Description

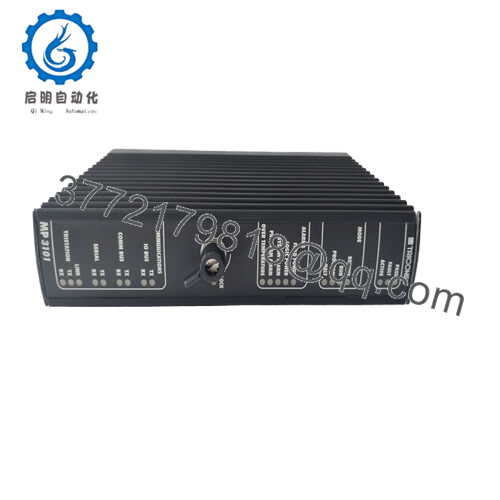

TRICONEX 3101 is a high-performance safety controller module designed to meet the strictest safety standards in the industrial field. As part of the well-known TRICONEX product portfolio, it is designed specifically for Safety Instrumented Systems (SIS) and critical control applications. This is not just an ordinary controller, but a comprehensive solution that is at the core of ensuring industrial process safety.

3101

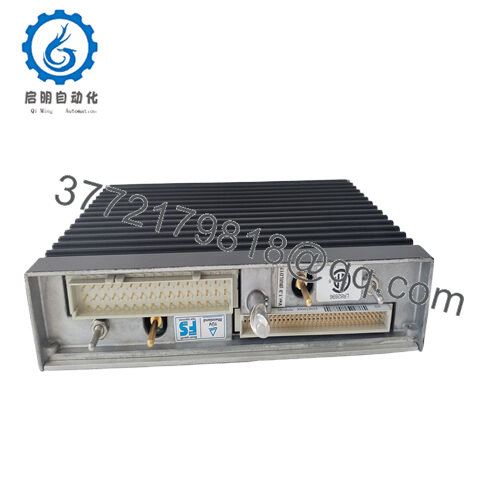

In the architecture of the control system, TRICONEX3101 serves as the central decision-making unit. It seamlessly connects with a wide range of input/output (I/O) modules, sensors, and actuators. The sensor provides real-time data on process conditions to the TRICONEX 3101, and the controller uses advanced algorithms to process this information. Based on the processed data, it sends control signals to the actuator to maintain normal operation or initiate safety related operations in emergency situations. It is highly compatible with multiple industrial communication protocols and can be smoothly integrated into existing control system settings, whether it is large industrial complexes or smaller, more specialized factories.

3101

Main features and advantages:

This innovative design means that the controller has three independent processing channels. During normal operation, three channels process input data simultaneously. Then compare the results of these channels and use a majority voting mechanism to determine the output. If one of the channels fails, the remaining two channels can still continue to operate, ensuring that the controller does not interrupt its work. This high redundancy significantly improves the availability and reliability of the system, reducing the risk of unexpected shutdowns caused by controller failures.

The TRICONEX3101also has an impressive processing speed. It can quickly analyze large amounts of data and execute complex control algorithms in a fraction of a second. This fast response time is crucial in safety critical applications, where any delay in detecting and responding to abnormal conditions can lead to catastrophic consequences. Whether it is detecting a sudden increase in pressure in a chemical reactor or a voltage drop in a power generation system, TRICONEX 3101 can respond in real-time and initiate appropriate safety measures.

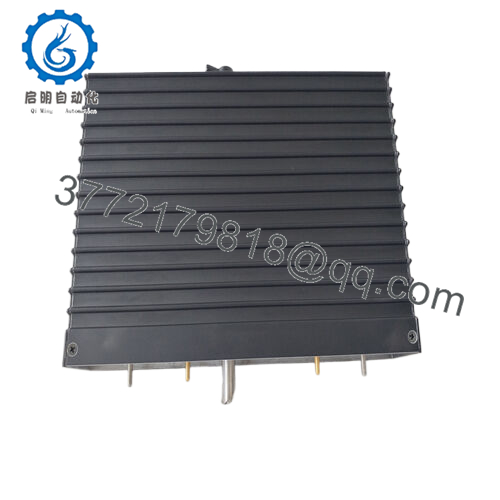

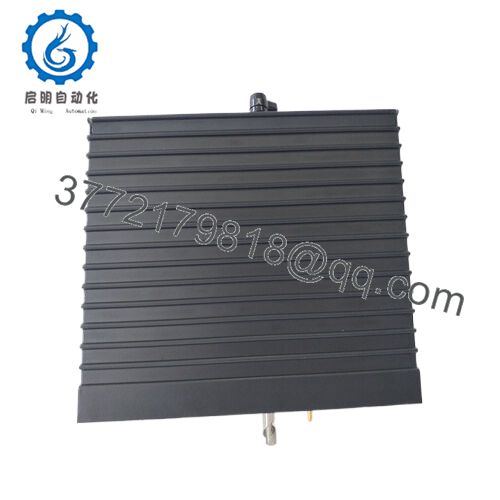

In terms of hardware design, the TRICONEX 3101 is capable of withstanding harsh industrial environments. Its sturdy structure can prevent the effects of vibration, electromagnetic interference, and extreme temperatures. This module is designed to be easy to install, with compact dimensions that can be installed in small spaces inside control cabinets. There are various installation options to meet different installation preferences. In addition, it has good compatibility with various third-party I/O devices, sensors, and actuators. This makes it suitable for various industrial settings as it can be integrated with existing equipment, reducing the need for expensive replacements. In the long run, the TRICONEX 3101 has excellent reliability. Its advanced self diagnostic function can continuously monitor the health status of the module, detecting and reporting potential issues before they escalate into system failures. This proactive maintenance method helps to extend the product’s lifespan and reduce overall maintenance costs.

