Description

TRICONEX 3504E is a high-performance, safety critical controller module. It is an indispensable part of the TRICONEX security system, which has always been renowned for unparalleled reliability in protecting industrial processes.

3504E

Functionally speaking, 3504E serves as the nerve center of the safety instrumented system. It interfaces with various on-site sensors, including pressure sensors, temperature sensors, and flame detectors, to collect real-time data from industrial processes. By utilizing its advanced processing capabilities, it is able to analyze this data at high speed and make critical decisions. Based on these decisions, it will send control signals to actuators such as emergency stop valves, motor starters, and other safety related equipment. In the architecture of the safety instrumented control system, 3504E occupies the core and coordinating position, ensuring that all components work together to ensure the safety of the entire industrial process.

3504E

Main features and advantages:

In terms of performance, it provides extremely fast data processing capabilities. It can execute complex control algorithms and analyze large amounts of sensor data within a few milliseconds. This high-speed processing capability is crucial for high-speed industrial processes, such as high-throughput chemical production lines, where decision delays can lead to catastrophic consequences.

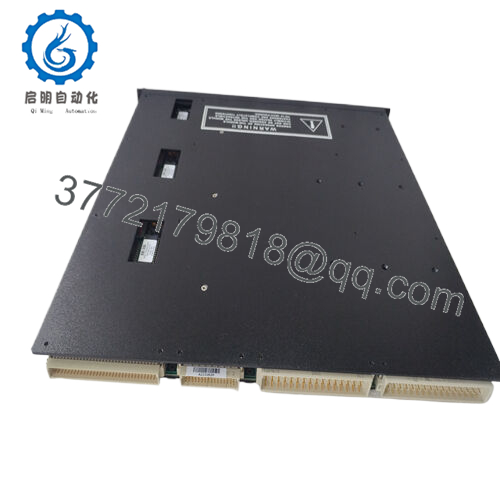

The hardware structure of 3504E is sturdy and can withstand the harshest industrial environments. It has high resistance to vibration, can operate in the extreme temperature range of -40 ° C to 85 ° C, and can resist electromagnetic interference. This durability ensures that it can operate reliably in challenging environments, such as offshore oil drilling platforms, where equipment is exposed to harsh sea conditions, strong winds, and powerful electromagnetic fields from nearby power generation and communication systems.

Compatibility is a prominent advantage of 3504E . It supports multiple industry standard communication protocols, including Profibus and Modbus. This enables it to seamlessly integrate with other devices in the control system, whether they come from Triconex or other manufacturers. It also facilitates the expansion of safety systems when adding processes or equipment in industrial factories, providing long-term scalability.

In terms of long-term reliability, the3504E adopts redundant design elements. The redundant design of key components such as processors and power supplies ensures that if one part fails, the module can still operate continuously. This significantly reduces the risk of system failures and related shutdowns, giving industrial operators peace of mind and reducing costs incurred due to production losses.

3504E

Technical specifications:

Model 3504E

Brand Triconex

Type Safety Critical Controller Module

Power supply 24 VDC

Working temperature -40 ° C to 85 ° C

Installation method: DIN rail installation

Size 140 x 220 x 90 millimeters

Weight 0.8 kilograms

Interface Profibus, Modbus, Analog Input/Output, Digital Input/Output

Certified IEC 61508 SIL 3, UL, CE

Natural convection method for heat dissipation

Protection level IP20

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

3504E

Application areas:

In the oil and gas industry, refineries are busy places where various processes operate simultaneously. The TRICONEX3504E plays a critical role in Safety Instrumented Systems (SIS). For example, in the crude oil distillation unit of a large refinery, it continuously monitors key parameters. It will closely monitor the temperature of the distillation tower to ensure it remains within the optimal range for efficient separation of different hydrocarbon components. Any temperature deviation can lead to a decrease in product quality and even cause equipment damage. In addition, it also monitors the pressure of pipelines transporting highly flammable hydrocarbon substances. If the pressure suddenly surges, it may indicate that the pipeline is blocked or the valve is malfunctioning, and the 3504E can detect this situation in real time. Subsequently, it will immediately initiate an emergency shutdown procedure, close the safety valve to isolate the affected area, and prevent possible explosions or large-scale leaks, which may have serious impacts on the environment and safety.

