Description

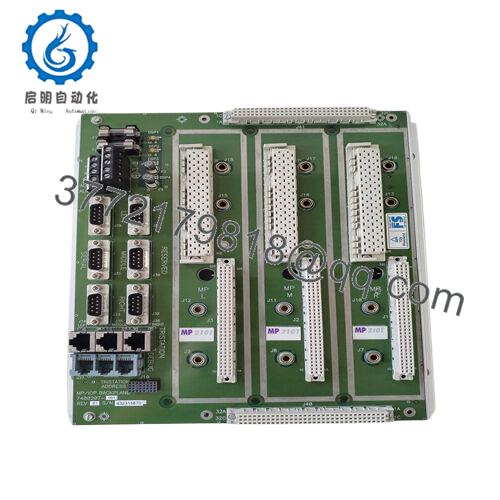

The Triconex 2101 is a high-performance, high reliability processor module in the Triconex product line, which enjoys a high reputation in safety critical industrial control systems. It is designed as the core component of safety instrumented systems, providing necessary computing and decision-making capabilities to quickly and accurately respond to potential hazardous situations.

2101

The Triconex2101 acts as the “brain” in the overall architecture of the security system, processing input signals from a large number of sensors. These sensors can detect variables such as temperature, pressure, liquid level, as well as equipment status (such as valve opening/closing, motor running/stopping). Based on preset logic and algorithms, Triconex2101then generates output signals to control actuators, which can shut down equipment, activate emergency systems, or adjust process parameters to maintain safe operating conditions.

2101

Main features and advantages:

One of the most notable features of Triconex2101 is its Triple Redundancy (TMR) architecture. In TMR configuration, the module has three independently running processing channels. Each channel processes the same input data simultaneously. Then, the voting logic circuit compares the results of these three channels. If two or more channels produce the same result, then that result is considered the correct output. This TMR architecture provides high error tolerance. For example, if a component in one channel fails, the other two channels can continue to function normally, and the voting mechanism ensures that the overall system output remains accurate. This greatly reduces the probability of system failure caused by component failures and improves the reliability of safety critical applications.

The Triconex 2101 also has high-speed processing capabilities. It can quickly analyze large amounts of input data from sensors and execute complex control algorithms in real-time. In industrial processes, the millisecond difference may determine whether a safe shutdown or a major accident occurs, so this fast processing speed is crucial. For example, in a high-speed chemical reaction process, if there is a sudden change in reaction kinetics that could lead to an explosion, Triconex 2101 can quickly detect this change, process the relevant data, and initiate appropriate safety measures such as transferring reactants or initiating emergency cooling before the situation worsens.

In terms of communication capabilities, the Triconex 2101 supports multiple industry standard communication protocols, including Ethernet, Modbus, and Profibus. This allows it to seamlessly integrate with other components of industrial control systems, such as distributed control systems (DCS), human-machine interfaces (HMI), and other safety related devices. It can easily exchange data with these systems, enabling operators to monitor and control safety critical processes from a central location. In addition, the ability to communicate with multiple devices simplifies system expansion and upgrades, as new sensors or actuators can be added to the system without undergoing large-scale redesigns.

This module is designed to be sturdy and reliable, capable of operating in harsh industrial environments. It can withstand high levels of electrical noise, vibration, and temperature fluctuations commonly found in industrial plants. This robust design ensures that the Triconex2101 can continue to operate reliably even under the harshest conditions, providing continuous protection for industrial processes.

2101

Technical specifications:

Model 2101

Brand Triconex

Type processor module

Working temperature -40 ° C to 85 ° C

Installation method: DIN rail installation

Ethernet interface Modbus、Profibus

Triple Redundancy (TMR)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

2101

Application areas:

In the oil and gas industry, the Triconex 2101 is often deployed in Safety Instrumented Systems (SIS) due to the potential for catastrophic accidents caused by process failures. It is an important component of the Emergency Shutdown (ESD) system. For example, on an offshore oil drilling platform, if a gas leak, high pressure, or fire is suddenly detected, the Triconex 2101 based ESD system will quickly and accurately execute the preset shutdown procedure. This ensures that all critical equipment, such as pumps, compressors, and valves, can be safely shut down, preventing the escalation of potential disasters and protecting personnel and the environment.

Chemical plants also heavily rely on Triconex 2101. These factories handle hazardous chemicals and involve complex chemical reactions. Triconex2101 is used to control and monitor process flows to prevent dangerous situations such as uncontrolled reactions and chemical leaks. In a large petrochemical plant producing plastics, the SIS integrated with Triconex 2101 can continuously monitor parameters such as temperature, pressure, and flow rate in the reactor. If any parameter deviates from the safe operating range, the system can immediately take corrective measures, such as adjusting the cooling water flow rate, cutting off the reactant feed, or activating the emergency ventilation system.

Power plants, whether coal-fired, gas turbine, or nuclear, utilize the Triconex 2101to enhance operational safety and reliability. In nuclear power plants, the consequences of system failures can be extremely serious, and Triconex2101 is part of the safety related control system. It monitors key parameters such as reactor core temperature, coolant level, and radiation level. Once an abnormal situation occurs, it can initiate an emergency cooling program, insert control rods to regulate the nuclear reaction, and isolate the affected area to prevent a nuclear accident from occurring.

Installation and maintenance:

Before installing Triconex 2101 it is necessary to carefully plan the installation location. This module should be installed in a control cabinet or cabinet that provides protection against dust, moisture, and physical damage. Ensure that the cabinet has sufficient ventilation to prevent overheating, especially considering the operating temperature range of the modules.

Verify whether the power supply meets the specified requirements. Check the voltage, current capacity, and power quality to ensure stable operation. Proper grounding is also crucial. Connect the grounding terminal of the module to a reliable ground wire to prevent electrical surges and interference.

During installation, carefully connect the module to other components such as I/O modules and communication cables according to the manufacturer’s instructions. Ensure that all connections are secure and properly terminated to avoid signal loss or intermittent faults.

For maintenance, it is recommended to conduct regular visual inspections. Check for signs of physical damage, such as cracks in the casing, loose connections, or signs of overheating. Regularly use built-in diagnostic functions or external diagnostic tools for diagnostic testing. These tests help identify potential issues before they lead to system failure.

Keep the firmware of the module updated. Schneider Electric regularly releases firmware updates, which may include bug fixes, performance improvements, and enhanced features. Carefully follow the official update procedure to ensure smooth and successful updates.

Other product models of TRICONEX:

Triconex 3009

Triconex 3624

TRICONEX 3625

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONEX 3721

Triconex 3807

TRICONEX 8111

TRICONEX 8310

TRICONEX 3721

TRICONEX 3624

TRICONEX 3704E

TRICONEX 3564

TRICONEX 4329

TRICONEX 3700A

TRICONEX 3503E

TRICONEX 3006

TRICONEX 8110

TRICONEX 3721

TRICONEX 8310

TRICONEX RXM4200-3

TRICONEX RXM4201

TRICONEX 3624

TRICONEX 4000094-350

TRICONEX 4000103-546

TRICONEX 4000103-550

TRICONEX 4000093-346

TRICONEX 8310

TRICONEX 8110

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626