Description

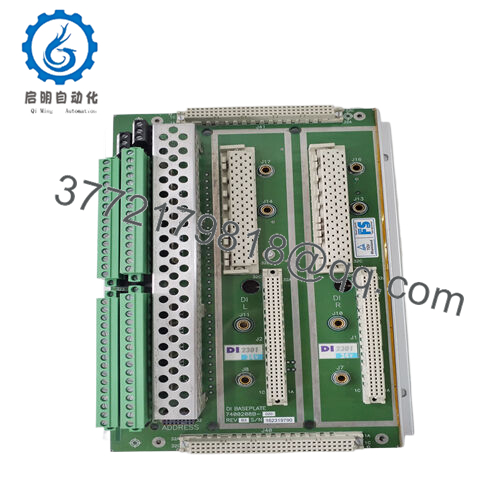

TRICONEX 2301 is a high-performance module that serves as the cornerstone of safety critical industrial control systems. It is an important component of the Triconex product family, which is renowned for its reliability in the field of industrial automation.

2301

Functionally speaking, the TRICONEX 2301 can serve as a discrete input module in many systems. Its main function is to accurately monitor and process digital signals. It serves as the “eyes” and “ears” of the control system, collecting data from various sensors and devices in the industrial environment. Then, these data are transmitted to the central control unit for further processing and decision-making.

In terms of system compatibility, TRICONEX2301is designed for seamless integration with various industrial control systems. It can be integrated into larger Safety Instrumented Systems (SIS) or used for Distributed Control Systems (DCS). Its modular design facilitates installation in the system architecture. For example, in complex industrial plant control systems, the TRICONEX2301 can be inserted into the control cabinet along with other modules to form a network that ensures overall safety and efficient operation.

2301

Main features and advantages:

In terms of functional performance, it has excellent signal processing speed. It can quickly detect and respond to changes in input signals, ensuring that the control system can respond in real-time. For example, in high-speed manufacturing processes, instant decision-making is crucial, and the TRICONEX 2301 can quickly transmit information about product quality or machine performance, enabling immediate corrective measures to be taken.

Its stability is another major advantage. TRICONEX2301is designed to withstand common voltage fluctuations and electrical noise in industrial environments, ensuring stable operation. This is crucial for maintaining the integrity of the control system, as unstable signal readings may lead to erroneous operations. It also has high fault tolerance, thanks to advanced algorithms that can filter out false signals and correct minor data failures.

The hardware design of TRICONEX 2301is sturdy and durable. It is made of advanced materials and can withstand extreme temperatures ranging from -40 ° C to+70 ° C. This makes it suitable for both cold outdoor installation environments such as Arctic oil fields and hot industrial environments such as steel plants. Its compact size is also an advantage, making it easy to install in the narrow space inside the control cabinet. This module usually adopts the standard DIN rail installation method, which simplifies the installation process and ensures a firm installation.

In terms of compatibility, TRICONEX2301 supports multiple communication protocols, including Modbus. This enables it to smoothly connect with various other devices and systems in industrial networks. Whether connected to different types of sensors, actuators, or other control modules, TRICONEX2301 can establish reliable communication links and achieve seamless data exchange.

Long term reliability is also a major advantage of the TRICONEX2301. It has good thermal efficiency, which means it can effectively dissipate heat during continuous operation. This not only helps maintain stable performance, but also extends the lifespan of the module. In industrial applications that require equipment to operate continuously for extended periods of time, the reliability of the TRICONEX 2301 ensures minimal downtime and lower maintenance costs.

2301

Technical specifications:

Model 2301

Brand Triconex

Type Discrete Input Module

Power supply 12-36 VDC

Maximum input current per channel is 50 mA

Input quantity 16

Signal type number

Working temperature -40 ° C to+70 ° C

Installation method: DIN rail

Interface communication interface: Modbus RTU

Certified CE, UL, CSA, ATEX

Natural convection for heat dissipation

The environmental grade is suitable for harsh industrial environments and has high dust, moisture, and vibration resistance capabilities

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

2301

Application areas:

In the oil and gas industry, facilities such as refineries and natural gas processing plants are always threatened by flammable and explosive substances. Here, TriconeX 2301 plays a crucial role. It is integrated into the Safety Instrumented System (SIS) for monitoring critical parameters. For example, it closely monitors the pressure level inside the pipeline. Once the pressure exceeds the safe range, the TRICONEX 2301 can quickly trigger an emergency stop (ESD) to prevent potential disasters such as explosions or leaks. In chemical plants, complex chemical reactions are constantly occurring. This module is used to control and monitor the flow of reactants, ensuring that the chemical process remains within the required parameter range, maintaining product quality, and preventing dangerous chemical imbalances.

