Description

The Triconex 3604E is a trusted component in industrial automation systems where high-reliability digital outputs are critical to safety and process control. It is widely deployed in sectors such as petrochemical refining, power plants, oil and gas extraction, and large manufacturing facilities—environments that demand resilient fault-tolerant control architectures. In these settings, the Triconex 3604E provides dependable actuation signals to field devices like solenoids, relays, and contactors that perform emergency shutdowns, alarm activations, and process interlocks. Its presence helps industries comply with strict safety integrity level (SIL 3) standards, supporting mission-critical functions that prevent equipment damage, environmental hazards, and personnel risk. Companies rely on the Triconex 3604E in safety instrumented systems (SIS) because it integrates triple modular redundancy (TMR) to guarantee no single failure compromises output signal accuracy or availability. For engineers tasked with designing scalable and maintainable control systems, this module helps extend control reach across complex facilities with peace of mind that reliability and safety are not compromised.

- 3604E

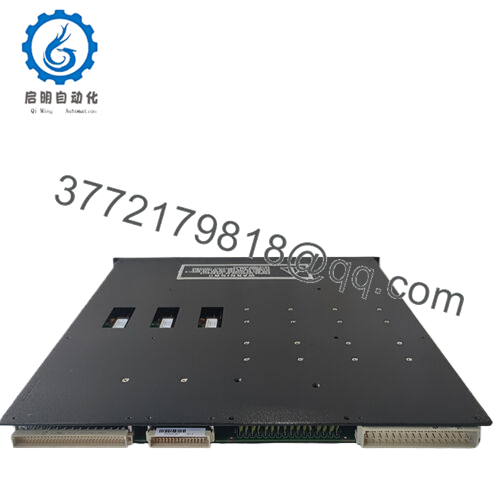

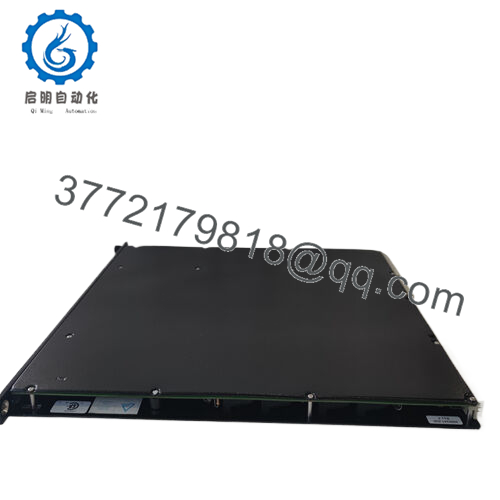

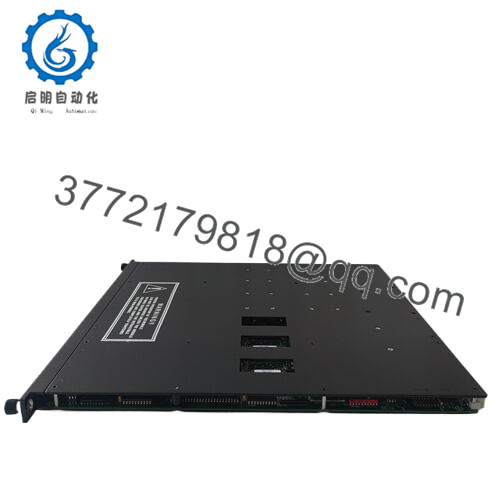

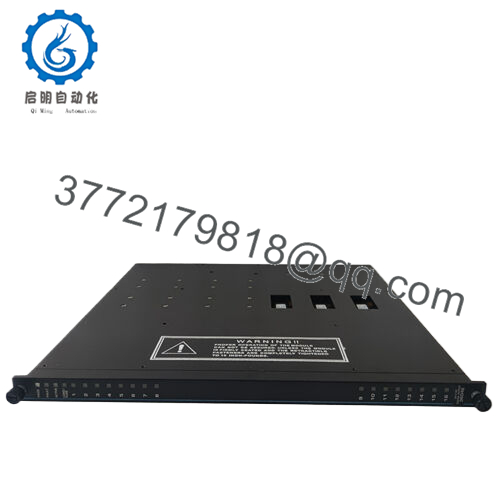

The Triconex 3604E is a TMR digital output module designed to interface directly with Triconex safety processor systems as part of a distributed control network. It operates as a critical final control element by providing 16 non-commoned digital output points capable of sourcing field power at nominal 24 VDC, with an operating voltage range between 22 and 45 VDC. This module is housed in a rack-mountable chassis, seamlessly fitting within the Triconex modular safety system architecture. By employing triple modular redundant voting circuits, the Triconex 3604E ensures that only valid, fault-checked signals are sent to the field, significantly minimizing risk of spurious or failed outputs. It supports hot-spare capability, allowing for hardware replacement or upgrades without system downtime, a key advantage in continuous operation environments. This module’s role as a reliable digital interface between process safety controls and actuators is highly valued for its diagnostic feedback capabilities and compliance with demanding industrial standards.

The Triconex 3604E boasts advanced features that reinforce its reputation for performance and durability. The triple modular redundancy architecture includes quadruplicate voter circuitry that cross-verifies the three processor output channels before generating a single output signal, ensuring maximum fault tolerance. Each output point contains loopback circuits that independently verify the functionality of the output switch and the presence of the correct load voltage, enabling