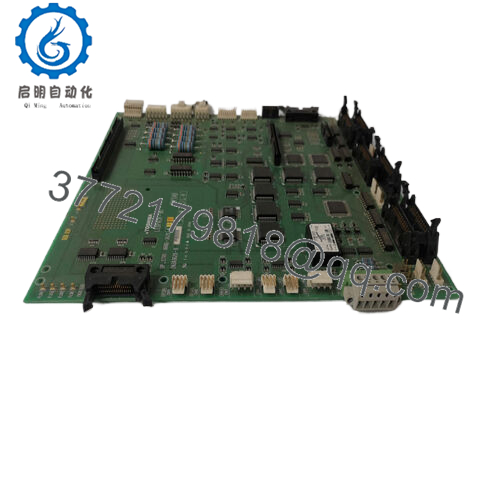

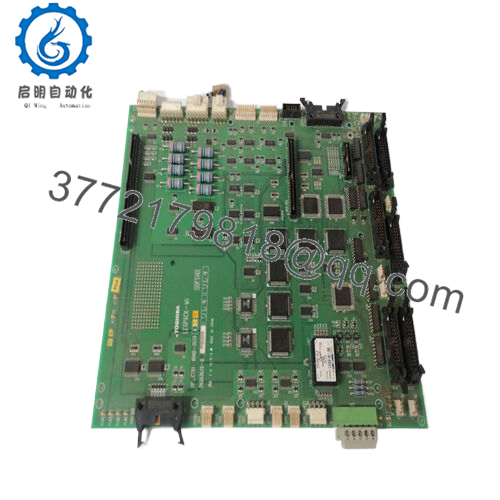

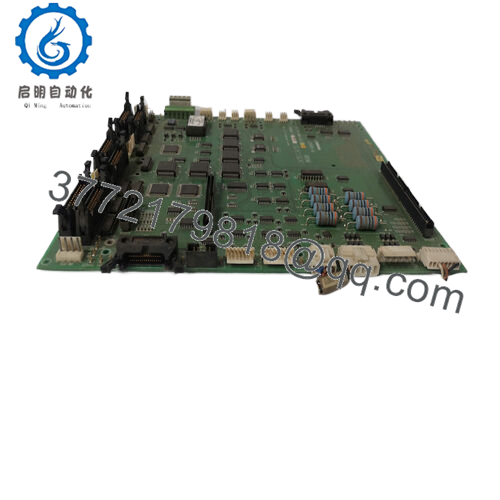

Description

Where is this product used and why?

The TOSHIBA ARND-3119 A6 2N3A3119-B is widely used in demanding industrial automation applications where precision control, reliability, and enhanced safety are essential. It is prominently applied in heavy industries such as power generation, petrochemical, and general manufacturing automation. Designed to meet rigorous operational demands, this module manages complex control signals within programmable logic controller (PLC) systems, facilitating robust machinery control and monitoring. The ARND-3119 A6 2N3A3119-B supports safety-critical functions, making it highly suitable for environments where system integrity and personnel safety are paramount. Its integration capabilities enable efficient management of motor control and other power system elements, helping engineers address challenges such as process stability, fault diagnostics, and scalable automation. By delivering high-performance outputs and real-time monitoring, this Toshiba automation module is instrumental in minimizing downtime while optimizing industrial production workflows.

Product introduction & positioning

The TOSHIBA ARND-3119 A6 2N3A3119-B is a high-performance control module designed for industrial automation applications, particularly within PLC systems. It serves as a critical interface for motor control and automation solutions, supporting both real-time data processing and safety functions such as Safe Torque Off (STO) and Safe Stop 1 (SS1). Recognized for its compliance with Safety Integrity Level 3 (SIL 3) and Performance Level e (PLe), this module provides dual-channel monitoring and real-time diagnostics to enhance system safety and reliability. The 2N3A3119-B fits into Toshiba’s automation and control ecosystem, seamlessly cooperating with complementary modules and networked devices to build scalable, safe, and precise control architectures. Its role is pivotal in controlling variable-speed drives, power distribution, and other critical control tasks, making it an indispensable tool for engineers integrating modern safety standards with powerful automation features.

