Description

The TriconeX 3009 is a high-performance module that occupies a core position in the Triconex product line, known for its outstanding performance in safety critical control systems.

3009

As part of the Triconex Triple Modular Redundancy (TMR) architecture, the Triconex 3009 is designed to execute complex control algorithms in real-time and process large amounts of data. In TMR configuration, three identical TRICONEX3009 modules run in parallel. Each module independently processes the same input signal from sensors distributed throughout the industrial process. Then, the outputs of these three modules are compared through a voting mechanism. This two out of three voting method ensures that even if one module experiences hardware or software failures, the correct control output can still be generated based on the consensus of two normal modules.

3009

Main features and advantages:

Its high-speed processing capability enables it to quickly analyze incoming sensor data, enabling instant decision-making in industrial processes. In high-risk scenarios, such as detecting gas leaks in refineries, the TRICONEX 3009 can identify anomalies within milliseconds and initiate appropriate corrective measures. It has high computational accuracy, which can minimize the risk of misreading sensor signals and reduce the possibility of false alarms. This accuracy is crucial for maintaining the integrity of safety critical systems, as incorrect decisions can have serious consequences.

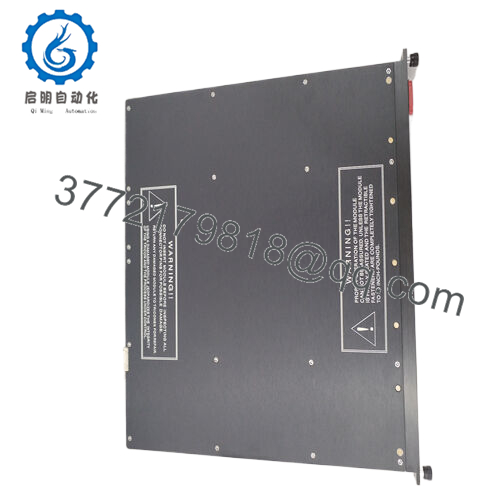

In terms of hardware design, the TRICONEX 3009 has been carefully designed to withstand the harshest industrial conditions. Its sturdy casing can withstand vibrations, extreme temperatures, and electromagnetic interference. This makes it suitable for deployment in remote and challenging locations, such as offshore platforms or in petrochemical plant centers, where environmental conditions may be particularly harsh. The design of this module emphasizes ease of installation and maintenance. It adopts a compact external dimension, which can effectively utilize the space inside the control cabinet, and its standardized connectors and interfaces simplify the integration process. This not only saves installation time, but also reduces the complexity of system maintenance, as technicians can easily access and repair the module when needed.

Compatibility is an important advantage of the TRICONEX 3009 . It supports a wide range of communication protocols and can interface with various sensors, actuators, and other control modules. Whether using 4-20 mA signals to connect traditional analog sensors or integrating with modern digital communication devices through Ethernet or other high-speed protocols, the TRICONEX 3009 can establish seamless communication links. The diversity of communication options enables engineers to build customized security and control systems that can interface with existing factory infrastructure, regardless of the age or type of other components in the factory infrastructure.

In terms of long-term reliability, the Triconex 3009 benefits from Triconex TMR technology. Triple module redundancy not only provides fault tolerance, but also extends the overall service life of the module. If a component in one of the modules fails, the system can still operate continuously. In addition, the module adopts advanced thermal management design to ensure continuous operation even under heavy load conditions without overheating. The combination of fault tolerance and thermal efficiency contributes to the long-term reliability of the TRICONEX3009 , reducing the need for frequent replacement and lowering maintenance costs over time.

3009

Technical specifications:

Model 3009

Brand Triconex

Type safety related processor module

Power supply 24V DC, with a tolerance of ± 10%

Working temperature -40 ° C to+85 ° C

Installation method: DIN rail installation, easy to install in standard control cabinets

Dimensions 120mm x 70mm x 40mm

Weight 0.6 kg

Interface RS-485 is used for serial communication, Ethernet is used for high-speed data transmission, and dedicated sensor input and actuator output interfaces

Certified IEC 61508 SIL 3 for safety related applications

The natural convection heat dissipation method ensures reliable operation in most applications without the need for additional cooling devices

Environmental protection level IP20, can prevent solid objects with a diameter greater than 12.5 mm from entering, suitable for indoor use in industrial environments

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

Application areas:

Safety is crucial in the oil and gas industry, covering various aspects from offshore drilling platforms to onshore refineries. Offshore drilling platforms operate in harsh and remote environments, requiring handling of high-pressure wellbores and highly flammable materials. The TRICONEX 3009 is integrated into a Safety Instrumented System (SIS) for monitoring critical parameters such as well pressure, gas leakage, and equipment vibration. Once any abnormal situation occurs, it can quickly initiate emergency shutdown procedures to prevent catastrophic events such as blowouts that may cause environmental disasters and significant economic losses.

The onshore refinery has a complex network of pipelines, reactors, and distillation towers, relying on the TRICONEX 3009to maintain its operational safety and efficiency. It processes data from a large number of sensors, including temperature sensors in reactors, pressure transmitters in pipelines, and flow meters in processing units. By accurately analyzing these data, the TRICONEX 3009 ensures that the refinery process remains within safe operating limits. For example, if the reaction in the cracking unit begins to deviate from the optimal temperature range, TRICONEX 3009 can adjust the cooling water flow rate or change the feed rate to restore normal process control.

