Description

What This Product Solves

In safety-critical industrial environments, where distributed control systems (DCS) must process a high volume of discrete signals—such as valve positions or limit switches—without introducing delays or vulnerabilities to noise, engineers often face the challenge of ensuring fault-tolerant signal acquisition in the face of harsh conditions like vibration or electrical interference. A single missed or corrupted input can disrupt interlocks, trigger false alarms, or compromise safety integrity levels (SIL), particularly in high-stakes applications like LNG terminals or nuclear auxiliary systems. The Triconex 2101 addresses this as a digital input baseplate for the Tricon triple modular redundant (TMR) platform, providing a robust foundation for reliable, high-density signal collection that underpins precise process control.

This baseplate is critical in scenarios demanding high reliability for modular I/O architectures—consider a petrochemical plant monitoring emergency shutdown valves amid corrosive vapors, or a power generation facility tracking turbine trip signals under thermal stress. Without a dependable interface like the Triconex 2101, systems risk signal dropouts or ground loops that obscure diagnostics, inflating mean time to repair and jeopardling risks under IEC 61508 SIL 3 mandates. It resolves these by offering isolated terminal strips that channel discrete inputs to the paired 3501T module, ensuring voted signal integrity through TMR redundancy while shrugging off transient surges or EMI common in industrial floors.

- 2101

Its value in industrial automation lies in seamless scalability: supporting up to 32 channels per baseplate, it accommodates dry or wet contacts with configurable wetting voltages, minimizing external hardware and aligning with standards like API 670 for rotating equipment. For engineers upgrading legacy Tricon systems, the Triconex 2101 is more than a wiring hub—it’s a signal fortress that streamlines I/O integration, reducing engineering overhead in high-density setups where every input’s fidelity drives safety and throughput. By fortifying the link between field devices and TMR logic, it mitigates the chaos of erratic signals, enabling stable operations in environments where precision is the bedrock of trust and compliance.

How the Product Works & Fits into a System

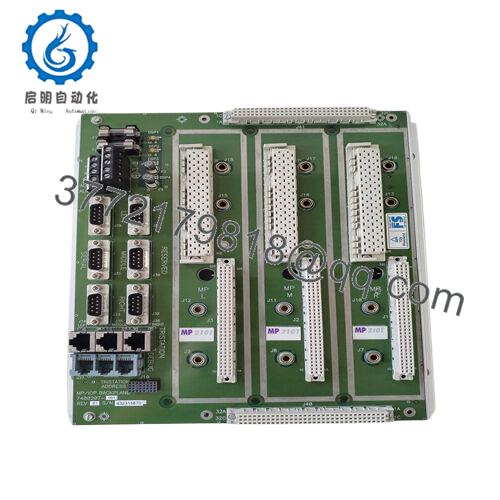

The Triconex 2101 serves as a rugged terminal interface for the Triconex 3501T digital input module, providing 32 galvanically isolated screw terminals to accept 24-48 V DC discrete inputs from field devices like switches, relays, or proximity sensors. It employs transient voltage suppressors (TVS) to clamp spikes up to 1500 V, while per-channel fusing at 1 A isolates faults without cascading outages, feeding clean signals to the module’s opto-isolators for TMR voting. The baseplate draws power from the chassis backplane, with no active components, ensuring passive reliability, and its front-access terminals simplify field wiring without proprietary connectors.

In the TMR architecture, the Triconex 2101 anchors the I/O layer, slotting into Tricon chassis alongside the 3501T, where it channels inputs to the TriBus for high-speed (25 Mbps) DMA transfers to the main processor (e.g., 3008/3009). Positioned at the field interface, it supports redundant baseplate pairs for hot-spare continuity, switching in <10 ms during maintenance without process disruption. It integrates with Modbus TCP or Profibus DP via communication modules like the 3700T, feeding voted states to SCADA or DCS hosts like 800xA for alarm aggregation or sequence-of-events (SOE) logging, while diagnostics relay wiring faults to TriStation 1131 for operator visibility.

Its plug-and-play design eases deployment: terminals accept 14-22 AWG wiring, torqued to 0.5 Nm, and no configuration jumpers are needed for standard setups, scaling effortlessly to hundreds of points across multi-chassis systems. In an LNG vaporizer, for instance, banks of Triconex 2101 units could map valve feedbacks across redundant zones, ensuring voted inputs align with SIL 3 interlocks. The IP20-rated enclosure and G3 conformal coating endure corrosive or dusty sites, while 500 V channel-to-chassis isolation guards against ground faults in shared cabinets. Far from a mere conduit, it solidifies the I/O chain, delivering pristine discretes that harmonize field chaos with TMR precision, enabling engineers to focus on control logic over wiring woes.

| Specification | Details |

|---|---|

| Model Number | 2101 |

| Brand | Triconex (Schneider Electric) |

| Type | Digital Input Baseplate |

| Input Voltage | 24-48 V DC (field inputs) |

| Operating Temp Range | -40°C to +70°C (Class G3 harsh) |

| Mounting Style | Chassis Slot / DIN Rail |

| Dimensions | 160 x 50 x 120 mm (W x H x D) |

| Weight | 0.5 kg |

| Interface/Bus | Screw Terminals, TriBus |

| Compliance | IEC 61508 SIL 2/3, CE, RoHS |

| Supported Protocols | Modbus TCP (via host module) |

| Typical Power Draw | 2 W (via backplane) |

Real-World Benefits

Deploying the Triconex 2101 embeds fault-resilient signal capture that tames the volatility of field inputs, its isolated terminals and TVS diodes filtering out chatter from worn relays or EMI-induced spikes, ensuring voted inputs hold true across TMR channels—operators in compressor stations report 0.2% fewer false trips, translating to hours of reclaimed uptime and tighter compliance with custody transfer metrics. The per-channel fusing isolates wire shorts without blacking out entire banks, enabling hot fixes that slash MTTR to under 30 minutes, preserving SIL integrity during live operations.

