Description

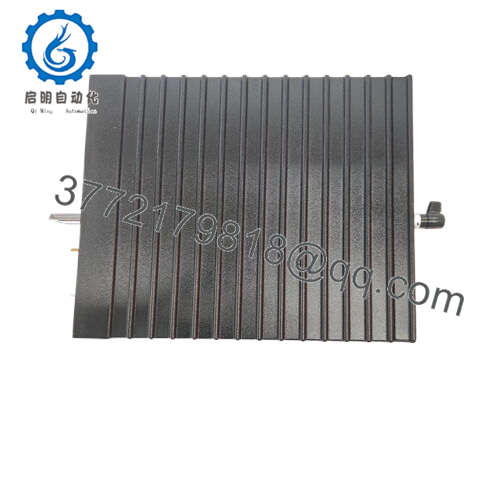

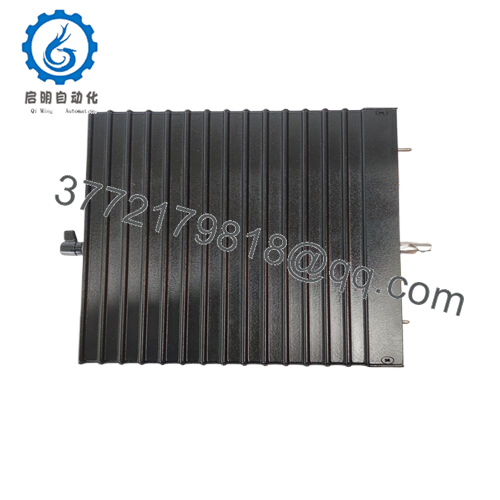

Product Model: TRICONEX 3401

Product Brand: TRICONEX

Product Series: Tricon / Safety System CPU Modules

Product Features:

- High-speed CPU designed for triple modular redundant (TMR) safety systems

- Executes deterministic safety-critical logic for industrial processes

- Compatible with Triconex TMR safety platforms

- Rugged and reliable for harsh industrial environments

Applications & Industry Context

The TRICONEX 3401 is widely used in industries where safety and reliability are non-negotiable, including oil & gas, chemical processing, petrochemical, power generation, and refining. It forms the central processing unit (CPU) of a Triconex TMR system, providing deterministic execution of safety-critical logic.

In oil refineries, the 3401 monitors emergency shutdown systems, flare stacks, and pressure relief devices. In chemical plants, it protects reactors, pipelines, and processing equipment by executing rapid safety interlocks. Power generation facilities use it to manage turbine and generator protection systems, ensuring safety and continuous operation.

The module’s rugged design ensures operation in high-temperature, high-vibration, and high-electrical-noise environments, making it a reliable choice for mission-critical safety applications.

Product Role & System Fit

The TRICONEX 3401 serves as a CPU module within a triple modular redundant safety system, executing high-speed logic for safety-critical processes. It communicates with input/output modules, monitors system health, and ensures continuous operation even if one or more modules fail.

Its primary role is to maintain safety integrity and deterministic control, ensuring that emergency shutdowns, alarms, and interlocks are executed accurately and promptly. Compatible with Triconex TMR platforms, it is suitable for both new installations and system upgrades, offering seamless integration with existing safety architectures.

By maintaining consistent and reliable control, the 3401 module protects personnel, equipment, and the environment, reducing the risk of accidents and unplanned downtime.

Technical Features & Benefits

The TRICONEX 3401 includes several high-performance features:

- Triple Modular Redundancy (TMR): Maintains operation even if one or more modules fail.

- High-Speed Logic Execution: Ensures real-time, deterministic execution of safety-critical tasks.

- System Compatibility: Integrates with Triconex TMR safety platforms and I/O modules.

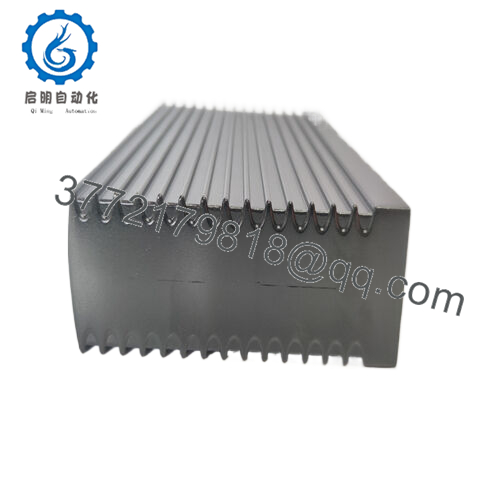

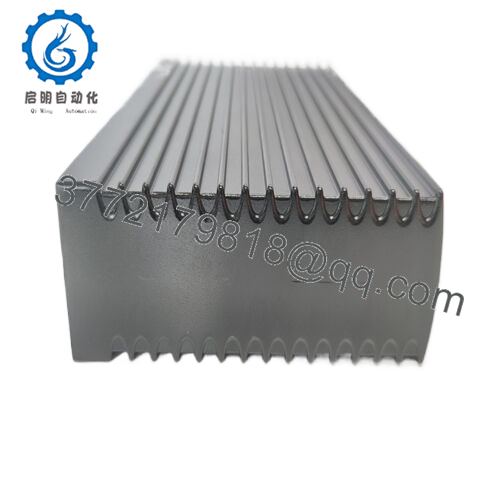

- Rugged Construction: Resistant to vibration, extreme temperatures, and electromagnetic interference.

- Hot-Swappable: Allows module replacement without interrupting system operations.

- Diagnostics & Monitoring: Built-in fault detection and system health monitoring support proactive maintenance.

These features make the 3401 module ideal for high-integrity industrial applications, where precise, reliable safety control is essential.

- 3401

Technical Specifications Table

| Specification | Details |

|---|---|

| Product Model | TRICONEX 3401 |

| Brand | TRICONEX |

| Series | Tricon / Safety System CPU Modules |

| Module Type | TMR Safety CPU Module |

| Function | Executes safety-critical logic and manages system health |

| Compatibility | Triconex TMR safety platforms |

| Hot-Swappable | Yes |

| Diagnostics | Fault detection, system health monitoring, event logging |

| Mounting | Rack-mounted |

| Operating Temperature Range | -20 °C to +70 °C |

| Redundancy | Triple Modular Redundant (TMR) |

| Applications | Oil & gas, chemical, petrochemical, power generation |

| Control Features | Emergency shutdown, safety interlocks, process protection |

Installation & Maintenance Insights

Installing the TRICONEX 3401 requires familiarity with TMR safety system architecture. The module mounts in Triconex racks and connects to redundant backplanes to communicate with I/O modules and other CPU units.

Maintenance recommendations include:

- Ensuring proper alignment and backplane connection before powering the system

- Monitoring LED indicators for operational status and faults

- Replacing faulty modules using hot-swap procedures without system downtime

- Keeping the rack area clean, dust-free, and moisture-free

- Conducting periodic functional tests to ensure accurate safety logic execution

These practices ensure continuous, high-integrity operation and reduce risk in critical industrial processes.

Related Models

- TRICONEX 3501TN2 – High-speed TMR CPU module for safety-critical processes

- TRICONEX 2481 – Safety system controller module for mission-critical applications

- TRICONEX 2351 – Redundant I/O module for TMR safety systems

- TRICONEX 3120 – Input/output module for critical process monitoring

- TRICONEX 3701 – Power supply and communication module for Tricon systems

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626