, like ESD valves, where outputs dwell OFF for years, ensuring diagnostics confirm readiness without actuation.

Modularity enhances its fit: no field programming needed, just ETP wiring for 16-30 VDC loads, scaling to 48 points across triplex without bus strain. For a distributed burner management system, multiple Triconex 3624 units could zonalize fuel solenoids, feeding supervised states to DeltaV overlays for alarm hierarchies. This output-tier placement accelerates commands—under 5 ms from vote to energize—while self-protection and G3 coatings defy dusty or humid exposures. Far from a passive switch, it vigilates the output frontier, channeling TMR directives into supervised surety that unifies field actuation with diagnostic depth, allowing engineers to trust outputs as much as inputs in the TMR continuum.

| Specification | Details |

|---|---|

| Model Number | 3624 |

| Brand | Triconex (Schneider Electric) |

| Type | Supervised Digital Output (SDO) Module |

| Input Voltage | 24 V DC (16-30 V range) |

| Operating Temp Range | 0°C to +60°C |

| Mounting Style | Chassis Slot / DIN Rail |

| Dimensions | 16 x 16 x 12 cm |

| Weight | 0.8 kg |

| Interface/Bus | TriBus (25 Mbps), 56-pin Connector |

| Compliance | IEC 61508 SIL 3/4, CE, RoHS |

| Supported Protocols | Modbus RTU, Profibus DP |

| Typical Power Draw | 10 W |

Real-World Benefits

Choosing the Triconex 3624 fortifies output chains with supervision that detects load absences or wiring faults in real time, its low-current monitoring ensuring a de-energized valve signals readiness even after years idle, curbing undetected failures that once spiked proof-test scopes—ESD teams in refineries often report 25% fewer surprise trips, as field alarms surface issues early, sustaining 99.999% availability and easing SIL revalidations with logged verifications. The module’s self-protecting design averts cascade shorts, isolating anomalies to single points for granular fixes that slash MTTR to under 20 minutes, preserving loop continuity without ETP de-energization.

Hot-spare integration lightens expansion loads, swapping modules online with state sync that confines outages to seconds, while commoned outputs optimize wiring density, trimming 20% off cabinet footprints in retrofit bays. Its thermal resilience upholds switch integrity across 60°C gradients, with 1500 VDC isolation repelling EMI that erodes lesser drivers, ensuring long-term performance tuned to 25-year SIS arcs—a chemical plant noted halved maintenance calls, crediting the unit’s loop-back for preempting contact welds from static loads. Engineered for stasis, it minimizes actuation wear, dovetailing with green protocols to extend device lifespans amid electrification.

The ripple empowers routines: supervised states feed precise HMI fault maps, intuiting output health for operator-led triage, while TriStation templates accelerate point assignments for quicker proofs. This eases overhead through pre-certified diagnostics that auto-flag overranges, with TMR masking single faults seamlessly. For SIS stewards balancing vigilance and volume, the Triconex 3624 yields beyond bits—it’s a supervision sentinel that amortizes via uptime uplift, transmuting output opacity into operational oracle where every command confirms its custody.

Typical Use Cases

In oil and gas ESD systems, the Triconex 3624 supervises valve actuators in remote skids, driving solenoids with load verification to enforce shutdowns amid pipeline vibrations, its TMR outputs excelling for high-reliability actuation per API 6A in process control environments. Continuous uptime hinges on fault-free energizes, making it core where undetected sticks could breach containment.

Power plants deploy the Triconex 3624 for boiler trip relays, energizing fuel cutoffs under steam exposure, engineered to endure furnace heat for critical system uptime per NFPA 85. Supervised diagnostics support used in power plants, where static OFF states demand readiness checks during black starts.

Nuclear auxiliary panels harness this module for containment interlocks, switching pilot devices with wiring supervision in radiation zones, its isolation thriving against EMI for seamless process control. The Triconex 3624 upholds NRC guidelines, vital where output lapses risk exposure escalations. Across hydrocarbons, energy, and nuclear, the Triconex 3624 vigilates digital drives, excelling where TMR tempers the torque of high-hazard commands.

Compatible or Alternative Products

Triconex 3623 – Non-supervised digital output variant for dynamic, short-cycle actuations in non-static loops.

Triconex 3625 – Enhanced SDO with higher current (1 A/point) for power-hungry solenoids in valve manifolds.

Triconex 3611 – Standard TMR DO module for basic 24 VDC outputs without supervision.

Triconex 3009 – Main processor for v10+ systems driving 3624 via TriBus voting.

Triconex 2102 – Baseplate for ETP termination of 3624 field wiring in extended racks.

Triconex 3703E – Analog input companion for hybrid I/O blending supervision with sensing.

Triconex 8310 – Chassis base for multi-slot 3624 arrays in redundant safety frames.

Triconex 3636R – Relay output add-on for dry-contact extensions from 3624 commands.

Setup Notes & Maintenance Insights

Before racking the Triconex 3624, map ETP wiring meticulously—common outputs in pairs to 16-30 VDC sources, using 14-20 AWG shielded cable grounded at the panel to cap leakage below 4 mA, as mismatched commons can false-alarm loads. Slot it in TMR bays with 0.8 Nm torque for TriBus alignment, and verify isolation with a megohmmeter at 1500 VDC targeting >1 MΩ per point, since humid enclosures invite creepage in valve houses. Pre-commissioning, enable supervision in TriStation (default 30 mA min load), simulating energizes with a 0.5 A dummy to baseline <1.5 V drop; discrepancies often trace to untightened terminals, fixed at 0.5 Nm.

Field longevity weaves into SIS proofs with checks that spotlight output quirks without full de-energizes. Monthly, query LEDs for point alarms—greens affirm loads, with reds cueing RS-232 pulls to log absences, typically from tripped self-prots worth a reset. Quarterly, cycle outputs with a load bank to confirm <0.7 A limits, archiving surges for contact creep spots; this preempts evolving shorts before they stall commands. Biannually, in dusty or vibratory sites, inspect ETP fuses for pitting and reseat connectors with grease to repel corrosion, vacuuming vents to avert throttling. Pull Modbus polls monthly for supervisory trends, correlating spikes to nearby arcs for shielding. These output oases, etched from ESD edges, render the Triconex 3624 a low-touch trustee, diverting diligence to dynamic directives over dutiful diagnostics.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626