Description

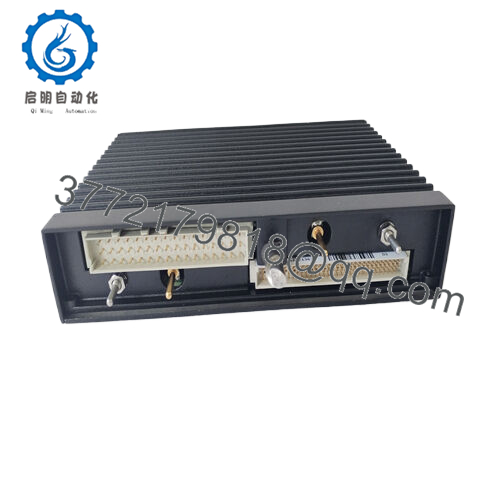

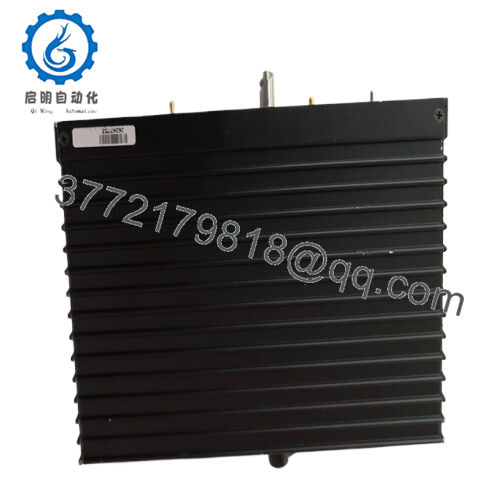

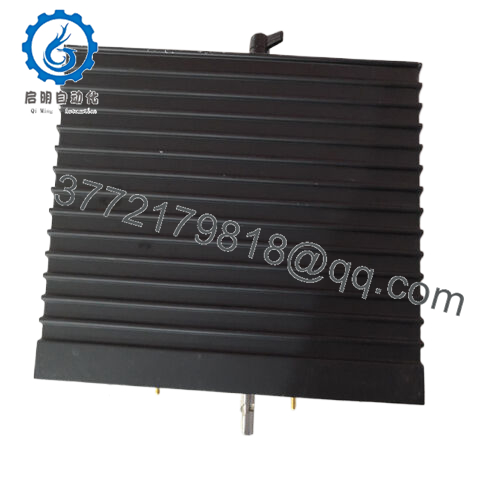

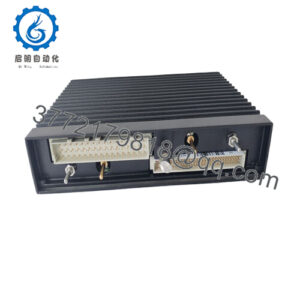

TRICONEX 3451 is a high-performance digital output module designed to meet the strict requirements of industrial automation and safety instrumented systems. As a member of the well-known TRICONEX product line, it focuses on reliability, accuracy, and compatibility. This module is a key link between the digital commands of the control system and the external devices that execute these commands on the industrial site.

3451

In the architecture of industrial control systems, TRICONEX3451 occupies a core position. It is directly connected to the safety controller or programmable logic controller (PLC). The control system sends digital signals, such as on/off commands, to TriconeX 3451. Then, the module converts these signals into physical outputs to drive various external devices, including valves, relays, and motors. Its design is easy to integrate into existing control system frameworks, whether it is large industrial complexes with hundreds of interconnected devices or small specialized factories with only a few key control points.

3451

Main features and advantages:

In safety critical applications, every millisecond is crucial, and this module can quickly convert digital input signals into output actions. Its ultra fast response time is less than 1 millisecond, ensuring that commands from the control system can be executed immediately. For example, in petrochemical plants, when a safety related event occurs, such as a sudden increase in temperature that may cause chemical reactions to spiral out of control, the TRICONEX 3451 can quickly activate the emergency cooling system. This immediate response helps prevent potential disasters and reduce the impact on factory operations.

The TRICONEX 3451 also has advanced diagnostic capabilities. It continuously monitors the integrity of its internal components and output signals. If any abnormal situation is detected, such as output channel short circuit or module power loss, it will quickly issue an alarm. This proactive diagnostic method can detect problems in advance and reduce the likelihood of system failures. In industrial environments, unplanned downtime costs are extremely high, and these diagnostic functions are very valuable. They enable the maintenance team to handle issues before they escalate, ensuring the continuous and reliable operation of the control system.

