Description

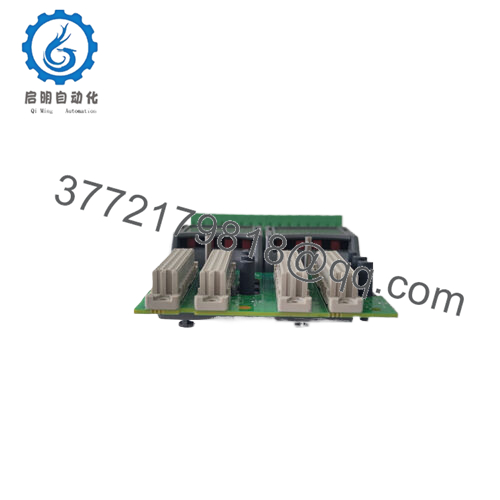

T9802 is a digital output module designed to become an indispensable part of industrial control systems. It is usually associated with respected manufacturers in the field of industrial automation, such as those in the ICS Triplex product line. This module serves as a bridge between the central control system and field level actuators, converting control commands issued by the system into electrical signals that can be executed by the actuators.

T9802

In industrial control architecture, T9802 is placed in the output subsystem. It receives digital signals from the central processing unit (CPU) of the control system. These signals carry information about the expected state of the industrial process, such as the position of the robotic arm or the speed of the conveyor belt. Then, T9802 processes these signals and sends corresponding electrical outputs to drive actuators, which may include motors, solenoid valves, and relays.

For engineers and system integrators, T9802 has significant value. Its design facilitates integration into existing control systems, whether based on programmable logic controllers (PLCs) or more complex distributed control systems (DCS). It provides flexibility in the number of output channels and the types of loads that can be driven, making it suitable for various industrial applications.

T9802

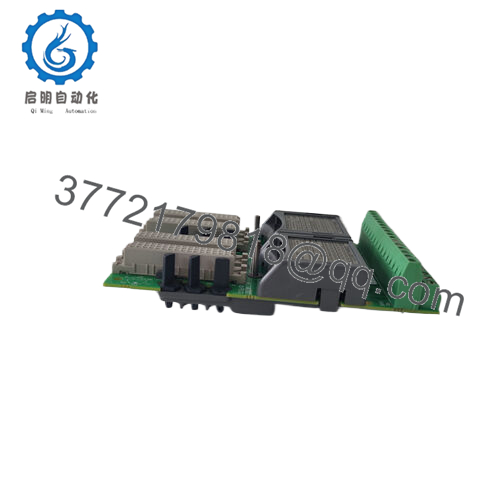

Main features and advantages:

T9802is typically equipped with a certain number of output channels, which may vary depending on the model. For example, some versions may have 8 digital output channels. This channel capacity enables it to control multiple actuators simultaneously, which is very advantageous in industrial environments that require coordination of numerous devices. In large manufacturing plants, there may be multiple conveyors, robotic arms, and other machinery that require separate control signals, andT9802 can efficiently handle these tasks.

Each output channel of T9802 is designed to handle specific currents, typically around 0.5A per channel. This current processing capability enables it to drive various loads, from small relays to large motors. In industrial applications, different actuators have different power requirements, and the ability of T9802 to provide appropriate current ensures the normal operation of the actuator. For example, it can power small solenoid valves that control liquid flow in chemical processing plants, or drive small motors that rotate parts processing mechanisms on manufacturing lines.

This module is also designed to operate within a specific voltage range. For example, its input voltage range may be 20-30V DC, with a working voltage of 24V DC. This voltage flexibility enables it to adapt to different power supply conditions in industrial environments. In some factories, due to electrical load fluctuations or the use of different power sources, the power supply voltage may vary slightly, but T9802 can still operate reliably within the specified voltage range.

In terms of environmental adaptability, T9802 is designed to withstand the harsh conditions commonly found in industrial environments. It can operate within a wide temperature range, typically from -20 ° C to 60 ° C. This temperature tolerance ensures that it can function properly in refrigeration facilities and high-temperature industrial processing areas. In addition, it is designed to resist vibration and electrical interference, which are common in industrial environments. This robustness helps maintain the integrity of the output signal and prevent any interference that may affect the operation of the actuator and ultimately impact the industrial process.

