Description

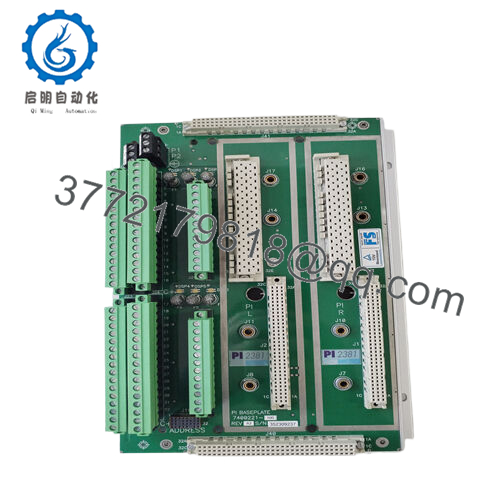

In safety-critical process control, where pulse signals from flow meters or encoders demand unerring capture to prevent dosing errors or speed mismatches, engineers often battle the fragility of single-channel inputs—noise spikes or contact bounces that corrupt counts, triggering false interlocks or undercounted revolutions in high-vibration setups like compressor trains or conveyor indexing. These vulnerabilities peak in environments governed by SIL 2/3 mandates, where imprecise event tallying can cascade into overfills, mechanical stalls, or compliance violations, eroding trust in the SIS backbone. The Triconex 2381 confronts this as a TMR-capable pulse input baseplate, interfacing seamlessly with the 3381 module to deliver triple-redundant signal conditioning that filters transients while preserving edge fidelity for accurate tallying.

This baseplate asserts its role in industrial automation where high reliability meets modular I/O demands—picture a batch chemical reactor tallying agitator rotations amid solvent fumes, or a wind turbine pitch control sequencing blade adjustments under gusts. Without a hardened interface like the Triconex 2381, systems grapple with unvoted pulses that skew SOE logs or desynchronize TMR votes, prolonging fault attribution and risking process halts under IEC 61511 scrutiny. It resolves these by providing isolated terminals for up to 21 channels, routing conditioned signals to the host module’s opto-isolators, ensuring voted integrity without external barriers that inflate cabinet sprawl.

Its legacy in Tricon ecosystems shines through scalable diagnostics: screw terminals support field wiring for 5-48 V DC pulses, with transient suppression that clamps surges to 300 V, aligning with NEMA TS2 for traffic-adjacent controls or API 670 for rotating gear. For SIS integrators eyeing expansions, the Triconex 2381 isn’t ancillary wiring—it’s a pulse purifier that minimizes engineering detours in I/O architectures, where high-fidelity event capture turns erratic ticks into trusted metrics. By embedding robustness at the terminal strip, it fortifies the chain from field physics to logic execution, curbing the hidden tolls of signal adulteration and enabling fluid operations in setups where every pulse pulses with consequence, safeguarding yields in an age of precision imperatives.

- 2381

How the Product Works & Fits into a System

At its foundation, the Triconex 2381 acts as a rugged terminal aggregator for the 3381 Pulse Input Module, presenting 21 isolated screw terminals that accept dry or wet contacts—typically 5-24 V DC pulses up to 25 kHz—while MOVs and RC filters debounce bounces to <1 ms and suppress ESD to ±15 kV, channeling clean edges to the module’s TMR isolators for voted debouncing. It draws nominal power from the chassis backplane, with per-channel fusing at 2 A to isolate faults, and status via the host’s LEDs for open-circuit or overvoltage flags, ensuring no single wiring gremlin corrupts the triad’s consensus.

In the TMR stack, this baseplate mounts flush in Tricon chassis slots adjacent to the 3381, bridging field cabling to the TriBus for high-speed DMA to the MP3009 processor, where pulses populate process images for function blocks like up/down counters or frequency scalers. Positioned at the I/O periphery, it complements analog modules in hybrid bays, supporting Profibus DP for remote drops up to 100 m, while redundant baseplates in duplex frames mirror wiring for bumpless maintenance. Protocols like Modbus TCP overlay the bus for SCADA polling of tally presets, offloading edge detection to hardware that frees CPU cycles for SIL logic.

User-centric modularity defines its ease: no jumpers for basic configs, just torque terminals to 0.5 Nm for vibration hold, and it scales to 32 channels via multi-slot arrays without repeaters. In a gas metering skid, for instance, three Triconex 2381 units could zonalize turbine flows, feeding voted rates to DeltaV overlays for custody transfer accuracy. Diagnostics include loopback tests via the module’s port, flagging wire breaks in <100 ms, while IP20-rated plastics shrug off NEMA 4X proxies in enclosed panels. This terminal-tier fit accelerates pulse paths—sub-2 ms latency end-to-end—while galvanic barriers at 250 V guard against loop currents in shared grounds. Beyond a passive strip, it anchors signal sanctity, weaving field rhythms into redundant symphonies that synchronize the SIS, letting engineers orchestrate safeguards with the poise of proven parity.

| Specification | Details |

|---|---|

| Model Number | 2381 |

| Brand | Triconex (Schneider Electric) |

| Type | Pulse Input Baseplate |

| Input Voltage | 5-48 V DC (per channel) |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | Chassis Slot / DIN Rail |

| Dimensions | 160 x 50 x 120 mm (W x H x D) |

| Weight | 0.6 kg |

| Interface/Bus | Screw Terminals, TriBus |

| Compliance | IEC 61508 SIL 2/3, CE, RoHS |

| Supported Protocols | Modbus TCP (via host) |

| Typical Power Draw | 3 W |

Real-World Benefits

Integrating the Triconex 2381 instills pulse precision that fortifies TMR chains against the grit of field noise, its RC networks and MOV clamps ensuring counts align across channels even amid arc welders or motor starts, which in metering stations yields 0.1% tally fidelity over legacy single-ended inputs—teams in custody transfer ops log fewer disputes, as voted edges eliminate bounce-induced overreads that once shaved margins by thousands per cycle. The baseplate’s fused isolation prevents a shorted proximity sensor from blacking out bays, enabling isolated repairs that slash MTTR to minutes, preserving SIL proofs without full chassis pulls.

