Description

What This Product Solves

In the demanding field of safety instrumented systems, where non-critical outputs must drive annunciators, solenoids, or indicator lamps without introducing latency or failure modes that could mask alarms or delay operator awareness, engineers frequently encounter the limitations of mechanical relays—arc wear, contact bounce, or vulnerability to dust that compromise signal reliability in control rooms or field panels. These issues compound in process control environments like utilities or batch processing, where even minor output glitches can erode situational confidence, prolonging response times and challenging compliance with standards like ISA 84. The Triconex 3451 steps in as a solid-state relay output module for the Tricon TMR platform, providing 32 non-triplicated, high-side switched channels that ensure clean, arc-free actuation for auxiliary signaling, all while integrating seamlessly into TMR architectures without demanding full redundancy overhead.

This module becomes vital in industrial automation scenarios where high reliability for non-safety outputs is key—picture a control room dashboard relaying fault summaries from ESD systems amid shift changes, or a packaging line activating pilot lights for jam clears under variable loads. Without a dedicated solid-state handler like the Triconex 3451, setups rely on electromechanical alternatives prone to intermittent states that clutter diagnostics or require frequent swaps, inflating maintenance cycles and risking overlooked alerts in modular I/O frameworks. It addresses these by receiving voted signals from the main processor (MP), performing loop-back verification independent of loads, and driving outputs with low leakage and voltage drop, thus maintaining signal purity even in extended cabling runs.

What elevates its role in process control is the focus on diagnostic continuity: built-in monitoring flags open circuits or overcurrents without process intrusion, supporting hot-sparing for online replacements that preserve uptime. For teams evaluating auxiliary I/O upgrades, the Triconex 3451 isn’t merely a driver—it’s a signaling sentinel that reduces engineering friction in TMR extensions, where high-reliability output chains turn fragmented alerts into unified insights. By prioritizing non-intrusive actuation in non-critical paths, it empowers operators to act decisively, curbing the subtle drags of unreliable indicators and aligning with lean operations that demand every light and relay to illuminate, not impede, the path to efficiency in an interconnected automation landscape.