T9802

Technical specifications:

ModelT9802

Brand ICS Triplex

Type digital output module

Power input voltage range: 20-30V DC, operating voltage: 24V DC

Working temperature -20 ° C to 60 ° C

Storage temperature -40 ° C to 85 ° C

The installation method is designed to facilitate installation in the control cabinet, usually using standard installation mechanisms

Compact size, suitable for installation in control cabinets, approximately 100 x 80 x 30 millimeters

Lightweight, about 200 grams

The output channels are usually 8 digital output channels

Output type: numeric type

The current capacity of each channel is usually 0.5A per channel

Certification complies with industry standards such as CE, UL, CSA to ensure safety and quality

Environmental grade: resistant to vibration and electrical interference, suitable for industrial environments

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

T9802

Application areas:

In the manufacturing industry, especially in the field of electronic manufacturing that requires extremely high precision, T9802 plays a significant role as a digital output module. For example, in the production process of printed circuit boards (PCBs), robotic surface mount machines rely on T9802 to control the movement of their precision fixtures. These machines require tiny electronic components such as microchips and resistors to be placed on PCBs with sub millimeter precision.T9802 sends precise digital signals to the motor and actuator of the SMT machine to ensure that each component is placed in the correct position. This not only improves the quality of the PCB, but also significantly enhances production efficiency, as any placement error can result in expensive rework or even the entire circuit board being scrapped.

In the power generation industry, T9802 plays a crucial role in ensuring the stable operation of power plants. In coal-fired power plants, it controls the opening and closing of valves that regulate the flow of steam to the turbines. By accurately sending digital output signals, T9802 can adjust steam flow according to power demand. During peak electricity consumption periods, it will increase the valve opening to allow more steam to enter the turbine, thereby increasing power generation. On the contrary, during periods of low electricity consumption, it reduces steam flow to save fuel and maintain optimal operating conditions for the power plant. Given the high risk of power generation, any interruption could lead to widespread power outages, making the reliability and accuracy of T9802 crucial.

T9802

Related products:

T9801- Digital Input Module. Although T9802 focuses on sending control signals to actuators, T9801 is responsible for receiving digital signals from sensors. They together form the input-output loop in the control system, enabling the control system to monitor industrial processes through sensors connected to T9801, and then take action on information through actuators connected to T9802.

AADvance CPU module XYZ – the central processing unit of the control system, communicates with T9802. It sends control commands to T9802 based on the data received from the input module (such as T9801) and the executed control algorithm. Then, T9802 drives the actuator based on these commands.

Analog output module ABC – This module is used to control devices that require analog signals, such as variable frequency drives. In contrast, T9802 processes digital outputs. However, in some complex industrial control systems, digital and analog output modules may be used together to control various actuators.

Communication module DEF – facilitates communication between T9802 and other components in the control system with external devices or other control systems. It supports data transmission through different protocols such as Ethernet or Modbus, enabling system integration and remote monitoring. This is very useful for scenarios that require monitoring or controlling industrial processes from a central control room, or integrating with other systems in large industrial complexes.

Power module GHI – ensures stable and reliable power supply for T9802 and other modules in the control system. Appropriate power supply is crucial for the accurate operation of T9802, as any power fluctuations can lead to incorrect output signals and interfere with industrial processes.

Terminal block module JKL – used to connect actuators and other field devices to T9802. It provides a convenient and orderly electrical connection method, ensuring reliable signal transmission between modules and actuators.

Installation and maintenance:

Before installing T9802, it is necessary to carefully plan the installation location. Ensure that the control cabinet has sufficient space to accommodate the module and consider its size. Appropriate ventilation should be provided inside the cabinet to dissipate the heat generated during module operation. Check the power supply voltage and ensure it is within the specified range of 20-30V DC. When connecting actuators and control systems, appropriate wiring techniques should be used to prevent electrical interference. Ensure that all connections are secure to avoid intermittent or complete loss of output signals caused by loose connections.

For maintenance, it is recommended to conduct regular visual inspections. Check at least once a month for any signs of physical damage, such as cracked casing or loose connectors. Regularly (every three months) conduct functional testing to ensure that all output channels are functioning properly. This can be accomplished by sending known control signals to T9802 and verifying whether the actuator responds as expected. Pay attention to the operating temperature of the module, as overheating may cause component failure. If the module is installed in a dusty environment, it should be cleaned regularly with compressed air to prevent dust accumulation from affecting its performance. Stay up-to-date with the latest firmware versions released by manufacturers, as these versions may include bug fixes, performance improvements, and enhanced features.

Other product models of ICS brand:

ICS T8310

ICS TRIPLEX T9100

ICS T8231

ICS T8461

ICS TRIPLEX T8403C

ICS T8472C

ICS TRIPLEX T8110B

ICS TRIPLEX T8461

ICS TRIPLEX T8480

ICS TRIPLEX T8442

ICS T8111C

ICS TRIPLEX T8110C

ICS T8231 with power fan

ICS TRIPLEX T8310

ICS TRIPLEX T8191

ICS TRIPLEX T8431

ICS TRIPLEX T9482

ICS TRIPLEX T9110

ICS TRIPLEX T8310

ICS TRIPLEX T8431

ICS TRIPLEX T8403

ICS TRIPLEX T8461

ICS Triplex T8231C

ICS T8111C

ICS T3481A

ICS T8151C

ICS T8403C

ICS T8431

ICS T8431C

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626