Description

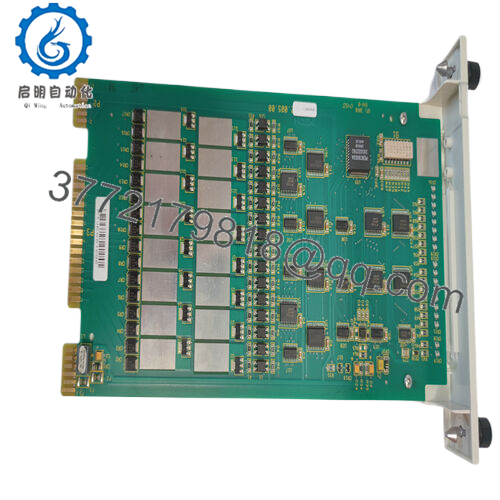

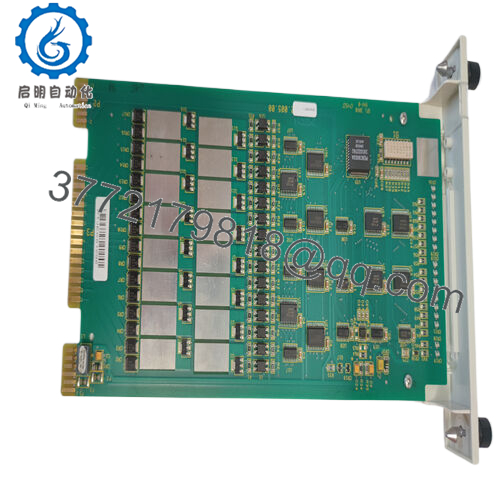

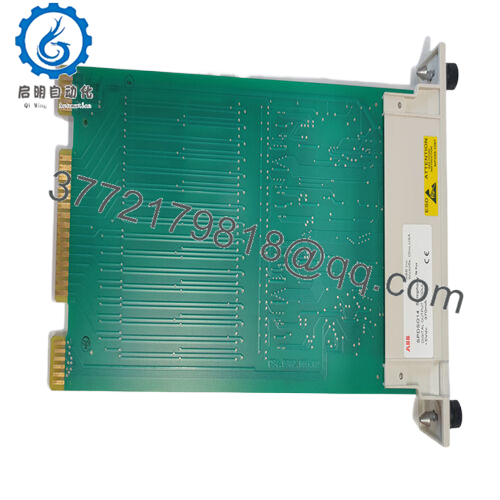

Product Model: SPDSO14

Product Brand: ABB

Product Series: Symphony Plus / Infi90 I/O – Digital Output Slave

Product Features:

- 16 independent digital output channels (open-collector) designed for field device control.

- Operates at 24 VDC (and in many cases supports 48 VDC loads) with robust switching capability.

- Designed for use in automation systems (process, manufacturing, utilities) where reliable output signalling is essential.

- Compact rack-mount or module form factor, plug-in into the Harmony/Symphony I/O architecture for rapid replacement and minimal downtime.

- SPDSO14

- SPDSO14

Product Role & System Fit

In many industrial control systems, especially those based on the ABB Symphony Plus or legacy Infi 90 platforms, the interface between the controller’s logic layer and the field actuators is critical. The SPDSO14 module serves this exact role: it is a digital output slave board that takes commands from the higher-level controller and translates them into output signals to drive external devices — such as valves, motors, solenoids, indicators, and relays.

The SPDSO14 fits into a modular I/O rack or mounting unit alongside input modules, power supplies, and bus communication modules. It is inserted into a module slot in the I/O mounting unit, connects via the backplane I/O bus (expander bus) to the controller, and interfaces to the field via its output channels. In essence, when your control program says “open valve X” or “start motor Y”, the SPDSO14 is what toggles the actual hardware.

For system integrators or maintenance engineers, the SPDSO14 is frequently stocked as a spare due to its central role in output signalling. If output channels begin to fail — for instance some actuators stop responding — replacing the SPDSO14 often restores full function without redesigning the I/O topology. Because of its plug-in form factor and compatibility with the Harmony/Symphony architecture, you can drop it in and resume operation rapidly.

Given that the module supports 16 open-collector outputs, it’s also well suited for distributed control system (DCS) applications where multiple loads must be actuated individually. Whether in water/wastewater treatment, chemical processing, power generation, or manufacturing lines, SPDSO14 brings the reliability and modularity engineers require.

Applications & Industry Context

Consider a water treatment plant where multiple pumps, solenoid-actuated valves and chemical dosing lines must be operated in sequence. The control system may run on ABB’s Symphony Plus platform, and the SPDSO14 provides the digital outputs that drive each actuator. When maintenance staff report “some valves are not energising”, the SPDSO14 is one of the first modules to inspect or replace.

In a power generation facility, where feed-water valves, generator exciters, and control fan actuators are controlled digitally, having a robust output module is essential to maintaining uptime. The SPDSO14, with its “digital output slave” role, fits in such environments where reliability, redundancy and fast replacement are important.

In manufacturing or process automation — say in pulp & paper, or cement plants — the environment may be harsh (dusty, humid, subject to temperature swings). Modules like the SPDSO14, originally designed for ABB’s process automation I/O family, bring the ruggedness needed. Engineers often mention that when an SPDSO14 has intermittent output failures or LED indications of malfunction, replacing it restores control without needing to rebuild the application.