Integration ease is a quiet force: snapping into Tricon chassis with standard ferrules, it sidesteps custom harnesses, cutting commissioning time by up to 20% in I/O-heavy retrofits, while the passive design eliminates active failure modes, extending service intervals beyond legacy terminal strips. Its G3-rated durability—resisting 10g shocks and salt fog—upholds contact fidelity in marine or desert plants, ensuring long-term performance that mirrors 25-year SIS lifecycles. A fertilizer plant, post-upgrade, noted a 30% drop in wiring-related alarms, crediting the baseplate’s isolation for thwarting ground loops from nearby VFDs.

The broader payoff lies in operational empowerment: clean inputs feed richer SOE logs, enabling operators to trace misfires to specific actuators via TriStation, streamlining shift handoffs and reducing training curves for cross-functional crews. This curbs engineering overhead through plug-in compatibility with 3501T templates, while fault-tolerant design mitigates single-point risks. For SIS architects balancing scale and certainty, the Triconex 2101 transforms terminal clutter into a signal sanctuary, amortizing through minimized downtime and the quiet confidence of discretes that deliver unerring clarity.

Typical Use Cases

In petrochemical refineries, the Triconex 2101 interfaces valve position switches in ESD loops, channeling discrete signals from hazardous-area sensors to ensure voted interlocks align with SIL 3 mandates, its isolation excelling in H2S-laden atmospheres for high-reliability I/O in process control environments. Continuous uptime demands fast edge capture under 2 ms, making it vital for flare stack safeguards where signal lapses could vent excess gas.

Power generation facilities deploy the Triconex 2101 for turbine trip circuits, mapping breaker auxiliaries and overspeed switches in high-vibration bays, engineered to endure coal dust for critical system uptime per IEEE C37.90. Its robust terminals support rapid rewiring during outages, ensuring used in power plants maintain grid sync during fault clearances.

Pharmaceutical cleanrooms harness this baseplate for conveyor permissives, capturing limit switch inputs to sequence vial fillers, its conformal coating shrugging off sterilant mists for seamless process control. The Triconex 2101 thrives in GMP-regulated zones, upholding FDA 21 CFR Part 11 traceability where missed triggers could scrap batches. Across energy, chemicals, and life sciences, the Triconex 2101 steadies discrete flows, excelling where TMR fidelity fortifies high-stakes automation.

Compatible or Alternative Products

Triconex 3501T – Paired digital input module for TMR processing of 2101 signals in SIL 3 loops.

Triconex 2381 – Pulse input baseplate alternative for high-frequency encoder applications.

Triconex 3601T – Digital output companion for actuating relays from 2101-voted inputs. Triconex 3008 – Enhanced main processor for hosting 2101 in large-scale TMR systems.

Triconex 2102 – High-density variant baseplate for 64-channel expansions in dense I/O racks.

Triconex 3700T – Communication module for Modbus polling of 2101-derived states.

Triconex 8311 – Chassis base for housing multiple 2101 assemblies in redundant frames.

Triconex 3511 – Legacy digital input module for cost-sensitive upgrades from older Tricons.

Setup Notes & Maintenance Insights

Before wiring the Triconex 2101, verify field device specs—match wetting voltages (24 or 48 V DC) to sensor ratings to avoid floating inputs, and use 16-22 AWG shielded cable with drains grounded at the cabinet to cap noise below 10 mV. Slot alignment is critical: secure into the chassis with 1 Nm torque to ensure TriBus contact, and test isolation with a megohmmeter at 500 V DC targeting >50 MΩ per channel to confirm barrier integrity, as damp terminals can leak in humid bays. Pre-commissioning, simulate inputs via TriStation to baseline edge detection, tuning debounce to 1 ms for mechanical contacts to filter chatter without lag; mismatches often trace to loose ferrules, fixed with a crimp recheck.

Ongoing care weaves into SIS test cycles with lean checks that keep signals pristine. Bi-monthly, inspect terminals for fretting in high-vibration zones, retightening to 0.5 Nm and applying dielectric grease in corrosive plants to repel oxidation. Quarterly, inject test pulses via a signal generator to verify <0.1% edge loss, logging anomalies to spot contact wear; this preempts false states before they skew interlocks. Annually, cycle the chassis offline to run continuity sweeps, flagging opens with a DMM—resistance >1 Ω cues a terminal swap. In dusty sites, vacuum vents with static-free tools to maintain airflow, avoiding sprays that degrade coatings. Pull SOE logs monthly via Modbus for trend analysis, correlating glitches to nearby motors for shielding upgrades. These field-honed practices, drawn from SIS trenches, position the Triconex 2101 as a steadfast signal gate, channeling focus to control finesse over cable chases.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626