Description

What This Product Solves

In the unforgiving domain of safety instrumented systems, where a momentary lapse in control logic can escalate to process deviations or hazardous releases, engineers face the relentless pressure of ensuring fault-tolerant execution amid diverse field inputs and network demands. Legacy and modern DCS alike often struggle with single-threaded processors that falter under load spikes, leading to desynchronized events or delayed diagnostics in environments like offshore drilling rigs or nuclear cooling loops, where I/O signal integrity directly ties to human and asset safety. The Triconex 3008 tackles this as the enhanced main processor module in the Tricon TMR platform, delivering triple modular redundancy (TMR) to synchronize three independent computation channels, thereby upholding deterministic control without single points of failure.

This module is indispensable in high-integrity process control applications—imagine a gas compressor station modulating pressures via remote I/O, or a boiler safeguard sequence in power generation syncing across redundant chassis. Absent a TMR-capable brain like the Triconex 3008, setups contend with non-voted faults that obscure sequence-of-events (SOE) logging or drift in time-stamped alarms, amplifying mean time to repair and regulatory exposures under IEC 61508 SIL 3/4 mandates. It counters these by executing user programs in parallel across Motorola MPC860 cores, cross-validating outputs via hardware voting to achieve 10^-4 dangerous undetected failure rates, while the TriClock mechanism aligns timestamps to ±2 seconds/day, ensuring forensic accuracy in event reconstruction.

What distinguishes it in industrial automation is the blend of legacy compatibility with forward scalability: supporting Tricon v9.6 and later, it interfaces with Modbus slaves or Ethernet hosts without custom gateways, easing migrations from older Invensys systems. For reliability engineers vetting upgrades, the Triconex 3008 isn’t just a CPU—it’s a redundancy orchestrator that minimizes engineering overhead in I/O architectures, where high-reliability signal processing turns potential chaos into certified continuity. By embedding diagnostics like CRC-protected TriBus transfers at 25 Mbps, it empowers teams to sustain operations in the harshest nodes, mitigating the cascade risks of processor anomalies and aligning with the imperative for seamless, ever-watchful process governance in an era of escalating safety thresholds.

- 3008

- 3008

How the Product Works & Fits into a System

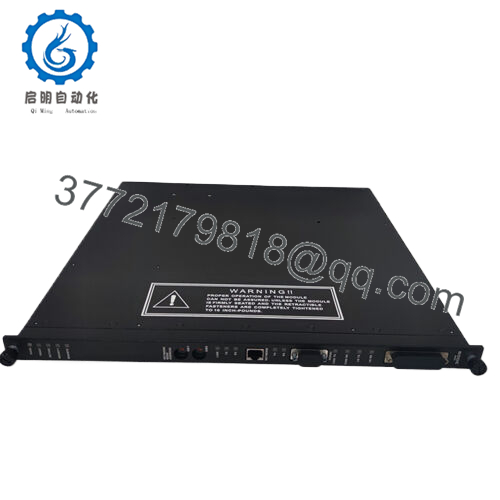

The Triconex 3008 embodies TMR at its core, housing three mirrored Motorola MPC860 processors—each a 32-bit, 50 MHz unit—that independently run the same control program, fetched from 6 MB Flash, before a dedicated voter circuit selects the median output for actuators or alarms, ensuring a single channel’s glitch doesn’t propagate. It juggles tasks like SOE capture from I/O modules or time sync via TriClock, distributing loads across 16 MB DRAM for runtime variables and 32 KB battery-backed SRAM for critical retains, all while the optically isolated RS-232 port streams diagnostics to TriStation 1131 development tools. Power draw remains lean at 24/48 V DC, with hot-spare provisions for online swaps that preserve system state without process interruption.

Positioned as the computational nexus in Tricon chassis, this module slots into the mainframe alongside I/O terminators and communication modules, linking via the high-speed TriBus for 32-bit DMA transfers that feed redundant paths, while Ethernet or serial ports bridge to upstream SCADA like DeltaV or 800xA. In a full TMR stack, three Triconex 3008 units form a simplex, duplex, or triplex configuration, with fiber optic interconnects for remote extension up to 1 km, enabling bumpless failover in under 10 ms during maintenance. It supports protocols like Modbus TCP for master/slave dialogues with field devices, offloading I/O polling to dedicated modules while the MP handles high-level sequencing, such as PID loops or burner management logic.

Diagnostics are proactive and layered: built-in self-tests poll memory parity and bus integrity every cycle, flagging discrepancies to the front-panel LEDs or event logger, accessible via the serial diagnostic channel for remote firmware pushes. For hybrid setups, it coexists with Trident legacy controllers, scaling from standalone safety loops to plant-wide SIS overlays without recoding. This central role—bridging field physics to supervisory analytics—accelerates response envelopes in safety-critical paths, shrugging off G3 harshness with conformal coatings, while the 500 V isolation on ports guards against ground shifts in shared cabinets. In essence, the Triconex 3008 doesn’t impose on your architecture; it reinforces it, fostering a voted harmony where redundant computations yield singular, trustworthy control.

| Specification | Details |

|---|---|

| Model Number | 3008 |

| Brand | Triconex (Schneider Electric) |

| Type | TMR Enhanced Main Processor Module |

| Input Voltage | 24 V DC or 48 V DC |

| Operating Temp Range | -40°C to +70°C (Class G3 harsh) |

| Mounting Style | Chassis Slot / Hot-Spare |

| Dimensions | 16 x 16 x 12 cm |

| Weight | 0.8 kg |

| Interface/Bus | TriBus (25 Mbps), RS-232, Ethernet |

| Compliance | IEC 61508 SIL 3/4, CE, RoHS |

| Supported Protocols | Modbus TCP/RTU, Profibus |

| Typical Power Draw | 10 W |

Real-World Benefits

Selecting the Triconex 3008 embeds a redundancy ethos that quietly averts the dominoes of failure, its TMR voting mechanism ensuring control outputs mirror fault-free precision even if one channel encounters cosmic ray-induced bit flips, which in flare gas recovery units translates to uninterrupted compression without spurious vents, often sustaining 99.999% availability that buffers against revenue dips from downtime. Operators in midstream facilities appreciate how the TriClock’s drift tolerance aligns SOE across nodes, enabling post-incident reconstructions that pinpoint root causes in minutes rather than hours, streamlining RCA sessions and fortifying insurance claims with timestamped veracity.