From retrofit projects through to new installations, the SPDSO14 continues to be relevant because it supports the standard I/O architecture of ABB’s control ecosystem. For older installations still running the Infi 90 or SP (Symphony) controllers, the SPDSO14 is backwards compatible and helps extend system life.

Technical Features & Benefits

The SPDSO14 stands out thanks to several technical design features and related benefits:

16-Channel Open Collector Outputs

This module supports 16 discrete outputs, each of which operates in open-collector mode (sinking current) making it suitable for a wide range of field device types.

Benefit: You can drive multiple actuators directly from a single module, reducing the number of modules required in your rack and simplifying inventory.

24 VDC / 48 VDC Load Compatibility

While many installations use 24 VDC for field loads, the SPDSO14 supports flexibility (24V or 48V depending on variant) enabling broader deployment across global sites.

Benefit: Makes the module adaptable to existing field wiring and standard load voltages, reducing change-out cost.

Rapid Response & Diagnostics

According to ABB documentation, the module boasts high-speed response and status LED indicators for each output channel, plus module-level diagnostics (e.g., front panel module status LEDs and output state LEDs) which simplify maintenance.

Benefit: Faster troubleshooting, less downtime. You can visually inspect LED indicators to see exactly which outputs are active or failed.

Plug-in Modular Design

The SPDSO14 is designed for insertion into a module mounting unit (MMU) with backplane connections for power and communication bus, meaning installation or replacement is relatively straightforward.

Benefit: Reduced downtime during maintenance and easier system upgrades or component replacements.

Robust Industrial Environment Rating

Built with industrial-grade components, the module is suitable for process industry environments where dust, temperature variation, and noise are present. The ABB manual notes ambient temperature range, proper I/O bus isolation and recommended maintenance.

Benefit: Increased lifetime and lower risk of failures under harsh conditions.

In summary, employing the SPDSO14 module in a control system offers a blend of high channel density, flexible voltage handling, diagnostics, and ease of replacement — all of which matter when your process cannot tolerate downtime.

Technical Specifications Table

| Specification | Detail / Value |

|---|---|

| Product Model | SPDSO14 |

| Manufacturer | ABB |

| Module Type | Digital Output Slave Module |

| Number of Output Channels | 16 |

| Output Type | Open Collector |

| Load Voltage | 24 VDC (with variants up to 48 VDC) |

| Typical Response Time | < 1 ms based on module documentation |

| Mounting / Form Factor | Plug-in into module mounting unit backplane |

| Weight | ~0.2 kg typical |

| Environmental Range | –25 °C to +55 °C typical for process environments |

| Family Compatibility | ABB Symphony Plus / Infi 90 control systems |

| Diagnostics | Status LEDs for module & each output channel |

| Documentation | User Manual 2VAA001623 |

Related Models

Here are modules you might consider alongside or as alternatives to the SPDSO14:

- SPDSI14 – Digital Input Module (16-channel input) for the same I/O family.

- IMDSO14 – Equivalent module under the older Infi 90 branding (SPDSO14 is the re-branded version)

- SPDSO22 – A higher-channel or alternative digital output module variant (check your I/O mapping)

- SPDSO12 – Smaller or older version with fewer channels (if channel count is less critical)

- SPCSIO14 – Mixed I/O or other slave modules in the same Symphony I/O family

Installation & Maintenance Insights

Although the SPDSO14 is designed for straightforward deployment, real-world experience shows that careful attention to installation and maintenance makes a difference in longevity and reliability:

- Check Bus Connections and Backplane Contacts: Before inserting the module, verify that the module mounting unit (MMU) backplane contacts are clean, free of corrosion, and properly seated. A misalignment often causes intermittent failures. The user manual explains how the module connects via P1, P2 and bus expansion connections.

- Power Down Before Insertion/Removal: To avoid bus faults or damage to the module, ensure that logic power is turned off before swapping modules. The front-panel status LEDs can signal bus-fault conditions if modules are replaced under live conditions.

- Verify Field Wiring: Since each of the 16 outputs is an open-collector sink, ensure field wiring is compatible (i.e., load supply and sink arrangement) and that loads don’t exceed the module’s specified current rating (as per site documentation). Overloaded channels shorten module life.

- Use Spare Modules Strategically: Given that this module is a common failure point (due to field wiring, surge events, or output channel stress), keeping a spare SPDSO14 in stock can facilitate rapid swap-out and restore of process operation.

- Monitor Output Channel LEDs: The panel of 16 output LEDs provides immediate visual indication of channel status. Use this during commissioning and routine checks to detect stuck outputs or wiring faults.

- Periodic Maintenance: Every six months (or per plant practice), inspect the MMU for dust, moisture or corrosion. If the environment is harsh (high humidity, condensation, chemical mist), consider protective measures or using modules in a lower risk area.

- Firmware/Configuration Check: Although the SPDSO14 is primarily hardware, ensure that the controller configuration (e.g., I/O addressing, function codes) reflects the correct slot address for the module. A mis-addressed module often appears as “missing I/O slave” on the controller.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626