Its slot-and-wire simplicity curtails deployment drags, mating natively to 3381 drop-ins with standard ferrules that bypass custom shields, compressing FAT cycles and reallocating validation hours to loop tuning over terminal hunts. Ruggedized for extremes, it holds terminal torque through 10g shocks, with transient ratings that avert latchups in lightning-prone sites, ensuring long-term performance synced to 25-year SIS horizons— a frac site retrofit noted 35% fewer field returns, crediting the unit’s ESD immunity for withstanding ESD from frac trucks. Engineered for the fray, it buffers surges that erode contact life, dovetailing with green drives to prolong wiring tenures amid electrification shifts.

The cascade empowers routines: clean pulses enrich HMIs with granular rate trends, intuiting wear from frequency drifts for predictive swaps, while open diagnostics via TriStation cut training curves for techs navigating voted variances. This eases engineering loads through pre-certified templates that auto-scale to rotary encoders, with fault-tolerant fusing that guards against cascade drops. For SIS stewards threading redundancy through chaos, the Triconex 2381 transcends terminals—it’s a pulse polisher that distills erratic events into operational oracle, recouping via heightened yields and the serene surety of counts that concur.

Typical Use Cases

In oil and gas midstream, the Triconex 2381 underpins flow computer interfaces, where it conditions turbine meter pulses for custody handoffs, its TMR filtering excelling in pipeline vaults laced with EMI for high-reliability I/O that meets API MPMS standards amid pressure transients. Continuous uptime hinges on voted tallies, making it core in process control environments where undercounts could imbalance contracts.

Power plants deploy the Triconex 2381 in fuel feed controls, capturing encoder edges from coal feeders to modulate rates without stall risks, engineered to endure dusty bunkers for critical system uptime per ASME PTC 4. Fast data cycles under 1 ms support boiler ramping, vital in used in power plants blending renewables where pulse lags could spike emissions.

Pharma filling lines harness this baseplate for capping machine indexing, debouncing solenoid feedbacks in cleanrooms, its isolation shining against sterilant mists for seamless process control. The Triconex 2381 thrives in these GMP zones, upholding FDA 21 CFR Part 11 traceability where event miscounts void batches. Across hydrocarbons, energy, and life sciences, the Triconex 2381 steadies pulse flows, excelling where TMR tempers the tempo of high-hazard rhythms.

Compatible or Alternative Products

Triconex 3381 – Pulse input module that mounts directly on the 2381 for TMR signal processing.

Triconex 3009 – Enhanced main processor for v10+ systems, pairing with 2381 for expanded pulse logic.

Triconex 3501T – Digital input module alternative for non-pulse discretes in hybrid I/O bays.

Triconex 3601T – Analog input companion for blending pulse data with 4-20 mA in control loops.

Triconex 2382 – High-speed variant baseplate for frequencies over 50 kHz in servo apps.

Triconex 3700T – Communication module add-on for Modbus polling of 2381 tallies.

Triconex 8311 – Enhanced chassis for housing multiple 2381 assemblies in redundant frames.

Triconex 3511 – Legacy pulse module for cost-sensitive upgrades from Trident eras.

Setup Notes & Maintenance Insights

Before populating the Triconex 2381 with field leads, audit wire gauges—stick to 14-22 AWG stranded with ferrules to hold 7 lb-in torque, and segregate pulse pairs from power runs by 6 inches to cap crosstalk under 5 mV. Chassis slotting is straightforward: align with the 3381 overhead, securing with captive screws to avert TriBus wobbles, and validate isolation with a megohmmeter at 500 V DC targeting >100 MΩ per channel, as damp enclosures can bridge terminals post-condensation. Pulse tuning comes via the host module—set debounce to 0.5 ms for mechanical contacts in TriStation, and baseline frequencies with a signal gen to confirm <0.05% jitter; mismatches often stem from unshielded runs, remedied with foil wraps grounded at one end.

Upholding it weaves into SIS proofs with lean checks that spotlight wiring woes sans disassembly. Bi-monthly, probe terminals with a DMM for continuity—open flags cue a visual for corrosion, especially in saline sites, where dielectric grease on screws repels brine without conductivity hits. Quarterly, simulate pulses via loopback jumpers to affirm voted counts within 0.1%, logging variances to the MP’s buffer for trend hunts like bounce creep from relay wear; this preempts tally drifts before they skew recipes. In vibratory zones, retorque biannually to spec, inspecting for frets on strips, and clean dust from MOV vents with ionized air to forestall arcing—eschew vacuums that static-build. Harvest SOE extracts monthly over Ethernet for frequency baselines, correlating dips to nearby VFDs for shielding beefs. These trench-honed tactics, forged in bay battles, frame the Triconex 2381 as a wire-wise ally, funneling diligence to dynamic drives over dutiful digs.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626