Description

Real-World Use & Application Scenarios

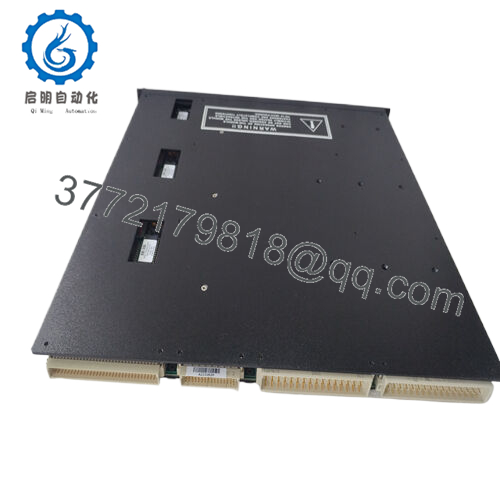

The TRICONEX 3504E digital input module is an essential component in safety-critical industrial environments such as petrochemical plants, power generation facilities, and chemical processing industries. Its main function is to acquire discrete digital input signals from sensors, switches, and field devices, ensuring accurate and reliable data transfer to safety controllers for emergency shutdown and process safety systems.

Widely used in triple modular redundancy (TMR) configurations, this module provides fault-tolerant operation and SIL 3 safety integrity, crucial in applications where human safety and equipment protection are mandatory. The 3504E supports real-time monitoring of emergency stop circuits, safety interlocks, and process alarms, delivering dependable performance in harsh and demanding environments.

This digital input module is indispensable for systems requiring high input density, fast response, and continuous fault diagnostics.

Product Introduction & Positioning

The TRICONEX 3504E is a high-density digital input baseplate module featuring 64 discrete input points, grouped in sets of 8 for efficient wiring and diagnostic segregation. The module is designed for integration into Triconex’s TMR safety systems to provide extensive input capability with full diagnostic coverage.

- 3504E

It operates with standard 24 or 48 VDC input voltages, supporting a broad input frequency range including DC and line frequency signals. The input circuitry incorporates channel isolation and advanced fault-detection capabilities, supporting safe system operation.

Positioned as a high reliability, high availability input module within ABB’s safety instrumentation portfolio, the 3504E is commonly paired with Triconex processors and output modules to build comprehensive safety instrumented systems.

Key Technical Features & Functional Benefits

The 3504E module offers 64 isolated digital input channels with triple modular redundancy, providing continuous verification of channel statuses. The module supports software-configurable input voltage levels to suit varied industrial signal standards.

High diagnostic coverage (>99%) includes detection of “stuck on/off” conditions and channel faults within half a second, enabling swift fault management and maintenance scheduling. The module supports hot-swapping in TMR systems, allowing replacement without process interruption.

Robust operating temperature range (-40 to +70°C) and industrial-grade ruggedness suit it for extreme environments such as offshore platforms and refineries. Its modular design simplifies system expansion and maintenance.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | TRICONEX 3504E |

| Manufacturer | Triconex (ABB) |

| Product Type | High-Density Digital Input Module |

| Number of Input Points | 64 (Groupings of 8) |

| Input Voltage | 24 or 48 V DC (configurable) |

| Input Frequency | DC or 47.63 Hz |

| Diagnostic Coverage | >99% |

| Response Time | < 0.5 seconds (self-test) |

| Operating Temperature Range | -40°C to +70°C |

| Isolation | Channel-to-channel isolation |

| Safety Integrity Level | SIL 3 Certified |

| Dimensions | Typical Triconex module size |

Related Modules or Compatible Units

TRICONEX 2401 – Digital output module complementing 3504E inputs for complete control.

TRICONEX 3009 – Main processor module managing safety logic operations.

TRICONEX BC800 – Bus communication and interface module for Triconex systems.

TRICONEX 3505 – Analog input module extending sensor signal acquisition.

TRICONEX 3603 – Digital output module for actuation and control signal generation.

Installation Notes & Maintenance Best Practices

Install the 3504E module in certified control cabinets following ABB Triconex installation standards. Ensure secure mounting, proper grounding, and shield field wiring to minimize noise and ensure signal integrity.

Routine maintenance should include verifying LED fault indicators, conducting system diagnostics through Triconex software toolsets, and performing periodic firmware updates. The module’s hot-swap capability facilitates field replacement without downtime to critical safety systems.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626