The petrochemical industry, which produces highly reactive chemicals, is also an area where TriconeX 3009excels. Petrochemical plants need to strictly control chemical reactions to prevent explosions, harmful substance leaks, and environmental pollution. TRICONEX 3009 is responsible for managing safety critical functions such as controlling the addition of reactants, monitoring the integrity of storage tanks, and operating emergency ventilation systems. For example, in a plastic production factory, it ensures that the polymerization process is carried out under the correct conditions to prevent the formation of hazardous by-products.

Power generation facilities, especially large thermal power plants, also benefit from the TRICONEX 3009. These factories have complex mechanical equipment, including turbines, boilers, and generators. TRICONEX 3009is used to monitor safety related aspects of these components. It can detect abnormal vibrations in the turbine, which may indicate the presence of mechanical problems; It can also monitor the water level in the boiler to prevent dry burning, equipment failure, and power outages. Overall, the TRICONEX 3009 is an important component of industrial automation and control systems, meeting the demand for reliable safety and control mechanisms in challenging industrial environments.

Related products:

TriconeX 3008- Another high-performance module in the Triconex family. It is similar in functionality to the TRICONEX 3009, but may have different processing speeds or memory capacities, making it suitable for applications with slightly different performance requirements.

Triconex I/O modules (various models) – These modules are directly compatible with the Triconex 3009 and are critical components for interfacing with external sensors and actuators. They provide the necessary input channels to receive sensor data, as well as output channels to control actuators, enabling the TRICONEX 3009 to interact with industrial processes.

The Triconex power module is crucial for providing stable and reliable power to the Triconex 3009 and the entire TMR system. They ensure that the module can operate smoothly even in the event of power fluctuations, which is crucial for maintaining the integrity of safety critical systems.

Triconex communication module – such as modules that support PROFINET or PROFIBUS protocols. These modules can be integrated with the TRICONEX 3009 to enhance its communication capabilities, enabling it to connect more effectively with other devices and systems in industrial networks.

Triconex Expansion Modules – These modules can be used to increase the capacity of TMR systems. When the demand for industrial applications grows, they can provide additional processing power, memory, or I/O channels, and work in conjunction with the TRICONEX 3009 to meet these expansion needs.

Triconex diagnostic modules – These modules are designed to monitor the health status of the Triconex 3009 and the entire TMR system. They provide valuable diagnostic information such as module status, error codes, and performance metrics, which are crucial for proactive maintenance and troubleshooting.

TRICONEX 3003- EMPII – Although its main functions may differ from those of TRICONEX 3009, it can become a part of a larger Triconex control system. It may be involved in specific aspects of control or monitoring, and in some settings, it can work in conjunction with the TRICONEX 3009 to achieve comprehensive system functionality.

Installation and maintenance:

Before installing the TRICONEX 3009, integrators should carefully consider several important factors. Firstly, it is necessary to carefully plan the layout of the control cabinet. Sufficient space must be reserved around the module to ensure proper ventilation. Insufficient ventilation may lead to heat accumulation, which may have a negative impact on the performance and service life of the TRICONEX 3009. A well ventilated control cabinet helps dissipate heat during module operation, ensuring its stable operation.

Proper grounding is also crucial. The TRICONEX 3009 must be connected to a reliable ground source to prevent power surges and electromagnetic interference. A reliable grounding connection not only protects the module, but also ensures accurate signal transmission. Any electromagnetic interference can lead to incorrect sensor readings or unstable control outputs, which can be very dangerous in safety critical applications. In addition, integrators should check any spacing requirements around the module. This helps prevent accidental contact with other components during installation and operation, reducing the risk of module short circuits or mechanical damage.

For maintenance, it is recommended to conduct regular visual inspections. Technicians should inspect the module for any physical signs of damage, such as cracks in the casing, loose connectors, or signs of overheating. These inspections should be conducted at least once every quarter, and in harsh industrial environments, the inspection frequency should be higher as modules may be more prone to wear and tear. Signal diagnosis is also crucial. Technicians should regularly verify the integrity of input and output signals using built-in diagnostic tools or connected monitoring software. This helps with early detection of any issues related to sensors or actuators connected to the TRICONEX3009. For example, if there is abnormal fluctuation in the input signal of the sensor, it may indicate a problem with the sensor itself or the connection between the sensor and the module.

Other product models of TRICONEX:

Triconex 3009

Triconex 3624

TRICONEX 3625

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONEX 3721

Triconex 3807

TRICONEX 8111

TRICONEX 8310

TRICONEX 3721

TRICONEX 3624

TRICONEX 3704E

TRICONEX 3564

TRICONEX 4329

TRICONEX 3700A

TRICONEX 3503E

TRICONEX 3006

TRICONEX 8110

TRICONEX 3721

TRICONEX 8310

TRICONEX RXM4200-3

TRICONEX RXM4201

TRICONEX 3624

TRICONEX 4000094-350

TRICONEX 4000103-546

TRICONEX 4000103-550

TRICONEX 4000093-346

TRICONEX 8310

TRICONEX 8110

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626