In terms of hardware design, the TRICONEX 3451 is sturdy and durable, capable of withstanding the harshest industrial environments. Its sturdy structure can prevent vibration effects, which are more common in industrial environments due to the operation of heavy machinery. It also has the ability to resist electromagnetic interference, which may interfere with the normal operation of electronic components. This module can operate within a wide temperature range of -40 ° C to+70 ° C and is suitable for extreme climate regions or industrial processes that generate high temperatures.

Compatibility is another major advantage of TRICONEX 3451 . It supports multiple communication protocols, including Modbus RTU. This means that it can be easily integrated with different types of control systems and other industrial equipment. Whether it is a traditional control system using older communication standards or an advanced system using the latest protocol, TRICONEX3451 can achieve effective communication, promote seamless data transmission and control. In the long run, the TRICONEX 3451 has excellent reliability. Its redundant design, equipped with multiple independent channels, ensures that even if one channel fails, the module can continue to operate. This high reliability is crucial in applications that require continuous operation without compromise, such as the control of critical industrial processes.

Technical specifications:

Model 3451

Brand Triconex

Type digital output module

Nominal output voltage 24 V DC

Working voltage range 15-30 V DC

Absolute maximum output voltage 33 V DC

Absolute maximum reverse input voltage -0.6 V DC

Switching current (self limiting)<4.8 A

Switching current (typical value) 3.0 A

Degraded mode current (self limiting)>0.7 A

Degraded mode current (typical value) 1.5 A

On site alarm for “loss of power supply” and “short circuit at output point”

Load leakage (off) can be measured

Multiple output channels (depending on configuration)

Output signal types: dry contact signal, DC voltage signal, AC voltage signal

Communication Protocol Modbus RTU

Certified UL, CE, CSA, TUV

Working temperature -40 ° C to+70 ° C

Installation method: DIN rail installation

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

3451

Application areas:

In the oil and gas industry, there are numerous potential hazards, and the TRICONEX3451 is a core component in safety critical operations. Taking offshore oil drilling platforms as an example, highly flammable crude oil and natural gas are extracted and transported here. TRICONEX 3451 is deployed to control complex valve and pump networks. Once an emergency situation occurs, such as gas leakage or abnormal pressure surge, it will quickly receive signals from sensors and safety control systems. Based on these input signals, it will immediately activate the corresponding valves, cut off the flow of hydrocarbons, and prevent catastrophic explosions and environmental disasters from occurring. This not only ensures the safety of drilling platform workers, but also protects the huge investment in infrastructure.

Chemical factories handle a large amount of highly reactive and often dangerous substances, heavily relying on TRICONEX 3451. For example, in a large chemical manufacturing plant that produces fertilizers, this module is used to control the motors that drive the mixing and conveying equipment. Accurate control of these motors is crucial for ensuring accurate mixing of raw materials, which directly affects the quality of the final product. TRICONEX 3451 ensures that the motor starts, stops, and runs at the correct speed according to the requirements of the process control system, which contributes to the efficient and safe production of fertilizers.

Whether it is coal-fired, nuclear, or renewable energy power plants, they can all benefit from the functionality of TRICONEX3451. In coal-fired power plants, it can be used as a relay to control the electrical circuit of the generator. When the demand for electricity fluctuates, the control system sends a signal to TriconeX 3451, which then activates the relay to adjust the output of the generator. This seamless control helps maintain stable power supply to the grid, reduce the risk of power outages, and ensure the reliable operation of power generation infrastructure.

3451

Related products:

TRICONEX 3503E – an I/O module that can be used in conjunction with TRICONEX 3451 to expand the overall I/O capabilities of the control system. It provides additional input and output channels, enabling more comprehensive monitoring and control of industrial processes. For example, in large manufacturing plants, the TRICONEX 3503E and TRICONEX 3451 can be added to the system together to handle more sensors and actuators, achieving finer process control.

TRICONEX 3805E – Communication module that enhances the connectivity of TRICONEX 3451. By integrating with this module, TRICONEX 3451 is able to communicate more effectively with other components in the control network, such as remote sensors and actuators. This improves the overall communication efficiency within the system. In distributed industrial facilities, TRICONEX 3805E helps TRICONEX 3451 connect sensors and actuators located in different areas, ensuring seamless data transmission and control.