Chemical companies, with their complex reaction processes, also heavily rely on TriconeX 3504E. In a petrochemical plant that produces polymers, precise control of temperature and pressure is required during the polymerization reaction process. 3504E receives data from numerous sensors scattered throughout the reactor and related equipment. If the temperature starts to exceed the safe operating range, it may cause uncontrollable reactions that endanger the safety of the factory and workers. At this point, the equipment can take immediate corrective measures. It may adjust the cooling system, change the flow rate of reactants, or even completely stop the reaction to ensure operational safety.

Power generation facilities, whether coal-fired, nuclear, or gas turbine power, rely on 3504E to maintain stable and safe electricity production. In a nuclear power plant, it monitors key variables such as reactor coolant level, radiation level, and the integrity of the containment structure. 3504E will quickly handle any abnormal readings for immediate response. In gas-fired power plants, it optimizes the combustion process to ensure efficient mixing of fuel and air to achieve maximum power generation while strictly adhering to safety standards. Its fast, accurate, and reliable control capabilities in these industrial automation and control systems make it an important component in ensuring operations and preventing disasters.

3504E

Related products:

Triconex 3504E-HC – suitable for applications that require a large number of I/O points, such as complex petrochemical plants or large power generation facilities.

Triconex 3504E-XT – designed to operate in more extreme temperature ranges, suitable for installation in extreme environments such as the Arctic or desert oil fields.

Triconex 3504E-RP – With redundant power inputs, it provides enhanced reliability for critical systems that cannot tolerate power failures, such as life critical safety systems.

Triconex 3504E-ADV – Provides more advanced diagnostic capabilities for in-depth analysis of system health in complex automation settings, such as those found in modern smart factories.

Triconex 3504E-LP – optimized for low power consumption, reducing the overall energy consumption of the system, which is very beneficial for applications that focus on energy efficiency, such as certain renewable energy facilities.

Installation and maintenance:

Before installing the Triconex 3504E, it is essential to verify its compatibility with your existing Triconex system. Check if there are available slots on the backplane and ensure that the firmware for the control platform is up-to-date. This ensures seamless integration and prevents potential compatibility issues. In addition, it is necessary to evaluate the available space to ensure proper ventilation, as modules generate heat during operation and sufficient cooling is crucial for optimal performance.

For continuous maintenance, please regularly check the LED status indicator lights on the module. These indicator lights provide quick visual cues of the module’s operational status, allowing you to promptly detect any abnormal situations. Regularly inspect connectors to ensure they are clean and secure, as loose or corroded connections may cause signal loss or interference. It is also recommended to conduct a functional test once a year to confirm the performance of the module and detect any early signs of degradation.

Other product models of Triconex:

TRICONEX 8111

TRICONEX 4351B

TRICONEX 3008

TRICONEX 3625C1

TRICONEX 3503E

TRICONEX 3700A

TRICONEX 3625

TRICONEX 4200

TRICONEX RXM4200-3

TRICONEX 8310

TRICONEX 3626X

TRICONEX MP3101S2

TRICONEX PLM3900N

TRICONEX 8310

Triconex IMFF4703x

TRICONEX 3351S2

Triconex 3603E

Triconex Mar-01

TRICONEX 3401S

TRICONEX 3401S2

TRICONEX 3009

TRICONEX RXM4201

Triconex 3501T

TRICONEX 3503E

TRICONEX 3503E

TRICONEX 3504Е

Triconex 3604E

TRICONEX 3623T

Triconex 3636R

TRICONEX 3704E

TRICONEX 3704Е

TRICONEX 3723X

TRICONEX 3805E

TRICONEX 3805E

TRICONEX 3805E

Triconex 3805E

Triconex 3806E

TRICONEX 8310N2

Triconex 4210

Triconex 4211

TRICONEX 9566-810

TRICONEX 3351S2

TRICONEX 3511

TRICONEX 3664

TRICONEX 3625C1

TRICONEX 3008

Triconex 3607E

TRICONEX 3604E

TRICONEX 3009

TRICONEX 3624

TRICONEX RXM4201

TRICONEX 8310

TRICONEX 4351B

TRICONEX 4351B

TRICONEX 4351B

TRICONEX CIM3211S2

TRICONEX DI3301S2

TRICONEX A03481S2

TRICONEX 3805H

TRICONEX 3506X

TRICONEX 3626X

TRICONEX 4355X

TRICONEX 7400247-020

Triconex 8311

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626