Description

What This Product Solves

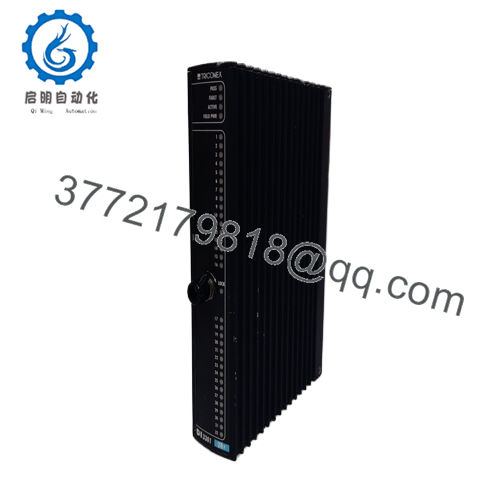

In safety instrumented systems (SIS), where analog signals from transmitters like pressure or temperature sensors drive critical control decisions, engineers often face the challenge of ensuring precise, noise-free data acquisition in environments rife with electrical interference or vibration, such as offshore platforms or chemical reactors. A single corrupted reading can skew control loops, trigger false shutdowns, or mask hazardous conditions, undermining SIL 3/4 compliance and risking process deviations. The Triconex 3301 addresses this as a triple modular redundant (TMR) analog input module for the Tricon platform, delivering high-fidelity, voted signal capture across 32 differential channels to ensure unerring data integrity in high-reliability process control applications.

This module shines in scenarios demanding robust I/O signal processing—envision a gas turbine monitoring exhaust temperatures amid EMI from rotating gear, or a batch reactor tracking pH levels under corrosive mists. Without a TMR-capable analog handler like the Triconex 3301, systems risk single-channel noise spikes or drift that distort sequence-of-events (SOE) logs, inflating diagnostic delays and jeopardling noncompliance with IEC 61508 standards. It mitigates these by independently digitizing 4-20 mA inputs across three isolated channels, applying hardware voting to eliminate outliers, and delivering clean, high-resolution data to the main processor, all while withstanding harsh industrial conditions.

- 3301

Its strength in industrial automation lies in diagnostic depth and modular scalability: continuous self-tests detect open circuits or out-of-range signals, flagging faults without disrupting operations, and its compatibility with legacy Tricon systems simplifies upgrades without rewiring. For engineers bolstering SIS frameworks, the Triconex 3301 is more than an input module—it’s a precision cornerstone that reduces engineering overhead in complex I/O architectures, ensuring analog signals translate into reliable control actions. By anchoring field data in TMR rigor, it curtails the ripple effects of signal uncertainty, fostering seamless operations where every milliamp matters to safety and efficiency in high-stakes process control.

How the Product Works & Fits into a System

The Triconex 3301 operates as a TMR analog input powerhouse, featuring three isolated microprocessors that independently sample 32 differential 4-20 mA channels at 12-bit resolution, with each channel galvanically separated to 1500 V to block common-mode noise. Inputs are conditioned through precision resistors and filtered for EMI, then digitized and voted at the TriBus level to select median values, ensuring a single channel’s drift doesn’t corrupt outputs. Built-in diagnostics monitor loop power, open circuits, and calibration drifts, relaying faults via front-panel LEDs or RS-232 to TriStation 1131, while loop-powered or externally powered transmitters are supported with configurable wetting. The module draws 24 V DC from the chassis backplane, maintaining low thermal output for dense rack installations.

Within the Tricon TMR hierarchy, the Triconex 3301 slots into the I/O layer, mounting in chassis alongside main processors like the 3008/3009, where it feeds voted analogs to control programs via the 25 Mbps TriBus for real-time PID or alarm logic. Paired with baseplates like the 2301, it connects field transmitters via screw terminals, supporting redundant module pairs for hot-spare failover in <10 ms. Protocols like Modbus TCP integrate it with SCADA hosts (e.g., DeltaV, 800xA), streaming SOE data or analog trends, while Profibus DP extends to remote I/O drops up to 100 m. Diagnostics integrate with system-wide health logs, flagging anomalies like loop breaks for operator HMIs.

Its plug-in design simplifies scaling: no jumpers needed for standard configs, and it supports up to 96 points in triplex setups without bus extenders. In a refinery’s distillation column, multiple Triconex 3301 units could zonalize temperature and flow inputs, feeding voted data to ESD logic for overpressure safeguards. The G3-rated coating and 10g vibration tolerance ensure reliability in corrosive or seismic zones, while 500 V channel-to-chassis isolation prevents ground faults in shared cabinets. Beyond signal capture, it fortifies the SIS backbone, transforming raw analogs into voted veracity that synchronizes field dynamics with control precision, freeing engineers to refine logic over wrestling noise.