early fault detection without interrupting output continuity. The module typically exhibits a voltage drop below 4 V at rated load, providing sufficient power for a wide range of final control elements. Designed to operate reliably within temperatures ranging from -40°C to +70°C, the 3604E tolerates harsh industrial conditions such as vibrations, humidity, and electrical noise. Diagnostic LEDs offer clear status for each output point covering load, fault, and active state indicators, simplifying maintenance and fault isolation. The device supports standard rack mounting with mechanically keyed installation to prevent misconfiguration, and its robust isolation design guards against electrical interference and ground loops. Overall, the Triconex 3604E balances compact form factor, efficient energy use, and comprehensive diagnostics to deliver a trustworthy digital output solution.

| Parameter | Value |

|---|---|

| Model | Triconex 3604E |

| Brand | Triconex (Schneider Electric) |

| Product Type | TMR Digital Output Module |

| Number of Output Points | 16 non-commoned |

| Nominal Voltage | 24 VDC |

| Operating Voltage Range | 22 to 45 VDC |

| Voltage Drop | Less than 4 V at rated load |

| Current per Point | Up to 2 A |

| Power Consumption | Approximately 15 watts |

| Operating Temperature | -40°C to +70°C |

| Protection Rating | IEC IP30 (typical rack environment) |

| Mounting | Standard rack mount |

| Diagnostic Indicators | Load, Fault, Active LEDs for each output channel |

| Isolation | >1500 VAC isolation between channels |

| Certifications | SIL 3 (IEC 61508), UL, CE |

| Weight | Approx. 0.8 kg |

| Dimensions | Approx. 16 cm x 16 cm x 12 cm |

The Triconex 3604E complements other Triconex modules such as:

Triconex 3601E – Digital output module with different voltage specifications.

Triconex 3625 – Digital output module offering 32 output points for higher density needs.

Triconex 3721 – Analog input module providing sensor data to digital output modules.

Triconex 4210 – Remote extender module allowing expansion of I/O across large facilities.

Triconex 4008 – A reliable power supply module for supporting the entire Triconex control system.

Installation guidance for the Triconex 3604E includes verifying sufficient rack space and adhering to grounding principles to reduce electrical noise and ensure signal fidelity. Proper ventilation in the control cabinet prevents thermal stress, optimizing performance and lifespan. Maintenance routines should emphasize frequent monitoring of status LEDs to detect early faults and routine validation through system diagnostics software. Firmware updates should be coordinated with control system downtime planning to maintain operational integrity. Connectors and cabling must be regularly inspected and cleaned to avoid connectivity issues that could undermine fault detection.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626