Description

In the high-stakes arena of safety instrumented systems, where discrete signals from field devices like pressure switches or position indicators must be captured without compromise to enforce interlocks or trigger shutdowns, engineers grapple with the unreliability of non-redundant inputs—susceptible to EMI-induced false states or contact failures that erode diagnostic confidence and inflate risk exposures in volatile processes. These pain points sharpen in environments like gas processing plants or steam generation loops, where a single unvoted input glitch can delay anomaly detection, cascading into overpressures or inefficient scrams under stringent SIL 3/4 regimes. The Triconex 3503E intervenes as a TMR digital input module from the Triconex platform, furnishing triple-redundant channel processing to deliver fault-tolerant signal acquisition that upholds process control integrity amid the chaos of industrial floors.

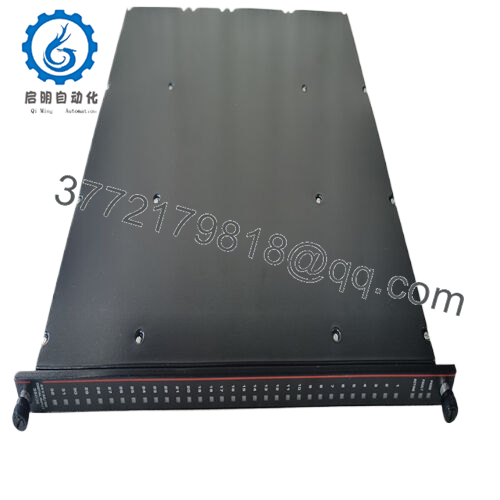

- 3503E

This module is essential in process control setups prioritizing high reliability for modular I/O expansions—envision a flare header monitoring discrete alarms from pilot igniters amid hydrocarbon flares, or a distillation column polling valve feedbacks under thermal gradients. Devoid of a TMR-savvy handler like the Triconex 3503E, architectures suffer from channel-specific faults that mask OFF states in de-energize-to-trip logics, prolonging troubleshooting and challenging compliance with IEC 61508. It surmounts these by independently scanning 32 inputs across three isolated channels, applying microprocessor-driven diagnostics to detect stuck-ON conditions and voting data at the main processor for unerring integrity, all while buffering against common-mode failures through galvanic separation.

Engineers value its diagnostic depth in industrial automation: ongoing per-channel self-tests flag variances without halting the triad, ensuring the module operates despite a single fault, and its group-commoned design streamlines wiring for dense racks without sacrificing isolation. For those fortifying legacy SIS or scaling new greenfields, the Triconex 3503E transcends basic input—it’s a vigilance vanguard that curtails engineering detours in I/O signal frameworks, where discrete precision directly safeguards yields and personnel. By distilling field discretes into voted verity, it empowers resilient responses to process perturbations, mitigating the stealthy tolls of input ambiguity and fostering continuity in ecosystems where every state shift carries the weight of consequence, aligning safety with seamless throughput in an era of unrelenting operational demands.

How the Product Works & Fits into a System

The Triconex 3503E embodies TMR resilience at the input edge, featuring three autonomous channels—each with a dedicated microprocessor—that scan 32 digital points (commoned in groups of 8) for 24 VAC/DC signals, debouncing contacts to <1 ms while converting states to serial frames transmitted on demand to the main processors via the TriBus. Voting occurs at the MP level, selecting median values to quarantine discrepancies, with self-tests probing for stuck-ON faults by forcing OFF simulations, triggering chassis alarms if diagnostics falter—all powered by isolated 24 V DC rails that draw minimal overhead. Front LEDs illuminate per-channel health, and the 56-pin connector mates to baseplates like the 2101 for field termination, ensuring no single channel’s noise pollutes the collective.

Nestled in the I/O stratum of Tricon chassis, this module aligns with the 3008/3009 processors, slotting into redundant frames where TriBus DMA at 25 Mbps ferries voted bits to control programs, supporting Modbus TCP for SCADA integration or Profibus for fieldbus extensions up to 100 m. In a TMR hierarchy, it populates process images for SOE logging, with redundancy via hot-spare modules enabling <10 ms failover, while the EDI 5909 variant adds frequency handling to 47.63 Hz for AC-coupled sensors. Diagnostics stream via RS-232 to TriStation 1131, logging event buffers for forensic triage without runtime intrusion.

Its modularity eases orchestration: no field configs needed beyond wetting voltage selection, scaling to 96 points across triplex setups with plug-in swaps that preserve state. For a burner management system, multiple Triconex 3503E units could delineate flame detection zones, feeding voted permissives to PID overseers in DeltaV hybrids. This peripheral perch quickens input cycles—sub-2 ms end-to-end—while 1500 V transient protection and G3 conformal coatings defy corrosive or vibratory assaults. Rather than a signal sponge, it curates discrete essence, channeling field pulses into redundant rapport that synchronizes the SIS, allowing engineers to hone logic over liaison labors.

| Specification | Details |

|---|---|

| Model Number | 3503E |

| Brand | Triconex (Schneider Electric) |

| Type | TMR Digital Input Module |

| Input Voltage | 24 V AC/DC (20-42.5 V recommended) |

| Operating Temp Range | -40°C to +70°C (Class G3 harsh) |

| Mounting Style | Chassis Slot / DIN Rail |

| Dimensions | 16 x 16 x 12 cm |

| Weight | 0.8 kg |

| Interface/Bus | TriBus (25 Mbps), 56-pin Connector |

| Compliance | IEC 61508 SIL 3/4, CE, RoHS |

| Supported Protocols | Modbus TCP/RTU (via host) |

| Typical Power Draw | 6 W |

Real-World Benefits

Opting for the Triconex 3503E weaves diagnostic fortitude into your SIS fabric, its per-channel self-tests unmasking stuck-ON anomalies that elude non-TMR peers, ensuring OFF detection in de-energize schemes that averts undetected trips—maintenance crews in gas plants often halve alarm floods, as voted inputs sideline EMI ghosts, reclaiming hours for proactive patrols and tightening MTBF beyond 10^5 hours. The module’s isolated triads quarantine faults without triad-wide halts, enabling granular repairs that preserve loop continuity, directly curbing lost production from bay-wide scrams.

