Description

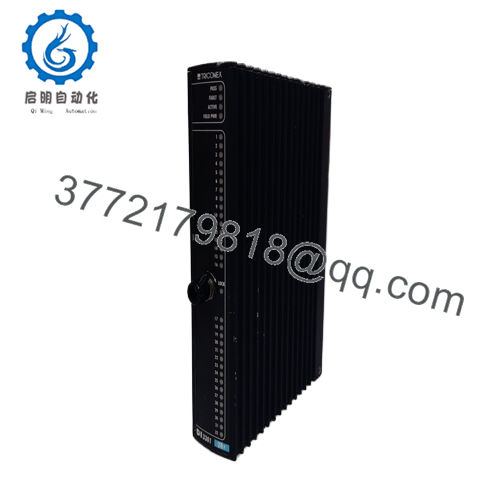

TRICONEX 3301 is a high-performance input/output (I/O) module designed specifically for safety critical applications in industrial control systems. As part of the highly respected TRICONEX product line, it aims to meet the strictest safety standards in the industry. This I/O module is not just a simple data transmission device, it is a key element for seamless information flow between field devices and central control systems in safety instrumented systems.

3301

In the architecture of the control system, TRICONEX 3301serves as a bridge between real-world process variables and control logic. It is connected to various sensors such as pressure sensors, temperature sensors, and flow sensors to collect real-time data of industrial processes. Then, these data are transmitted to the security controller for further processing. At the output end, it sends control signals to actuators (such as valves and motors) based on commands received from the controller. It is highly compatible with multiple industrial communication protocols, making it easy to integrate into existing control system frameworks.

3301

Main features and advantages:

It can quickly sample and convert the analog signals of sensors into digital data that can be processed by the control system. In applications that require real-time monitoring and response, such as emergency parking scenarios, rapid data collection is crucial. For example, in a petrochemical plant, when there is a sudden change in pressure, the TRICONEX 3301 can detect this information within a few milliseconds and transmit it to the controller, allowing the controller to take immediate action.

The TRICONEX 3301 also has excellent signal conditioning capabilities. It can filter out noise and interference in the input signal, ensuring the accuracy and reliability of the data sent to the controller. This is particularly important in industrial environments as electromagnetic interference is more common. By providing clean and stable signals, the TRICONEX 3301helps reduce false alarms and improve the overall performance of the control system.

In terms of hardware design, the TRICONEX 3301 is capable of withstanding harsh industrial environments. Its sturdy structure can protect it from the effects of vibration, dust, and extreme temperatures. This module is designed to be easy to install, with compact dimensions that can be installed in small spaces inside control cabinets. The installation options are flexible and can meet different installation requirements.

Compatibility is another strength of the Triconex 3301. It can be connected to various third-party sensors and actuators, suitable for different industrial settings. It supports multiple communication protocols such as PROFIBUS and PROFINET, making it easy to seamlessly integrate with other components in the control system. In the long run, TRICONEX 3301 has high reliability. Its advanced diagnostic function can continuously monitor the health status of the module, detecting and reporting potential problems before they cause system failures. This proactive maintenance method helps to extend the product’s lifespan and reduce overall maintenance costs.

3301

Technical specifications:

Model3301

Brand Triconex

Type Input/Output (I/O) Module

Power supply 24V DC

Working temperature -40 ° C to 85 ° C

Installation method: DIN rail installation

Supported signal types analog (such as 4-20 mA, 0-10 V), digital

Communication protocols PROFIBUS, PROFINET

Certified IEC 61508 SIL 3, UL, CSA

Environmental protection level IP20

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

3301

Application areas:

In the oil and gas industry, there are numerous potential hazards, and the TRICONEX 3301 is an important component of the Emergency Shutdown (ESD) system. Taking a large offshore oil drilling platform as an example, the TRICONEX 3301 monitors a large number of variables. It closely monitors the pressure inside the pipelines transporting crude oil and natural gas to ensure that the pressure remains within a safe range. Any sudden increase in pressure may indicate blockage or malfunction, and the TRICONEX 3301 is designed to detect such abnormal situations in real-time. It also monitors the temperature of drilling equipment and the chemical composition of the fluid being processed. Once any parameter deviates from the normal operating range, it can quickly trigger the ESD system and stop operation to prevent potential explosions, oil spills, and environmental disasters.