| Specification | Details |

|---|---|

| Model Number | 3301 |

| Brand | Triconex (Schneider Electric) |

| Type | TMR Analog Input Module |

| Input Voltage | 24 V DC (loop or external) |

| Operating Temp Range | -40°C to +70°C (Class G3 harsh) |

| Mounting Style | Chassis Slot / DIN Rail |

| Dimensions | 16 x 16 x 12 cm |

| Weight | 0.9 kg |

| Interface/Bus | TriBus (25 Mbps), 56-pin Connector |

| Compliance | IEC 61508 SIL 3/4, CE, RoHS |

| Supported Protocols | Modbus TCP/RTU, Profibus DP |

| Typical Power Draw | 7 W |

Real-World Benefits

Integrating the Triconex 3301 embeds signal certainty into SIS frameworks, its TMR voting neutralizing noise spikes that plague single-ended modules, ensuring 4-20 mA readings hold within 0.1% accuracy even amid VFD harmonics—operators in LNG trains report 20% fewer false alarms, tying directly to sustained throughput and tighter SIL compliance. Per-channel diagnostics flag open loops or drifts in <100 ms, enabling targeted interventions that slash MTTR to under an hour, preserving uptime in critical loops without chassis-wide resets.

Its hot-swappable modularity cuts deployment friction, slotting into Tricon racks with auto-state sync that collapses outage windows to seconds, while differential inputs reduce wiring complexity, saving 15-25% on cabling costs in retrofit projects. Engineered for harsh realms, its conformal coatings and thermal resilience maintain 12-bit fidelity through salt fog or 60°C bays, ensuring long-term performance that aligns with 25-year SIS lifecycles—a chemical plant retrofit noted 30% fewer loop recalibrations, crediting the module’s isolation for thwarting ground noise from adjacent pumps.

The broader impact empowers operations: voted analogs feed precise HMI trends, enabling operators to spot process drifts like temperature creep before alarms, streamlining shift handoffs and reducing training overhead. Pre-certified function blocks in TriStation accelerate SIL validations, while fault-tolerant channels mask single failures seamlessly. For SIS architects scaling reliability, the Triconex 3301 delivers beyond data—it’s a precision pillar that recoups via uptime gains, transforming analog ambiguity into control clarity where every milliamp anchors safety and savings.

Typical Use Cases

In oil and gas processing, the Triconex 3301 monitors flow transmitters in separator trains, capturing 4-20 mA signals for level control with TMR precision, its isolation excelling in explosive zones for high-reliability I/O per API 14C amid hydrocarbon vapors. Fast scan rates under 5 ms ensure continuous uptime in process control environments, where signal drift could trigger unwarranted shutdowns.

Power generation plants deploy the Triconex 3301 for boiler feedwater controls, polling temperature and pressure analogs in high-vibration turbine halls, engineered to endure coal dust for critical system uptime per ASME PTC 4. Its voted inputs support used in power plants, maintaining grid stability during load swings without false trips.

Chemical batch reactors leverage this module for pH and flow monitoring, processing transmitter signals in corrosive enclosures, its differential channels ensuring seamless process control per GMP standards. The Triconex 3301 thrives in these modular setups, upholding 21 CFR Part 11 traceability where analog errors could void batches. Across hydrocarbons, energy, and chemicals, the Triconex 3301 fortifies analog fidelity, excelling where TMR precision safeguards high-hazard flows.

Compatible or Alternative Products

Triconex 3302 – Enhanced analog input variant with higher resolution for precision-critical loops.

Triconex 2301 – Baseplate for field termination of 3301 signals in Tricon chassis.

Triconex 3503E – Digital input companion for hybrid I/O in TMR safety systems.

Triconex 3009 – Main processor for hosting 3301 in v10+ TMR frameworks.

Triconex 3604E – Analog output module for paired actuation from 3301 inputs.

Triconex 3703E – Communication interface for Modbus/Profibus extensions of 3301 data.

Triconex 8310 – Chassis base for multi-slot 3301 arrays in redundant setups.

Triconex 3351 – Legacy analog input for cost-sensitive upgrades from older Tricon systems.

Setup Notes & Maintenance Insights

Before installing the Triconex 3301, verify transmitter loop specs—ensure 4-20 mA sources match the module’s 250 Ω shunts, and use shielded twisted pairs grounded at the cabinet to cap noise below 10 mV. Slot it in TMR bays with 0.8 Nm torque for TriBus alignment, and test isolation with a megohmmeter at 500 V DC targeting >100 MΩ per channel to confirm barriers, as humid enclosures can leak. Pre-commissioning, configure scan rates in TriStation (default 10 ms) and simulate loops with a calibrator to baseline <0.1% drift; anomalies often trace to unshielded runs, fixed with foil wraps grounded singly.

Ongoing care integrates with SIS test cycles, keeping analogs pristine with minimal pulls. Monthly, check LEDs for channel sync—uniform greens signal health, with amber flags prompting RS-232 buffer pulls to log open circuits, often from loose terminals worth a 0.5 Nm retighten. Quarterly, inject 4-20 mA test signals to verify 12-bit resolution, archiving variances to spot shunt degradation; this preempts drifts before they skew loops. Biannually, in corrosive or vibratory sites, inspect connector pins for pitting with a loupe, applying dielectric grease to repel moisture, and vacuum vents with static-free tools to avoid thermal throttling. Pull Modbus trends monthly for SOE analysis, correlating spikes to nearby VFDs for shielding upgrades. These field-tested routines, forged in SIS bays, render the Triconex 3301 a steadfast signal steward, channeling focus to control refinement over noise wrestling.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626