Description

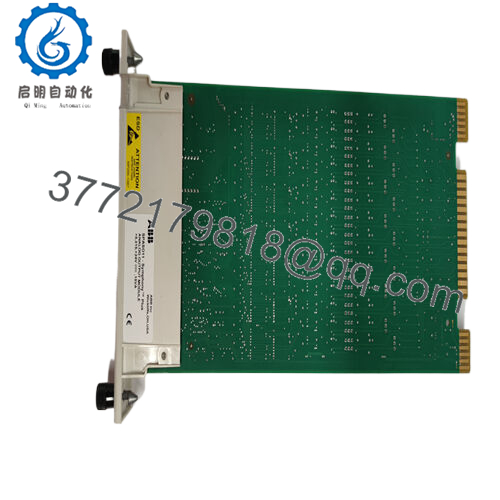

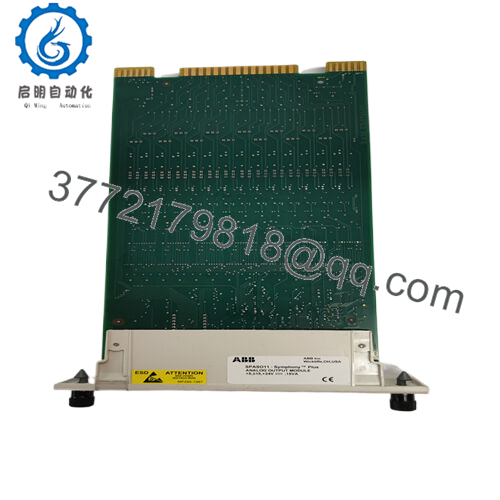

Product Model: SPASO11

Product Brand: ABB

Product Series: Symphony Plus / Infi 90 I/O (Analog Output Slave)

Product Features:

- 14 independent analog output channels supporting 4-20 mA and 1-5 V signals

- Slave (I/O) module that interfaces with DCS / control bus and drives field analog loads

- Compact plug-in module form, suitable for modular I/O racks in industrial process environments

- High precision output, support for multiple output signal ranges (4-20 mA, 1-5 V)

Product Role & System Context

In a modern process automation architecture, bridging the gap between controller logic and real physical devices is crucial. The SPASO11 module plays exactly that bridging role: it translates digital commands from the control system into analog signals that actuators, valves, or other analog devices can act upon.

In ABB’s Symphony Plus and legacy Infi 90 systems, field devices often expect analog signals—4-20 mA loops or voltage signals such as 1-5 V. The SPASO11 is a slave I/O module dedicated to that analog output domain. When your controller logic says “open valve to 50 %”, SPASO11 will output the proportional analog current (or voltage) to the valve actuator or control device.

From a system integrator’s perspective, this module is not a standalone controller but part of the distributed I/O architecture. It resides in an I/O rack or mounting unit, connected via a backplane or bus to the controller (master). It gets commanded via bus protocol, then maps outputs to the physical terminals. If you have multiple analog loads (e.g. modulating valves, proportional control devices), the SPASO11 is one of the essential building blocks.

Because of its analog output role, when SPASO11 fails or drifts, control loops degrade—valves don’t modulate correctly, actuators receive improper signals, and control stability suffers. Many engineers keep SPASO11 modules in spare inventory for fast swap-outs, precisely because downtime in analog control is costly.

In systems that evolved from older DCS / Infi 90 architectures to modern Symphony Plus, the SPASO11 typically retains backward compatibility, enabling reuse of field wiring and reducing upgrade cost. In many installations, SPASO11 is the renamed successor to older “ASO11” or “IMASO11” analog output modules.

Thus, the SPASO11 fits into the control system as the analog output interface—the last mile of signal conversion before the real world.

Applications & Real-World Use

Analog output modules are widely used in process industries: chemical plants, power generation, oil & gas, water/wastewater, pulp & paper, pharmaceuticals and more. Wherever you need fine modulation—not just “on/off” but variable control—the SPASO11 shines.

For instance, in a chemical reactor, the feed valve or flow control valve may require a 4-20 mA input. The controller’s output signal is sent to the SPASO11, which then drives the actual valve actuator. If SPASO11 is out of calibration, the valve may never reach the commanded position, leading to process instability.

In a power plant’s boiler feed system, the speed of feed pumps or damper actuators may be controlled via analog outputs. Each such control loop can depend on a reliable SPASO11 channel. If one channel fails, that loop may go open or saturate, causing control alarms or fallback modes.

In retrofit or expansion scenarios for legacy Infi 90 systems, SPASO11 is often adopted as a drop-in replacement of IMASO11. Many field service houses refer to SPASO11 under its legacy naming, enabling smoother upgrades.

In environments with harsh conditions (temperature swings, vibration, humidity), having a well-designed analog output module reduces drift, noise injection, and failure. Operators report that replacing a drifting SPASO11 often restores stable control performance without needing to re-tune the control loops from scratch.

Because it supports 14 channels per module, SPASO11 allows for high density, reducing I/O rack count and wiring complexity—particularly helpful in large plants with many analog control loops.

Technical Features & Benefits

Let’s dig into what makes SPASO11 attractive in real plants:

14 Analog Output Channels, Mixed Signal Types

The SPASO11 supports 14 discrete analog outputs, often configurable for 4-20 mA or 1-5 V signal ranges.

