Description

Real-World Use & Application Scenarios

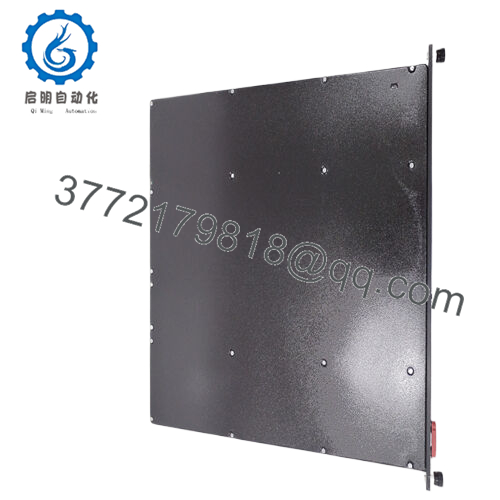

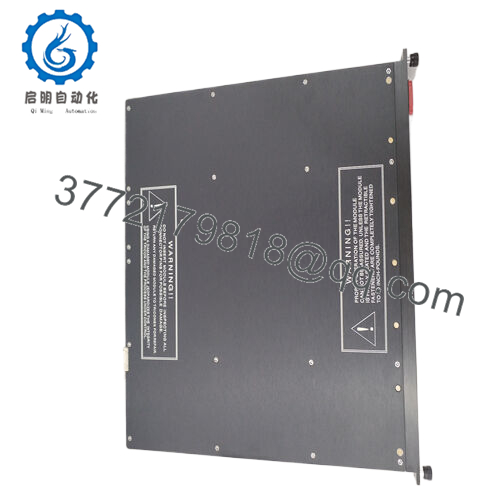

The TRICONEX 3009 main processor module is a cornerstone of industrial safety and control systems, used extensively across a variety of sectors such as chemical processing, oil and gas, power generation, and transportation. Engineered for environments demanding unmatched reliability and redundancy, this module serves crucial roles in safety instrumented systems (SIS) where failure is not an option.

- 3009

In industrial automation, the TRICONEX 3009 is typically deployed within triple modular redundant (TMR) architectures to ensure continuous operation and real-time control of critical processes. It manages complex control logic and diagnostics, safeguarding personnel, equipment, and infrastructure by preventing hazardous conditions and system failures. Applicable in systems requiring real-time fault tolerance and deterministic control, this module is central to mission-critical environments worldwide.

Product Introduction & Positioning

The TRICONEX 3009 is a high-speed main processor module forming the core of Triconex’s safety and automation control systems. Powered by a Motorola MPC860 32-bit microprocessor running at 50 MHz, it features 16 MB DRAM and 32 KB SRAM to enable efficient execution of user-defined safety and control programs.

Designed to operate independently within a TMR platform, the processor supports fast communication via a high-speed TriBus communication interface capable of 25 Mbps data transfer with 32-bit CRC error checking to ensure data integrity. Each module contains its own clock, power regulator, and I/O handling capabilities, allowing it to perform independently yet synchronized in a redundant system.

The TRICONEX 3009 module is validated for seamless integration with TRICON v9.6 and higher firmware, with upgrade paths supporting online operation to avoid system downtime. It serves as the processing backbone in industries demanding certified safety compliance and real-time control precision.

Key Technical Features & Functional Benefits

The TRICONEX 3009 boasts triple modular redundancy architecture that guarantees continued operation even if one processor fails, eliminating single points of failure and elevating system availability. Its 16 MB DRAM facilitates handling large and complex control and safety applications.

The module supports event sequence recording (SOE), capturing precise timestamps of variable state changes crucial for forensic analysis and operational review. It also incorporates comprehensive diagnostic capabilities capable of detecting faults in memory, processors, I/O, and peripherals to enhance preventative maintenance.

Built for industrial robustness, the module operates within a broad temperature range and supports high-speed communication with I/O modules and external hosts via Ethernet, RS-232, and USB ports. This flexibility supports integration with SCADA, DCS, and other supervisory systems to ensure complete plant visibility.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | TRICONEX 3009 |

| Manufacturer | Triconex (ABB) |

| Processor | Motorola MPC860, 32-bit @ 50 MHz |

| Memory | 16 MB DRAM, 32 KB SRAM |

| Communication Bus | TriBus, 25 Mbps |

| Communication Ports | Ethernet, 2x RS-232, 1x USB |

| Event Sequence Recording | Supported |

| Operating Temperature | Industrial range |

| Dimensions (Approx.) | 45 x 20 x 15 cm |

| Weight | Approx. 3 kg |

| Firmware Compatibility | TRICON v9.6 and higher |

| Key Features | Triple modular redundancy, high-speed processing, extensive diagnostics |

Related Modules or Compatible Units

TRICONEX 3008 – Predecessor main processor module in the Tricon system line.

3501E / 3502E Input Modules – Digital input modules compatible with Triconex processors.

3601/3603 Digital Output Modules – Complementary output modules for process control.

BC800 – Bus interface module for communication with system I/Os.

3505 – Specialized analog input module for diverse signal handling.

Installation Notes & Maintenance Best Practices

Install the TRICONEX 3009 in control cabinets in accordance with manufacturer guidelines, ensuring stable power supply and secure communication cabling. Proper grounding and environmental control mitigate interference and thermal stress, preserving operational integrity.

Routine diagnostic checks using the module’s self-monitoring and SOE features support proactive fault detection. Firmware updates and system backups can be performed online, maintaining high availability. Physical inspections and cleaning enhance the longevity of connectors and cooling systems.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626