Key technical features & functional benefits

The TOSHIBA ARND-3119 A6 2N3A3119-B boasts advanced input/output capacity tailored for complex industrial control environments. Its safety certifications SIL 3 and PLe demonstrate a high reliability benchmark suitable for applications with stringent safety requirements. Key features include Safe Torque Off (STO) and Safe Stop 1 (SS1) functionality, ensuring swift and reliable motor shutdowns during emergency or fault conditions. The module’s dual-channel monitoring architecture detects discrepancies between safety channels, significantly lowering the risk of undetected faults.

- 2N3A3620-B

Durability and operational stability are cornerstones of this module’s design. It delivers fast response times with accurate signal processing, essential for managing motion and process control tasks where timing precision is critical. Integrated real-time diagnostics provide continuous health checks, allowing predictive maintenance before failures occur. Its robust electronics and connectors are built to withstand harsh industrial temperatures and environments.

Furthermore, the ARND-3119 A6 supports flexible integration within Toshiba’s broader automation lineup, enhancing overall system responsiveness and fault tolerance. Compatibility with other TMEIC automation devices allows the creation of comprehensive, modular control solutions optimized for high efficiency and safety.

Detailed technical specifications

| Parameter | Value |

|---|---|

| Model | ARND-3119 A6 2N3A3119-B |

| Brand | Toshiba (TMEIC) |

| Product Type | Industrial Automation Control Module |

| Safety Certification | SIL 3, Performance Level e (PLe) |

| Safety Functions | Safe Torque Off (STO), Safe Stop 1 (SS1), Dual-channel monitoring |

| Input/Output Capacity | High capacity suitable for motor and power system control |

| Real-time Diagnostics | Yes, continuous health monitoring |

| Response Time | Fast, suitable for real-time motion and process control |

| Operating Temperature Range | Industrial grade; specifics depend on installation |

| Integration Compatibility | Compatible with Toshiba TMEIC automation ecosystem |

| Connectivity | Supports advanced field communication and network protocols |

| Durability | Designed for harsh industrial environments |

Related modules or compatible units

TMEIC MICOMP127 – Complementary control processor module enabling complex automation functions.

TMEIC 3700A – Variable frequency drive for motor speed control, functions well with ARND-3119 A6.

TMEIC DI3301S2 – Digital input module enhancing system input capacity and flexibility.

TMEIC VM600IOCN200-566-000-113 – Communication interface module for network integration.

TMEIC SST-PB3-CLX-RLL – Safety relay module providing extra safety layers in automation systems.

TMEIC VM600MPC4200 – High-performance motion controller integrated with ARND-3119 A6 capabilities.

TMEIC HV5000 – High voltage drive compatible with Toshiba automation modules for heavy industrial use.

Installation notes & maintenance best practices

Installing the TOSHIBA ARND-3119 A6 2N3A3119-B requires mounting within compatible rack or panel environments, ensuring solid mechanical connections and appropriate ventilation to maintain ambient temperatures. Proper grounding and shielding against electrical noise are essential to maintain signal integrity and module longevity. Ensure that the module firmware is up-to-date and verify compatibility with existing system controllers before integration. Personnel should handle the module with electrostatic discharge (ESD) precautions during installation or maintenance.

Maintenance should involve regular inspections of functional status via built-in diagnostics and fault indicators. Scheduled firmware checks and updates help maintain compliance with evolving safety standards and performance improvements. Employ predictive maintenance by analyzing diagnostic alerts to preemptively resolve issues before failure. Periodic cleaning of connectors and environment checks within control panels to avoid dust and moisture accumulation also contribute to optimal module performance.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626