Description

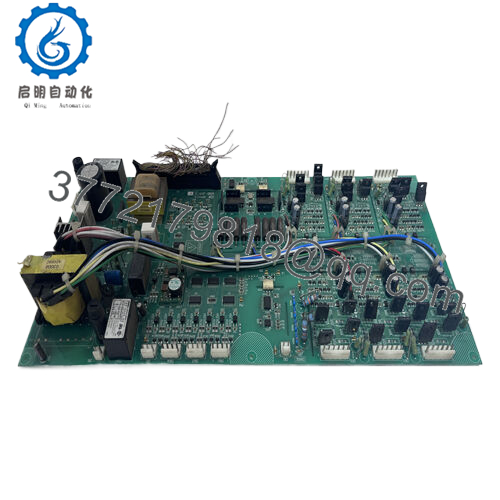

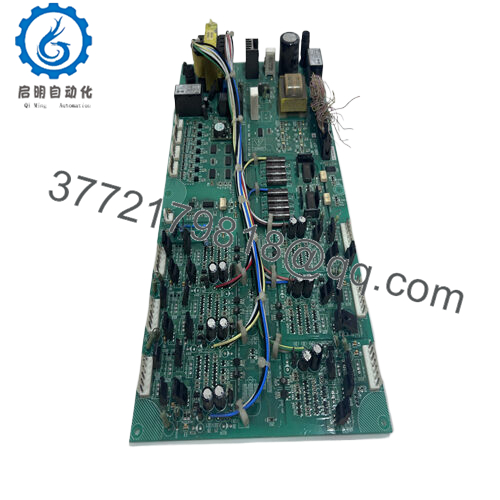

The TOSHIBA ARND-3119 A6 2N3A3119-B is a cost – efficient I/O and control module that can be seamlessly integrated into various industrial automation architectures. It acts as a fundamental building block, connecting field sensors and actuators to the central control unit, facilitating the flow of data within the automation stack. The module interfaces with common control platforms and backplane systems, supporting essential industrial communication protocols such as Modbus RTU, which allows for easy connection with a diverse range of equipment.

ARND-3119 A6 2N3A3119-B

Despite its affordability, the TOSHIBAARND-3119 A6 2N3A3119-B is equipped with basic yet reliable processing capabilities. It can analyze incoming signals, perform basic signal conditioning to ensure data integrity, and transmit information accurately. Its built – in status monitoring features provide engineers with visibility into the module’s operation, allowing for quick identification of any potential issues. While it may not have all the advanced features of high – end modules, it offers a solid foundation for automation tasks, and its simplicity makes it easy to maintain and troubleshoot within existing systems.

ARND-3119 A6 2N3A3119-B

Technical specifications:

Model NumberARND-3119 A6 2N3A3119-B

BrandTOSHIBA

TypeCost – efficient I/O and Control Module

Operating Temp Range-10°C to 55°C

Mounting StyleDIN Rail Mount

Interface/BusRS – 485

ComplianceCE, RoHS

Supported ProtocolsModbus RTU

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

ARND-3119 A6 2N3A3119-B

Main features and advantages:

Application areas:

ARND-3119 A6 2N3A3119-B

Related products:

- TOSHIBA 2N3A3120-B – An upgraded version with more advanced processing capabilities and additional features, suitable for applications requiring higher performance.

- TOSHIBA 2N3A3118-B – A more compact variant with similar basic functionality, ideal for installations with limited space.

- TOSHIBA ARND-3120 A6 2N3A3120-B – Offers enhanced diagnostic features and support for additional communication protocols, suitable for more complex automation systems.

- TOSHIBA 2N3A3117-B – A cost – optimized alternative with slightly reduced functionality, suitable for very budget – conscious projects where basic I/O control is sufficient.

- TOSHIBA ARND-3118 A6 2N3A3118-B – Has improved power efficiency and is designed for applications where energy consumption is a concern.

- TOSHIBA 2N3A3121-B – Provides higher data processing speed and is suitable for applications that require real – time data handling and quick response.

- TOSHIBA ARND-3121 A6 2N3A3121-B – Features advanced security features for data protection, making it suitable for applications where data integrity is critical.

Installation and maintenance:

TOSHIBA UTLH21

TOSHIBA GPF611**S

Toshiba CPUX01-01

TOSHIBA ARND-3119 A6 2N3A3119-B

Toshiba HCV-5HA

TOSHIBA BU643D

TOSHIBA GBU648E*S

TOSHIBA HC422B 7862 2N3B2895-C5 N-300

Toshiba PF612

TOSHIBA PU662

Toshiba SN626

TOSHIBA USIO21

Toshiba USIO21

Toshiba HCV-5HA

Toshiba TKKH-FBK21

Toshiba DPHC06G001

Toshiba SSLWO1G001

Toshiba MIF WO1G021

Toshiba AICWO1G022

Toshiba DICW01G031

Toshiba AIGW01G015

Toshiba LBIW01G021

Toshiba FDCW01G001

Toshiba AOCW01G022

Toshiba CPUX01G001

TOSHIBA AFX-90L-RH

TOSHIBA DOCW01G031

Toshiba I0WB01G021

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626