Description

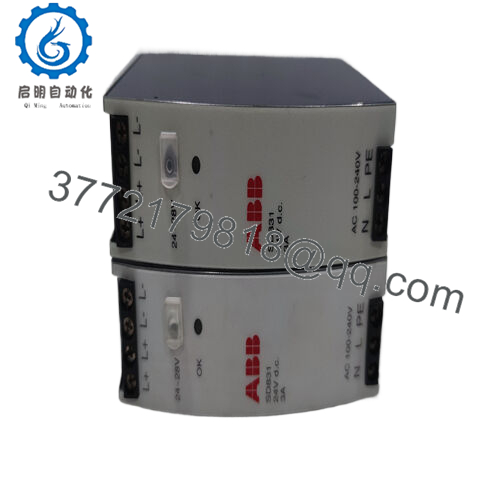

| Model Number | SD831 |

| Brand | ABB |

| Type | High-Power Servo Drive |

| Input Voltage | 380-480V AC (three-phase) |

| Output Current | 31A continuous, 62A peak |

| Operating Temp Range | -10°C to +55°C (ambient) |

| Mounting Style | Panel Mount with heatsink |

| Dimensions | 220mm x 180mm x 150mm |

| Weight | 3.2kg |

| Interface/Bus | EtherCAT, PROFINET, Modbus TCP |

| Compliance | CE, RoHS, UL 61800-5-1 |

| Supported Protocols | CANopen, EtherNet/IP |

| Typical Power Draw | 18kW max output |

SD831

The SD831 addresses these needs by serving as a high-power servo drive engineered for heavy-duty industrial applications. In real-world scenarios—from large-scale material handling systems to precision metalworking machinery—where both high torque and accurate positioning are essential, the SD831 becomes indispensable. It ensures that motors deliver consistent performance even under extreme load conditions, responding precisely to control signals and maintaining stability across dynamic operations, forming a vital link in maintaining process efficiency and system reliability. By overcoming the limitations of lower-capacity drives, the SD831 plays a key role in enabling high-performance industrial automation workflows.

SD831

Functionally, the SD831 operates as a rugged, high-current servo drive that connects advanced control systems with heavy-duty motors, positioning itself as a cornerstone in the motion control layer of large-scale automation stacks. It interfaces seamlessly with PLCs, motion controllers, and HMI systems via cutting-edge industrial communication protocols, translating complex control signals into precise motor movements while providing real-time feedback on critical parameters like torque, speed, and position. This bidirectional communication enables sophisticated closed-loop control, ensuring that motors maintain exact operational parameters regardless of load variations or external disturbances.

SD831

Main features and advantages:

The SD831 supports a wide range of high-power servo motors, making it versatile for applications from large conveyors to precision machine tools. A key feature of the SD831 is its advanced adaptive control algorithms, which automatically optimize performance based on changing load conditions and motion profiles. Additionally, the drive’s robust design includes comprehensive protection mechanisms—such as short-circuit, overvoltage, undervoltage, and thermal overload protection—ensuring reliable operation even in the most demanding industrial environments. Its modular architecture simplifies integration into existing systems, allowing for straightforward installation, expansion, and upgrades as operational needs grow.

Choosing the SD831 delivers substantial operational benefits that enhance both machinery performance and overall productivity in heavy-duty applications. Engineered for industrial ruggedness, the drive is built to withstand harsh factory environments, including electrical noise, voltage transients, and mechanical vibration, ensuring long-term reliability and minimizing the risk of unplanned downtime. Its high-power capacity eliminates the need for multiple lower-capacity drives in parallel, simplifying system architecture, reducing wiring complexity, and lowering overall engineering overhead.

The advanced diagnostics suite of the SD831 provides maintenance teams with deep insights into motor performance and drive health, enabling proactive identification of potential issues before they impact production. This predictive capability not only reduces maintenance costs but also extends equipment lifespan by preventing premature wear caused by suboptimal operation. The drive’s intuitive configuration software simplifies setup and tuning, allowing engineers to optimize complex motion profiles quickly and adapt to changing production requirements with minimal downtime. By ensuring precise, consistent motor operation even under heavy loads, the SD831 helps improve process accuracy, reduce material waste, and enhance overall product quality.