Chemical plants also heavily rely on TRICONEX 3301 for their Safety Instrumented Systems (SIS). These facilities handle highly reactive and often hazardous chemicals. TRICONEX 3301 is used to control and protect processes such as chemical synthesis, distillation, and storage. For example, in a factory that produces fertilizers, it controls the flow of raw materials into the reactor to ensure that chemical reactions occur under precisely controlled conditions. It also monitors safety valves and other critical equipment to ensure that appropriate safety measures can be taken immediately in the event of overpressure or unexpected reactions.

Power plants, whether coal-fired, nuclear, or renewable energy, utilize the TRICONEX 3301 to enhance their safety and control mechanisms. In coal-fired power plants, it helps monitor the performance of boilers, turbines, and generators. It can detect abnormal vibrations and other issues in the steam turbine, which, if ignored, may lead to mechanical failures. By identifying such issues in a timely manner, TRICONEX 3301 enables power plant operators to take corrective measures to prevent costly equipment damage and power outages. In nuclear power plants, safety is of utmost importance, and TRICONEX 3301 is used to control and protect nuclear reactors, ensuring that they operate within strict safety parameters.

Related products:

TRICONEX 3503E – can be used in conjunction with TRICONEX 3301 to expand the overall I/O capability of the control system. It provides additional input and output channels for more comprehensive monitoring and control of industrial processes.

TRICONEX 3805E – a communication module that enhances the connectivity of TRICONEX 3301. By integrating with this module, TRICONEX 3301 can communicate more effectively with other components in the control system network, such as remote sensors and actuators, improving overall communication efficiency within the system.

TRICONEX 4351B – a redundant controller module. In some applications that require high system redundancy, the TRICONEX 3301 can be used in conjunction with the TRICONEX 4351B to ensure continuous operation in the event of controller failure.

TRICONEX 1781- A power module designed to provide stable and reliable power to TRICONEX 3301 and other devices connected in the control system. A stable power supply is crucial for the normal operation of the TRICONEX 3301, as this module ensures that the power requirements are met.

TRICONEX 1771- IBD – an interface module that simplifies the connection between TRICONEX 3301 and specific field devices. It helps to bridge the gap between I/O modules and various sensors and actuators on site, making the integration process smoother.

TRICONEX 1771- OBD – This output module is designed specifically for use with TRICONEX 3301 to drive actuators and other output devices in industrial processes. It ensures that the control signals of TRICONEX 3301 can be effectively converted into on-site operations.

TRICONEX 1785- KTC – a wiring terminal module that simplifies the wiring and connection of TRICONEX 3301 during the installation of control systems. It provides a convenient and orderly way to connect wires and cables, reducing the possibility of wiring errors.

Installation and maintenance:

Before installing the TRICONEX3301 , it is necessary to carefully plan the layout of the control cabinet. Ensure there is sufficient clearance around the module for proper ventilation. Proper ventilation is crucial as the TRICONEX 3301 generates heat during operation, and maintaining optimal temperature levels is essential for its performance and lifespan. The correct grounding module is crucial. Appropriate grounding connections can protect the TRICONEX 3301 from the effects of surges and interference, otherwise it may cause module failure or damage. It is also necessary to verify whether the power supply voltage fully matches the specified requirements of TRICONEX 3301 . Any deviation in voltage can lead to unpredictable behavior and may damage the module.

For maintenance, regular visual inspections should be conducted. Look for any signs of physical damage, such as cracks, dents, or loose connections. Check for dust accumulation, as excessive dust can affect the performance of the module and may even cause overheating. It is recommended to conduct regular signal diagnosis. Use specialized diagnostic tools to verify the integrity of input and output signals. This helps to detect potential issues that may affect the normal operation of the control system early. Maintaining firmware updates for Triconex 3301 is also an important aspect of maintenance. TRICONEX regularly releases firmware updates, typically including bug fixes, performance enhancements, and security patches. However, before applying any firmware updates, it is recommended to conduct testing in a non production environment to ensure compatibility with existing control system software and applications.

Other product models of TRICONEX:

Triconex 3009

Triconex 3624

TRICONEX 3625

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONEX 3721

Triconex 3807

TRICONEX 8111

TRICONEX 8310

TRICONEX 3721

TRICONEX 3624

TRICONEX 3704E

TRICONEX 3564

TRICONEX 4329

TRICONEX 3700A

TRICONEX 3503E

TRICONEX 3006

TRICONEX 8110

TRICONEX 3721

TRICONEX 8310

TRICONEX RXM4200-3

TRICONEX RXM4201

TRICONEX 3624

TRICONEX 4000094-350

TRICONEX 4000103-546

TRICONEX 4000103-550

TRICONEX 4000093-346

TRICONEX 8310

TRICONEX 8110

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626