Whether it is coal-fired power plants, nuclear power plants, or renewable energy facilities, power plants all rely on TRICONEX 2301 to achieve stable operation. It is responsible for managing the synchronization of generators, ensuring stable power output and compatibility with the grid. In remote mining operations, equipment continues to operate under harsh conditions, and the TRICONEX 2301 is a component of the control system used to monitor the performance of heavy machinery such as excavators and conveyors. By promptly detecting any faults, it helps reduce downtime and maintain production efficiency.

Related products:

TriconeX 3720- A high-performance processor module in the Triconex family. It works well with TRICONEX 2301 and can efficiently process the data received from the 2301 module, enabling complex control operations in industrial systems.

TRICONEX 4351B – A communication module that enhances the connectivity of TRICONEX 2301. It allows for broader network integration, enabling 2301 to communicate with more devices through different industrial protocols.

TRICONEX 8311- a discrete output module that complements the input functionality of TRICONEX 2301. 2301 reads digital signals, while 8311 can be used to send digital control signals based on data processed by 2301 and other components in the system.

TRICONEX 9361- An analog input module. In industrial applications that require simultaneous processing of digital and analog data, the TRICONEX 2301 (for digital input) and 9361 (for analog input) can work together to provide a comprehensive data acquisition solution for control systems.

TRICONEX 1501A – A power module compatible with TRICONEX 2301. It ensures stable and reliable power supply for the 2301 module, which is crucial for its continuous operation in industrial environments.

TRICONEX 2704- A relay output module that can be used in conjunction with TRICONEX 2301. The input data of 2301 can trigger the 2704 switching circuit, thereby achieving control of various industrial equipment.

TRICONEX 3008- Another processor module, but with different processing capabilities compared to 3720. It can be used in scenarios where TRICONEX 2301 needs to be integrated into systems with specific processing requirements, providing another option for system configuration.

Installation and maintenance:

Before installing TRICONEX 2301, several pre installation considerations need to be taken into account. Firstly, it is necessary to carefully evaluate the size of the control cabinet. TRICONEX 2301 has specific dimensions and must ensure sufficient space for proper installation and future maintenance access. Adequate clearance needs to be left around the module to ensure proper ventilation. In industrial environments, heat accumulation can be a serious issue, and proper ventilation can help maintain the optimal operating temperature of modules.

Grounding is another key aspect. TRICONEX 2301should be properly grounded to prevent surges and ensure accurate signal readings. Poor grounding connection may cause signal interference and abnormal module behavior. It is recommended to strictly follow the manufacturer’s guidelines to establish grounding connections.

In terms of maintenance, it is recommended to conduct regular visual inspections. Check for any signs of physical damage, such as cracked casing or loose connections. In normal industrial environments, these inspections should be conducted at least once a month, but more frequently in harsh or high vibration environments. Regular signal diagnosis should also be conducted. This involves using appropriate testing equipment to verify whether the module accurately reads the input signal. If any differences are found, further inspection of the sensor connections or internal components of the module may be necessary.

Other product models of TRICONEX:

Triconex 3009

Triconex 3624

TRICONEX 3625

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONEX 3721

Triconex 3807

TRICONEX 8111

TRICONEX 8310

TRICONEX 3721

TRICONEX 3624

TRICONEX 3704E

TRICONEX 3564

TRICONEX 4329

TRICONEX 3700A

TRICONEX 3503E

TRICONEX 3006

TRICONEX 8110

TRICONEX 3721

TRICONEX 8310

TRICONEX RXM4200-3

TRICONEX RXM4201

TRICONEX 3624

TRICONEX 4000094-350

TRICONEX 4000103-546

TRICONEX 4000103-550

TRICONEX 4000093-346

TRICONEX 8310

TRICONEX 8110

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626