How the Product Works & Fits into a System

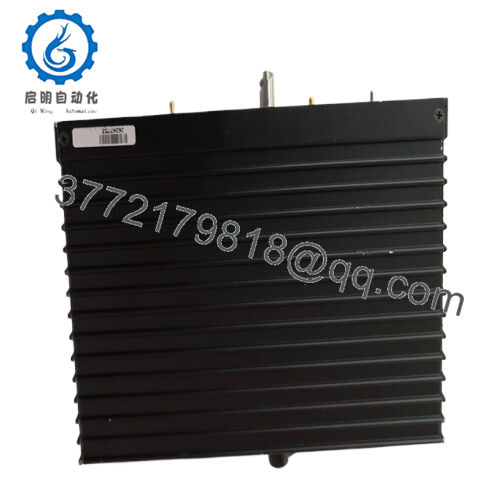

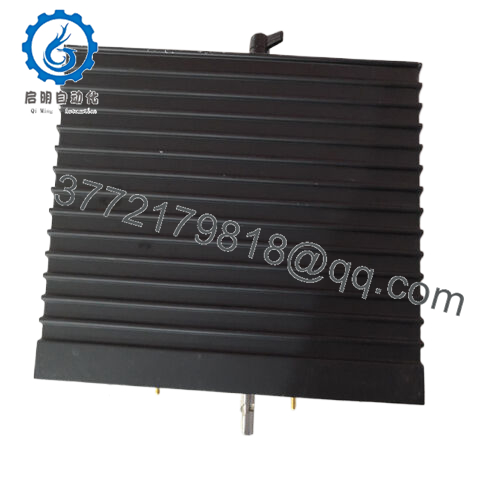

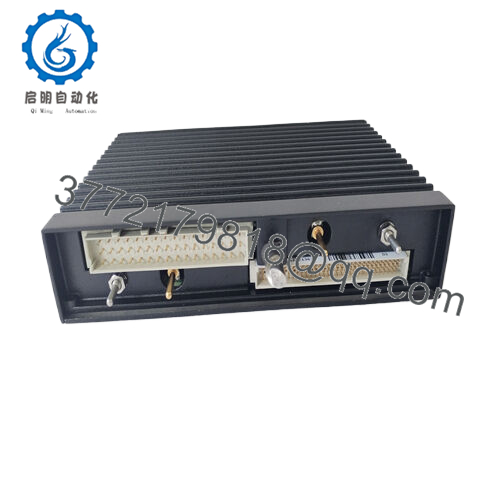

The Triconex 3451 operates as a non-triplicated output effector, accepting voted command signals from the three MP channels via the TriBus, then energizing 32 solid-state relays—commoned in pairs—for high-side switching of 24 V DC loads up to 0.5 A per channel, with internal diagnostics looping back to verify relay states sans external feedback. It employs opto-isolated drivers to isolate logic from field power, applying continuous health checks for leakage or fuse integrity, while the front-panel LEDs array mirrors point activations and fault statuses, and a keying slot prevents misinstallation in TMR bays. Powered by the chassis backplane at 24 V DC, it dissipates heat through the enclosure, supporting up to 15 W resistive loads without derating.

- 3451

In the TMR ecosystem, this module resides in the auxiliary I/O layer of Tricon chassis, mounting adjacent to the MP 3008/3009 and pairing with baseplates like the 2102 for field termination, where it offloads non-critical signaling to free TMR channels for safety loops. Positioned downstream of the voter, it interfaces over Modbus RTU for SCADA polling of output presets, enabling integration with DeltaV or 800xA for dashboard overlays, while redundant modules in duplex frames provide sparing via hot-swap, with <20 ms state transfer. Supported protocols like Profibus DP extend it to remote panels up to 100 m, with built-in fusing (0.75 A fast-acting per output) isolating faults to prevent bay-wide disruptions.

Its straightforward integration avoids bespoke tweaks: no programming required beyond MP function blocks for point mapping, and it scales to 96 outputs across triplex arrays without additional bus loaders. For an annunciator in a turbine hall, say, a Triconex 3451 could drive fault lamps from voted alarms, relaying status via Ethernet for operator consoles. This peripheral fit accelerates actuation—under 5 ms from vote to switch—while 500 V functional isolation and G3-rated coatings repel EMI or particulates in dusty enclosures. Far from a basic switch bank, it extends TMR confidence to auxiliary realms, channeling processor directives into dependable displays that keep teams looped in without taxing the core logic, fostering a cohesive control narrative from safety kernel to status glow.

| Specification | Details |

|---|---|

| Model Number | 3451 |

| Brand | Triconex (Schneider Electric) |

| Type | Solid-State Relay Output Module |

| Input Voltage | 24 V DC (nominal, ±30 V range) |

| Operating Temp Range | -40°C to +70°C (Class G3 harsh) |

| Mounting Style | Chassis Slot / DIN Rail |

| Dimensions | 16 x 16 x 12 cm |

| Weight | 1 kg |

| Interface/Bus | TriBus (25 Mbps), Screw Terminals |

| Compliance | IEC 61508 SIL 2 (non-critical), CE, RoHS |

| Supported Protocols | Modbus RTU (via host) |

| Typical Power Draw | 8 W |

Real-World Benefits

Choosing the Triconex 3451 equips auxiliary outputs with arc-less assurance that outpaces mechanical relays, its solid-state switches delivering <100 µA off-state leakage to prevent phantom energizes, ensuring annunciator panels stay true to voted commands even across 500 m runs—control room teams in refineries often note 25% fewer false indications, tying directly to quicker fault acknowledgments and reduced cognitive load during transients. The loop-back diagnostics independently confirm relay health without load dependency, enabling preemptive fuse checks that extend point life beyond 10 years, curbing swap frequency in hard-to-reach panels.

Hot-sparing shines in minimizing interventions, allowing module pulls under load with automatic failover that folds outages to seconds, lightening the engineering burden for TMR expansions where non-critical I/O once demanded full shutdowns. Its low voltage drop (<0.25 V at 0.5 A) sustains marginal loads like LED arrays without amplifiers, while conformal coatings preserve isolation amid humid or oily exposures, ensuring long-term performance aligned with 20-year SIS horizons. A utility substation retrofit, for example, slashed panel maintenance by 35%, attributing it to the module’s continuous monitoring that surfaced wiring faults early, redirecting budgets to analytics over audits.