Benefit: High channel density makes it economical in I/O rack space and wiring complexity.

Support for Both Current and Voltage Output Modes

Many installations still use voltage outputs (1-5 V), while process control standards often use current loops (4-20 mA). SPASO11 caters to both modes.

Benefit: Flexibility to adapt to legacy wiring or newer standard loops without needing multiple module variants.

Precision & Signal Integrity

Analog modules like SPASO11 are designed for low drift, good linearity, stable offsets, and robustness against noise or electromagnetic interference. Supplier listings highlight high precision performance.

Benefit: Better control accuracy, fewer tuning corrections, and more stable loops over time.

Modular Plug-in Form Factor

The module is designed to be plug-in within the I/O rack, with backplane connectivity. This simplifies replacement and field maintenance.

Benefit: Fast field swaps, reduced downtime, minimal rewiring.

Diagnostic Visibility

Though not always exposed in every vendor listing, analog I/O modules often include status LEDs, internal diagnostics (such as open circuit detection), and bus communication status. These help identify a failing channel or module. (This is typical in ABB’s I/O module philosophy.)

Benefit: Faster troubleshooting and less blind guessing in complex systems.

Legacy Compatibility & Interoperability

SPASO11 is part of the Symphony Plus (and back-compatible with Infi 90 / Bailey) I/O platform. It may replace or emulate older analog module models like IMASO11.

Benefit: Lower upgrade cost, reuse of existing field wiring, smoother migration path.

Industrial-Grade Construction

While specific ruggedness specifications may need checking, modules in ABB’s I/O family are typically rated for industrial ambient conditions, vibration tolerance, and EMI immunity.

Benefit: Longer lifetime and lower failure rate in harsh plant environments.

In field experience, replacing an aging SPASO11 with a fresh unit often resolves symptoms like actuator drift, stable offsets, or analog loop errors—without needing to retune entire loops. That makes SPASO11 not just a module, but a key contributor to system reliability.

Technical Specifications Table

| Specification | Detail / Value |

|---|---|

| Module Model | SPASO11 |

| Module Type | Analog Output Slave Module |

| Number of Output Channels | 14 |

| Supported Output Signals | 4-20 mA, 1-5 V (depending on configuration) |

| Platform / Compatibility | ABB Symphony Plus, Infi 90 / Bailey I/O family |

| Legacy Equivalent | IMASO11 (older naming) |

| Weight / Physical Size | Moderate size (module dimensions as per vendor) |

| Typical Operating Environment | Industrial ambient conditions (vibration, temp) |

| Diagnostic Features | Status LEDs / internal channel diagnostics (typical) |

| Mounting / Connectivity | Plug-in into I/O rack / backplane |

| Warranty (typical) | 12 months when purchased new from authorized sellers |

Related Modules & Alternatives

Here are modules and variants commonly used alongside or in place of SPASO11:

- SPDSI14 – The digital input counterpart module in the same I/O family.

- IMASO11 – The legacy analog output module name often replaced by SPASO11 in Infi 90 / Bailey systems.

- SPASO12 / SPASO22 – Potential variants with different channel counts or scaling (depending on system).

- Analog Input Modules (SPASIxx / IMASIxx) – For reading signals from sensors, used alongside SPASO11 in control loops.

- Digital Output / Input Modules (e.g. SPDSOxx, SPDSIxx) – For switching or discrete I/O operations in the same I/O rack.

- Analog Redundant / High-Integrity Output Modules – In critical systems, redundant analog output modules might be used for fail-safe operation.

- SPASO11

- SPASO11

Installation & Maintenance Insights

From hands-on experience and best practices in the field, here are tips for making the most of SPASO11 in real plants:

- Ensure Bus & Rack Integrity

Before inserting SPASO11, verify that the I/O rack backplane and bus connectors are clean, undamaged, and properly aligned. Faulty bus contacts are a common cause of communication glitches. - Power Down Before Swapping

Always de-energize the analog bus or logic power before inserting or removing SPASO11. Hot-swapping can lead to bus errors or damage. - Wiring Verification

Because outputs can be either current loop or voltage mode, double-check wiring and terminal settings. Mistaken wiring (open circuits, reversed polarity) can lead to errors or locked loops. - Check Field Load Compatibility

Ensure actuators, valves, or downstream devices match the output mode (e.g., whether 4-20 mA sink or source, or 1-5 V). Overloading a channel shortens module life. - Use Spare Modules Strategically

Keep at least one spare SPASO11 on hand. In many control rooms, a faulty analog channel may be traced to drift or failed electronics; having a ready module enables quick swap and restores performance. - LED & Diagnostic Check

After inserting SPASO11, allow the module to go through its self-tests. Observe status LEDs to confirm proper startup and healthy channel states. - Calibration & Verification

After installation, verify outputs using calibrated instruments. Confirm that 4 mA maps to the correct field value and 20 mA to full scale. Minor trimming may be required. - Periodic Maintenance

During scheduled outages, inspect the I/O rack for dust, corrosion, and temperature stress. Gently blow out dust and ensure signal connections remain tight. - Document Module Version & Serial

Record module part number, firmware or revision (if available), and installation date. That helps later in traceability, troubleshooting, or warranty claims. - Monitor Analog Loop Trends

Keep logs of actual current output vs commanded digital values. If small offsets or drift start creeping in over months, it’s often early warning of module aging.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626