SD831

Application areas:

The SD831 is deployed across a range of heavy-industry sectors where high-power motion control is critical to operational success. In automotive manufacturing, it plays a key role in controlling robotic welding arms and large material handling systems, delivering the high torque needed for heavy part manipulation while maintaining the precision required for assembly accuracy. Its ability to handle high continuous loads makes it ideal for use in metal processing machinery, where it controls rolling mills, stamping presses, and CNC machine tools—applications where consistent torque and speed are essential for product quality.

In logistics and material handling, the SD831 excels at powering large conveyor systems and automated storage retrieval machines, providing the reliability needed for 24/7 operation in distribution centers. The drive’s rapid response time is particularly valuable in high-speed packaging lines handling heavy products, where precise synchronization between multiple axes ensures efficient throughput. Across all these applications, the SD831 supports critical system uptime by delivering reliable, high-performance motion control, making it an invaluable asset in process control environments where power, precision, and durability are paramount.

SD831

Related products:

SD820 – Mid-range variant (20A continuous) for medium-power applications.

SD840 – Higher capacity model (40A continuous) for extreme heavy-duty applications.

SD831-L – Low-voltage version (200-240V AC) for regions with different power infrastructure.

SD831-S – Safety-enhanced model with STO, SS1, and SS2 functions for safety-critical systems.

SD831-M – Multi-axis controller variant for coordinating synchronized motion systems.

SD831-E – EtherCAT master version optimized for high-speed multi-axis coordination.

SD831-P – Compact version with integrated brake chopper for space-constrained installations.

SD831

Installation and maintenance:

Before installing the SD831, verify compatibility with your servo motor’s specifications, including voltage rating, current requirements, and feedback device compatibility (absolute encoder, resolver). Ensure the installation location provides adequate cooling, as the drive generates significant heat during operation—maintain a minimum of 100mm clearance around the unit and confirm ambient temperature stays within the operating range. Check that the three-phase power supply is properly configured, filtered, and protected with appropriate circuit breakers and fuses sized according to the drive’s specifications.

For ongoing maintenance of the SD831, regularly inspect the status indicators during routine checks—LED displays provide real-time status updates, while fault codes offer specific diagnostic information (refer to the user manual for detailed troubleshooting guidance). Quarterly inspections of all power and signal connections are recommended to check for tightness, corrosion, or overheating signs, which can cause voltage drops or communication issues. Perform firmware updates semi-annually through the manufacturer’s configuration software to access the latest performance enhancements and safety features. Clean cooling fans and heatsinks monthly to prevent dust buildup, which can impede heat dissipation and lead to thermal shutdowns.

Other ABB product models:

ABB 3BHE044249R0003

ABB 3BHE046836R0101

ABB 3BHE046836R0102 GFD563A102

ABB 3BHL000250P0002

ABB 3BHL000391P0101 5SHX1445H0001

ABB 3BHL000406P0009

ABB 3BHL000406P0103

ABB 3BHL000519P0001

ABB 3BHL000734P0003

ABB 3BHL000986P0006

ABB 3BHL001433P0001

ABB 3BHT300011R1

ABB 3BSE003816R1 SC520

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004172R1 PFTL101A-2KN

ABB 3BSE004172R1 PFTL101A 2KN

ABB 3BSE018135R1

ABB 3BSE019050R200 PFTL301E-0.2kN

ABB 3BSE030928R1 SM810K01

ABB 3BSE042235R2

ABB 3BSE042236R1 PP865

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE043660R1 CI867K01

ABB 3BSE056899R1 CI873K01

ABB 3BSE066490R1

ABB 3BSE076939R1 PM866AK01

ABB 3BSE091722R1 LD 810HSE EX

ABB 3BSE092689R1

ABB 3BSE092689R1 CI867AK01

ABB 3BSE092978R1 PP881

ABB 3BUS208797-001

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626