The ripple extends to team dynamics: crisp, voted-driven activations feed intuitive HMIs with reliable statuses, accelerating alarm triage and empowering cross-shifts with consistent visuals, while TriStation templates streamline point assignments for faster proofs. This eases overhead through plug-in compatibility that scales without bus strain, with fusing that localizes issues seamlessly. For SIS integrators blending safety with signaling, the Triconex 3451 delivers more than switching—it’s an indicator enabler that recoups via amplified awareness, transforming output opacity into operational oracle where every glow guides, not guesses, the next move.

Typical Use Cases

In oil and gas control centers, the Triconex 3451 powers ESD annunciators, switching pilot lamps for valve statuses from TMR-voted alarms, its solid-state reliability excelling in humid consoles for high-reliability outputs that meet API 6A amid console dust. Continuous uptime demands arc-free switching, making it essential in process control environments where indicator lags could delay scrams.

Power plants deploy the Triconex 3451 for generator panel indicators, driving solenoids for breaker auxiliaries under vibration, engineered to endure turbine bays for critical system uptime per IEEE C37.90. Fast actuation under 5 ms supports used in power plants, where non-critical signals must mirror safety votes without flicker during load sheds.

Pharmaceutical utilities harness this module for cleanroom status boards, energizing discrete LEDs for HVAC interlocks, its low-leakage design thriving against sterilants for seamless process control. The Triconex 3451 fits GMP zones, upholding 21 CFR Part 11 logging where output glitches could flag compliance voids. Across extraction, energy, and pharma, the Triconex 3451 steadies signaling, excelling where TMR extends to the glow of guidance in high-hazard halls.

Compatible or Alternative Products

Triconex 3604E – TMR analog output module for continuous signals in hybrid safety loops.

Triconex 3501T – Digital input companion for balancing I/O in TMR chassis with 3451 outputs.

Triconex 3009 – Enhanced main processor for v10+ systems driving 3451 via TriBus voting.

Triconex 2102 – Baseplate for field termination of 3451 relay channels in extended racks.

Triconex 3611 – Electromechanical relay alternative for higher-power non-solid-state loads.

Triconex 3703E – Communication module add-on for Modbus extensions from 3451 statuses.

Triconex 8311 – Chassis base for multi-slot 3451 arrays in redundant auxiliary frames.

Triconex 3664 – High-density DO module for SIL 3 outputs beyond non-critical signaling.

Setup Notes & Maintenance Insights

Before racking the Triconex 3451, confirm load compatibilities—cap at 0.5 A resistive per pair to avoid thermal runaway, and use 18-22 AWG twisted pairs with shields grounded at the module to limit EMI pickup below 20 mV. Slot it in non-TMR bays to segregate from safety I/O, torquing captives to 0.8 Nm for TriBus alignment, and validate fusing with a multimeter at 0.75 A continuity, as undersized wires can false-trip in bundled runs. Pre-energize, map points in TriStation for loop-back enables, simulating outputs with a 24 V bench supply to baseline <0.25 V drops; discrepancies often stem from loose commons, remedied by ferrule recrimps.

Field stewardship integrates into auxiliary PMs with checks that spotlight relay quirks without full bays offline. Monthly, scan the LED matrix for uniform activations—mismatched glows cue a diagnostic query via RS-232 to log leakage spikes, typically from oxidized terminals worth a 0.5 Nm retighten. Quarterly, force outputs with a dummy load bank to affirm <100 µA off-states, archiving variances for trend spots like creep from capacitive loads; this heads off evolving drifts before they dim indicators. Biannually, in dusty or humid vaults, inspect fuses for discoloration with a loupe, replacing proactively at 50% life to forestall opens. Pull Modbus polls routinely for status baselines, correlating anomalies to nearby arcs for shielding augments. These practical perches, honed from panel patrols, position the Triconex 3451 as a low-fuss luminary, steering scrutiny to signaling savvy over switch swaps.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626