3101

Technical specifications:

Model3101

Brand Triconex

Type safety controller module

Power supply 24V DC

Working temperature -40 ° C to 85 ° C

Installation method: DIN rail installation

Interfaces PROFIBUS, PROFINET, Ethernet/IP, serial

Certified IEC 61508 SIL 3, UL, CSA

Natural convection method for heat dissipation

Environmental grade IP20

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

3101

Application areas:

In the petrochemical industry, handling flammable and explosive substances is the norm, and TriconeX3101 is an important component of emergency shutdown (ESD) systems. For example, in large refineries, it continuously monitors a large number of parameters, such as the pressure inside pipelines transporting highly flammable crude oil derivatives, the temperature of reactors undergoing complex chemical reactions, and the flow rates of various process fluids. Once any parameter deviates from the safe operating range, the TRICONEX 3101 can immediately trigger a parking procedure to prevent potential explosions, leaks, and subsequent environmental disasters.

Whether it is power plants that rely on fossil fuels, nuclear energy, or renewable energy, they are highly dependent on the TRICONEX 3101. In coal-fired power plants, it ensures the safe operation of boilers, turbines, and generators by closely monitoring factors such as steam pressure, rotor speed, and current. Malfunctions of these components may result in power outages, equipment damage, and even endanger the lives of power plant workers. TRICONEX3101is like a vigilant sentinel, ready to intervene at any time to maintain the stability of the power generation process. Similarly, safety is crucial in nuclear power plants, as this equipment is used to control and protect the nuclear reactor, ensuring that it operates within strict safety parameters.

Chemical manufacturing factories are another area where TriconeX 3101 plays a key role. These factories process a variety of chemicals, some of which are highly reactive. TRICONEX3101 is used to manage and ensure processes such as chemical synthesis, distillation, and storage. It controls the opening and closing of valves, the operation of pumps, and other critical equipment to ensure that chemical reactions occur under precisely controlled conditions. This helps prevent accidental reactions, leaks, and the release of harmful substances into the environment. Its application in industrial safety and control systems makes it an indispensable asset in multiple industries.

3101

Related products:

TRICONEX 3503E – This is an I/O module that perfectly complements the TRICONEX 3101, providing additional input and output channels. This makes the monitoring and control of industrial processes more comprehensive, expanding the management scope of the system based on TRICONEX 3101.

TRICONEX 3805E – This is a communication module that can be integrated with TRICONEX 3101 to enhance its connectivity. It allows for better interaction with other components in the control network, such as remote sensors and actuators, improving the overall communication efficiency of the system.

TRICONEX 4351B – This is another redundant controller module in the TRICONEX family. In some applications that require higher redundancy, it can be used in parallel with the TRICONEX 3101 to further protect the control system from potential faults.

TRICONEX 1781- This is a power module designed to provide stable and reliable power to TRICONEX 3101 and other devices connected in the control system. A stable power supply is crucial for the normal operation of the TRICONEX 3101, and this module is designed to ensure this.

TRICONEX 1771- IBD – This is an interface module that simplifies the connection between TRICONEX 3101 and specific field devices. It helps to build a bridge between the controller and various sensors and actuators on site, making the integration process smoother.

TRICONEX 1771- OBD – This is an output module designed specifically for use with the TRICONEX 3101 to drive actuators and other output devices in industrial processes. It ensures that the control signals of TRICONEX 3101 can be effectively converted into on-site operations.

TRICONEX 1785- KTC – This is a terminal block module that simplifies the wiring and connection process when installing control systems using the TRICONEX 3101. It provides a convenient and orderly way to connect wires and cables, reducing the possibility of wiring errors.

Installation and maintenance:

It is crucial to carefully plan the layout of the control cabinet before installing TRICONEX 3101. Ensure there is sufficient space around the module for proper ventilation. Proper ventilation is crucial as the TRICONEX 3101 generates heat during operation, and maintaining optimal temperature levels is essential for its performance and lifespan. The correct grounding module is crucial. A good grounding connection can protect TRICONEX 3101 from the effects of surges and interference, otherwise it may cause module failure or damage. It is also necessary to carefully check whether the power supply voltage fully matches the specified requirements of TRICONEX3101. Any voltage deviation may cause unpredictable behavior and potential damage to the module.

Regular visual inspections should be a routine part of maintenance work. Check for signs of physical damage, such as cracks, dents, or loose connections. Check for dust accumulation, as excessive dust can affect the performance of the module and may even cause overheating. Regular signal diagnosis is also highly recommended. Use specialized diagnostic tools to verify the integrity of input and output signals. This helps to detect potential issues that may affect the normal operation of the control system early. Maintaining firmware updates for the TRICONEX 3101 is also an important aspect of maintenance. TRICONEX regularly releases firmware updates, typically including bug fixes, performance enhancements, and security patches. However, before applying any firmware updates, it is recommended to conduct testing in a non production environment to ensure compatibility with existing control system software and applications.

Other product models of TRICONEX:

Triconex 3009

Triconex 3624

TRICONEX 3625

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONEX 3721

Triconex 3807

TRICONEX 8111

TRICONEX 8310

TRICONEX 3721

TRICONEX 3624

TRICONEX 3704E

TRICONEX 3564

TRICONEX 4329

TRICONEX 3700A

TRICONEX 3503E

TRICONEX 3006

TRICONEX 8110

TRICONEX 3721

TRICONEX 8310

TRICONEX RXM4200-3

TRICONEX RXM4201

TRICONEX 3624

TRICONEX 4000094-350

TRICONEX 4000103-546

TRICONEX 4000103-550

TRICONEX 4000093-346

TRICONEX 8310

TRICONEX 8110

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626