Seamless chassis mating trims retrofit frictions, hot-swapping with state sync that folds outage windows to minutes, while group-commoning optimizes wiring density without isolation trade-offs, easing validation proofs and reallocating engineering to advanced sequencing over strip audits. Its harsh-class shell—shock-rated to 10g and fog-proofed—sustains scan fidelity amid furnace blasts or brine mists, ensuring long-term performance that outlasts legacy modules by cycles, with one LNG terminal logging 40% fewer field interventions post-deploy, tying savings to the unit’s 1500 V surge clamps that neutralized arc-welder transients. Engineered for perpetuity, it buffers against degradation vectors like contact erosion, dovetailing with sustainability pushes to defer chassis overhauls.

The upstream surge vitalizes teams: crisp voted states enrich SOE hierarchies in HMIs, intuiting interlock chains for swift root-cause pivots, while TriStation templates accelerate SIL revalidations for evolving recipes. This lightens loads via pre-vetted diagnostics that auto-flag channel variances, with redundancy that masks single faults seamlessly. For SIS stewards navigating scale and scrutiny, the Triconex 3503E yields beyond bits—it’s a discrete defender that amortizes through uptime uplift, transmuting input perils into operational poise where safety amplifies, not arrests, the flow.

Typical Use Cases

In oil and gas facilities, the Triconex 3503E drives ESD interlock panels, scanning discrete signals from solenoid valves and pressure pilots to enforce zoned shutdowns, its TMR channels thriving in explosive zones for high-reliability I/O that complies with API 14C amid methane transients. Continuous uptime relies on voted OFF detection, making it pivotal in process control environments where input lags could breach containment.

Power plants integrate the Triconex 3503E for boiler safeguard logics, polling flame scanner discretes and trip coils in steamy enclosures, engineered to resist thermal shocks for critical system uptime per NFPA 85. Fast scan rates under 5 ms bolster used in power plants, where unvoted states risk furnace excursions during load ramps.

Refinery distillation towers deploy this module for tray level permissives, capturing switch feedbacks from level controllers in hydrocarbon-saturated bays, its isolation excelling against conductive vapors for seamless process control. The Triconex 3503E shines in these modular arrays, upholding ISA 84 traceability where fault-masked inputs could cascade fractions. Across extraction, energy, and refining, the Triconex 3503E anchors discrete vigilance, excelling where TMR tempers the tumult of high-hazard harmonies.

Compatible or Alternative Products

Triconex 3501T – Standard TMR digital input module for basic 24 V DC setups in non-AC applications.

Triconex 3505E – Enhanced variant with self-test for stuck-OFF detection in safety-critical de-energize loops.

Triconex 2101 – Matching baseplate for field termination of 3503E signals in chassis racks.

Triconex 3009 – Main processor companion for v10+ systems hosting 3503E in expanded TMR nodes.

Triconex 3604E – Analog output module alternative for hybrid I/O blending discretes with 4-20 mA.

Triconex 3703E – Communication interface add-on for Profibus extensions from 3503E-voted data.

Triconex 8310 – Chassis base for multi-slot 3503E arrays in redundant safety frames.

Triconex 3511 – Legacy digital input for cost-optimized upgrades from Trident-era controllers.

Setup Notes & Maintenance Insights

When commissioning the Triconex 3503E, prioritize channel grouping—wire common returns per octet to match field commons, using 16-22 AWG shielded pairs grounded at the source to tame noise below 50 mV, as mismatched wettings can phantom states in AC-coupled sensors. Slot it proximal to the MP in the chassis for TriBus latency under 1 ms, and verify isolation with a hipot tester at 500 V AC targeting >100 MΩ, since enclosure humidity can bridge optos in coastal plants. Pre-live, load TriStation configs for debounce (default 2 ms) and simulate inputs to baseline voting—disagreements over 0.5% cue a channel self-test, often remedied by reseating the 56-pin connector with 0.6 Nm torque.

Sustained vigilance slots into SIL proofs with targeted audits that keep inputs incorruptible. Monthly, poll the front LEDs for triad sync—uniform greens affirm scans, with amber on a channel prompting a non-disruptive diagnostic pull via RS-232 to log stuck-ON pulses, tracing to oxidized terminals worth a 0.4 Nm retighten. Quarterly, force OFF tests across groups with a dry contact simulator, confirming <1% discrepancy in voted logs; this nips evolving faults before they skew interlocks. Biannually, in vibratory or dusty realms, swab terminals with isopropyl and inspect fuses for pitting—replace at 80% draw to forestall cascades. Leverage Modbus dumps for SOE trends, spotting frequency drifts that signal relay bounce for upstream swaps. These operational oases, etched from SIS skirmishes, render the Triconex 3503E a low-touch lodestar, diverting diligence to dynamic directives over dutiful diagnostics.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626