The module’s plug-in scalability trims integration tolls, hot-swapping into existing Tricon frames with auto-state transfer that collapses outage windows to under a shift, freeing commissioning crews for logic refinements over hardware wrestles. Its G3-rated resilience—vibration-proof mounts and wide thermal span—upholds DRAM refresh rates amid furnace glows or rig heaves, obviating frequent recalibrations that plague non-TMR peers and ensuring long-term performance tuned to 20-year asset lives. A European refinery upgrade, for one, halved diagnostic false positives by leveraging the 32 KB SRAM for retained fault buffers, redirecting maintenance budgets to predictive AI overlays on Modbus streams.

Deeper value emerges in empowered ecosystems: by offloading voted I/O to the MP, teams unlock richer TriStation analytics for what-if simulations, accelerating SIL proofs and easing turnover for control room staff through intuitive event hierarchies. This reduces engineering overhead via pre-vetted function blocks that scale from discrete safeties to analog loops, while the 6 MB Flash safeguards code against power-loss corruptions. For SIS architects balancing certification and agility, the Triconex 3008 yields more than compliance—it’s a dependability multiplier that recoups via slashed incident exposures, turning TMR from a mandate into a margin-maker in high-stakes flows.

Typical Use Cases

In oil and gas upstream, the Triconex 3008 anchors wellhead shutdown systems, where TMR processors vote on pressure transducer inputs to command valve closures amid subsea vibrations, its TriBus speed ensuring high-reliability I/O signals for SIL 3 interlocks in process control environments prone to H2S corrosion. Continuous uptime is non-negotiable here, with the module’s diagnostic port facilitating remote health polls during drilling campaigns.

Power generation plants deploy the Triconex 3008 in turbine overspeed protections, synchronizing three channels to monitor vibration and speed via remote I/O modules, engineered to endure boiler house heat for critical system uptime per ASME standards. Fast execution cycles under 10 ms support fast data cycles in used in power plants, where voted logic prevents turbine trips from single faults during grid excursions.

Chemical batch reactors leverage this processor for reaction inhibition sequences, aggregating discrete alarms from level switches in redundant chassis, its harsh-class tolerance shining in solvent-laced atmospheres for seamless process control. The Triconex 3008 excels in these modular setups, upholding IEC-compliant safeguards where input variances could ignite runaway reactions. Across extraction, energy, and processing, the Triconex 3008 fortifies TMR frameworks, thriving where redundancy meets the raw edge of operations.

Compatible or Alternative Products

Triconex 3009 – Enhanced variant with expanded Flash for larger control programs in v10+ systems.

Triconex 3501T – TMR digital input module for pairing with 3008 in discrete-heavy SIS loops.

Triconex 3604E – Analog output companion for voted actuator commands in process loops.

Triconex 3703E – Communication module add-on for Ethernet extensions in networked Tricon setups.

Triconex 3511 – Legacy main processor alternative for v9.x migrations with basic TMR.

Triconex 3615E – Relay output module for alarm integration alongside 3008 diagnostics.

Triconex 8310 – Chassis base for housing multiple 3008 modules in redundant frames.

Triconex 4201 – I/O bus interface for remote extensions in distributed safety architectures.

Setup Notes & Maintenance Insights

When racking the Triconex 3008 into a Tricon chassis, confirm slot parity across redundant frames—primary in slot 1, secondaries offset to avoid bus contention, and verify TriBus terminators at chain ends to cap reflections under 10 ns. Power budgeting is critical: allocate separate 24/48 V feeds per chassis with UPS tie-ins, and baseline the battery voltage at 3.6 V post-install to ensure SRAM holds through 72-hour outages; mismatches here can orphan retains during brownouts. Firmware alignment demands care—use TriStation to push matched loads across all three channels, validating CRCs to sideline sync drifts that mimic voted faults, and simulate I/O via the diagnostic port pre-live to tune scan rates against your loop dynamics.

Field tenure relies on disciplined audits that mesh with SIS proof tests, keeping the TMR triad vigilant sans full pulls. Monthly, interrogate the front LEDs for channel sync—uniform greens signal harmony, with isolated reds cueing a non-intrusive self-test via serial to log voter discords, often tracing to loose fiber LCs worth a 0.5 Nm retighten. Semiannually, cycle the hot-spare routine offline, confirming <5 ms state transfer while monitoring TriClock skew with a GPS reference—deviations over 1 second flag crystal swaps to preserve SOE fidelity. In dusty or humid bays, inspect conformal edges quarterly for cracks with a loupe, applying silicone sealant if needed, but mask vents to avoid thermal pockets during Flash burns. Harvest event buffers routinely over RS-232 for trend baselines, spotting load asymmetries that hint at program bloat for code diets. These pragmatic pulses, drawn from SIS war rooms, cast the Triconex 3008 as a self-sustaining sentinel, honing focus on process prowess over parity patrols.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626