TRICONEX 4351B – Redundant Controller Module. In applications that require extremely high system redundancy, the TRICONEX 3451 can be used in conjunction with the TRICONEX 4351B. This combination ensures continuous operation even in the event of controller failure. For example, in a nuclear power plant, the redundancy provided by TRICONEX 4351B and the reliable output function of TRICONEX 3451 work together to ensure the safety of critical control systems.

TRICONEX 1781- Power module designed to provide stable and reliable power to TRICONEX 3451 and other devices connected in the control system. A stable power supply is crucial for the normal operation of the TRICONEX 3451, and the TRICONEX 1781 can meet its power requirements. In industrial environments where power fluctuations may occur, the TRICONEX 1781 helps maintain stable operation of the TRICONEX 3451.

TRICONEX 1771- IBD – Interface module that simplifies the connection between TRICONEX 3451 and specific field devices. It helps bridge the gap between the output module and various sensors and actuators on site, making the integration process smoother. In manufacturing plants equipped with various professional sensors and actuators, the TriconeX 1771-IBD enables the TriconeX 3451 to communicate effectively with these devices.

TRICONEX 1771- OBD – This output module can be used in parallel with TRICONEX 3451 to drive actuators and other output devices in industrial processes. It provides additional output capacity and can work in conjunction with the TRICONEX 3451. In water treatment plants, TRICONEX 1771- OBD can control the opening and closing of valves, pumps, and other equipment together with TRICONEX 3451.

The TRICONEX 1785- KTC – Terminal Block Module simplifies the wiring and connection process when using the TRICONEX 3451 in the installation of control systems. It provides a convenient and orderly way to connect wires and cables, reducing the possibility of wiring errors. When installing new control systems in industrial facilities, the TRICONEX 1785-KTC helps to neatly arrange the wiring related to the TRICONEX 3451 for future maintenance and troubleshooting.

Installation and maintenance:

It is crucial to carefully plan the layout of the control cabinet before installing the TRICONEX 3451. Ensure there is sufficient space around the module for proper ventilation. TRICONEX 3451 generates heat during operation, and maintaining optimal temperature levels is crucial for its performance and lifespan. Proper ventilation helps dissipate this heat, preventing module overheating and potential damage. The correct grounding module is crucial. A good grounding connection can protect TRICONEX 3451 from the effects of surges and interference. Surge may be caused by lightning strikes, power grid fluctuations, or equipment failures. If not properly grounded, these surges may damage the module and interfere with the operation of the control system. It is also necessary to verify whether the power supply voltage fully matches the specified requirements of TriconeX 3451. Any voltage deviation may cause unpredictable behavior and potential damage to the module. Using a voltage regulator or UPS (uninterruptible power supply) helps ensure a stable power supply.

For maintenance work, regular visual inspections should become a routine task. Check for any physical signs of damage, such as cracks, dents, or loose connections. During normal operation, physical damage may occur due to vibration, impact, or environmental factors. Early detection of such damage can prevent further problems and ensure the continuous and reliable operation of the module. Check for dust accumulation, as excessive dust can affect the performance of the module and may even cause overheating. In industrial environments, dust usually exists and will deposit on modules over time. It is recommended to regularly use compressed air or specialized cleaning tools to remove dust. Regular diagnostic testing should be conducted to verify the integrity of the output signal. Use specialized diagnostic tools to check for any abnormalities in output voltage, current, or signal integrity. This helps to detect early issues that may affect the normal operation of the control system. Maintaining firmware updates for TriconeX 3451 is another important aspect of maintenance work. TRICONEX regularly releases firmware updates, typically including bug fixes, performance enhancements, and security patches. However, before applying any firmware updates, it is recommended to conduct testing in a non production environment to ensure compatibility with existing control system software and applications. This can prevent any unexpected issues that updates may cause, such as system crashes or communication failures.

Other product models of TRICONEX:

Triconex 3009

Triconex 3624

TRICONEX 3625

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONEX 3721

Triconex 3807

TRICONEX 8111

TRICONEX 8310

TRICONEX 3721

TRICONEX 3624

TRICONEX 3704E

TRICONEX 3564

TRICONEX 4329

TRICONEX 3700A

TRICONEX 3503E

TRICONEX 3006

TRICONEX 8110

TRICONEX 3721

TRICONEX 8310

TRICONEX RXM4200-3

TRICONEX RXM4201

TRICONEX 3624

TRICONEX 4000094-350

TRICONEX 4000103-546

TRICONEX 4000103-550

TRICONEX 4000093-346

TRICONEX 8310

TRICONEX 8110

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626