Description

Real-World Use & Application Scenarios

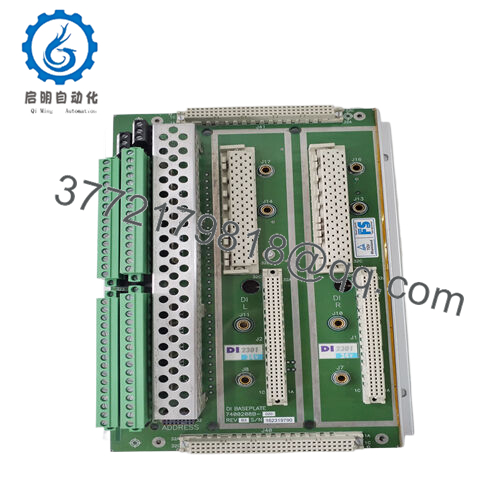

The TRICONEX 2301 digital input module is an integral part of safety instrumented systems used across industries such as oil and gas, chemical processing, power generation, and manufacturing. It is designed to reliably acquire and process discrete digital signals from field devices including switches, sensors, and safety interlocks, facilitating the monitoring of critical process variables for real-time safety management.

In industrial automation, the module supports operational safety by ensuring that critical inputs—such as emergency stop commands or process alarms—are accurately captured and transmitted to the main processor for swift response. Its fault-tolerant design and high diagnostic coverage make it suitable for redundant triple modular redundancy (TMR) systems where unquestionable reliability is essential.

The TRICONEX 2301 is applicable wherever rigorous safety standards are mandated, enabling systems to detect and act upon digital input signals to prevent accidents, equipment damage, and ensure personnel safety.

Product Introduction & Positioning

The TRICONEX 2301 is a 24-point digital input baseplate designed to interface with the TRICONEX safety platform. Its primary function is to collect and condition discrete input signals from the plant floor for processing by the Tricon processor modules.

Positioned for high diagnostic safety and fault tolerance, the module features isolated input channels to prevent cross-channel interference and supports a wide input voltage range of -30 VDC to +30 VDC configurable to various field conditions. It operates with a fast response time of approximately 50 ms per channel, ensuring timely data acquisition for safety decisions.

The module is built for easy integration within TRICONEX’s triple modular redundant architecture, supporting hot swapping and online replacement without system interruption, thus enhancing system availability.

- 2301

Key Technical Features & Functional Benefits

The TRICONEX 2301 offers 24 discrete, isolated digital input points designed to meet rigorous safety instrumented system requirements. Its diagnostic coverage exceeds 99%, enabling early detection of faults and minimizing risks of dangerous failures.

The module features wide input voltage compatibility, accommodating TTL and CMOS level signals, with maximum input current per channel capped at 6 mA, minimizing power consumption and prolonging device life. Its robust design supports operation over broad temperature ranges from -40°C to +70°C, maintaining reliability in harsh environments.

Enhanced diagnostics, built-in redundancy, and clear LED status indicators simplify maintenance and troubleshooting. The module’s isolated inputs prevent failure propagation, ensuring high system integrity.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | TRICONEX 2301 |

| Brand | Triconex (ABB) |

| Product Type | Digital Input Module |

| Number of Input Channels | 24 Discrete Inputs |

| Input Voltage Range | -30 VDC to +30 VDC |

| Maximum Input Current | 6 mA |

| Response Time | 50 ms per channel |

| Diagnostic Coverage | >99% |

| Operating Temperature Range | -40°C to +70°C |

| Compliance | IEC 61508 SIL 3 Certified |

| Isolation | Channel-to-channel isolated |

| Dimensions (Approx.) | Standard Triconex module size |

Related Modules or Compatible Units

TRICONEX 2401 – Digital output module complementing the 2301 input module.

TRICONEX 3009 – Main processor module for central control and safety logic processing.

3501E / 3502E Modules – Additional input channel modules compatible with TRICONEX systems.

BC800 – Bus control module facilitating communication in Triconex racks.

3505 – Analog input module for expanded processing of continuous signals.

Installation Notes & Maintenance Best Practices

Installation of the TRICONEX 2301 involves mounting within a compatible rack system with proper grounding and shielding according to ABB guidelines to maintain signal fidelity. The module supports hot swapping for easy replacement without system downtime.

Routine maintenance focuses on verifying LED status lights, performing diagnostics using Triconex tools, and ensuring firmware is up to date. Periodic cleaning and connection checks extend the module’s lifespan and preserve system safety integrity.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626