Description

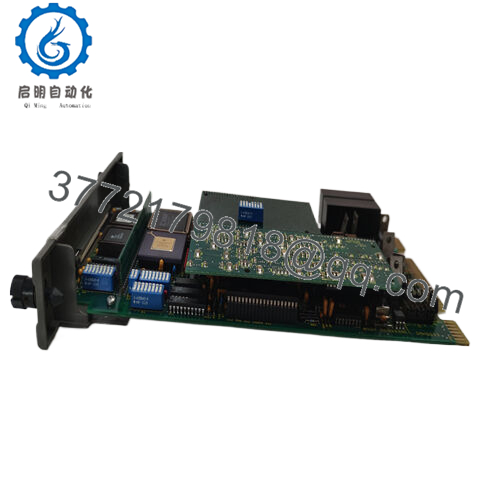

| Model Number | SCJIE00818 |

| Brand | ABB |

| Type | Digital Input Module |

| Input Voltage | 24V DC |

| Operating Temp Range | -30°C to +70°C |

| Mounting Style | DIN Rail |

| Dimensions | 110mm x 90mm x 65mm |

| Weight | 320g |

| Interface/Bus | Industrial Backplane Compatible |

| Compliance | CE, RoHS, UL 61010 |

| Supported Protocols | Modbus RTU, Profibus DP |

| Typical Power Draw | 2.1W |

SCJIE00818

The SCJIE00818 addresses these pain points by serving as a high-performance digital input module designed to streamline the integration of digital sensors and control devices into industrial control systems. In real-world scenarios—from automotive manufacturing lines to food processing plants—where rapid and accurate signal detection is essential, the SCJIE00818 becomes indispensable. It ensures that digital signals from proximity sensors, limit switches, and other devices are reliably transmitted to the central controller, forming a vital link in maintaining process control integrity and system stability. By overcoming common integration hurdles, the SCJIE00818 plays a key role in optimizing industrial automation workflows and supporting seamless operation.

SCJIE00818

Functionally, the SCJIE00818 operates as a dedicated digital input module that connects field devices to the broader automation system, positioning itself as a critical component in the I/O layer of the automation stack. It interfaces directly with standard industrial backplane systems, enabling smooth communication with PLCs and control systems while handling up to 16 digital input channels. This design allows engineers to consolidate multiple signal sources into a single, manageable module, reducing the complexity of wiring and system architecture.

SCJIE00818

Main features and advantages:

The SCJIE00818 supports common industrial protocols, ensuring compatibility with a wide range of control platforms, making it a versatile choice for both new installations and system upgrades.

A key feature of the SCJIE00818 is its built-in diagnostic capabilities, which provide real-time feedback on signal status and module health, allowing maintenance teams to quickly identify and resolve issues. Additionally, the module’s design includes surge protection and noise immunity, ensuring reliable operation even in environments with electrical interference or voltage fluctuations. Its modular construction simplifies integration into existing setups, allowing for easy installation and expansion as operational needs grow.

Application areas:

Choosing the SCJIE00818 delivers tangible benefits that enhance both system performance and operational efficiency. Engineered for industrial durability, the module is built to withstand the rigors of factory floors, including extreme temperature variations, vibration, and electromagnetic interference, ensuring long-term reliability and reducing the risk of unplanned downtime. Its high channel density—supporting 16 digital inputs—eliminates the need for multiple smaller modules, streamlining system design and reducing engineering overhead during installation and configuration.

The advanced diagnostics of the SCJIE00818 provide maintenance teams with actionable insights, enabling proactive identification of signal issues or potential module faults before they impact production. This predictive capability not only extends the lifespan of connected devices but also improves overall system availability. The module’s plug-and-play compatibility with common industrial protocols simplifies integration with existing control systems, reducing setup time and minimizing the need for specialized programming. By ensuring consistent and accurate signal transmission, the SCJIE00818 helps maintain process integrity, leading to improved product quality and operational efficiency.

Related products:

SCJIE00819 – Higher channel version with 32 digital inputs for larger-scale applications.

SCJIE00817 – Compact 8-channel digital input module for space-constrained installations.

SCJIE00820 – Digital output module for control signal generation, compatible with SCJIE00818.

SCJIE00825 – Mixed I/O module combining 8 digital inputs and 8 outputs for versatile setups.

SCJIE00830 – High-speed digital input module with advanced timestamping for precision applications.

SCJIE00840 – Redundant power supply module designed to pair with SCJIE00818 for critical systems.

SCJIE00850 – Communication gateway module enabling SCJIE00818 integration with Ethernet/IP networks.

Application areas:

The SCJIE00818 is deployed across a range of industrial sectors where reliable digital signal processing is critical to operations. In automotive manufacturing, it plays a key role in monitoring assembly line processes, receiving signals from part presence sensors and robotic position switches to ensure precise coordination of production steps. Its ability to operate in wide temperature ranges makes it ideal for use in metal processing facilities, where it tracks the position of conveyors and material handling equipment in environments with high heat and mechanical stress.

In food and beverage processing plants, the SCJIE00818 excels at monitoring hygiene-critical equipment, such as valve position sensors and cleaning cycle switches, ensuring compliance with strict safety standards. The module’s robust design ensures consistent performance even in washdown areas, where moisture and chemical exposure are common. Across all these applications, the SCJIE00818 supports critical system uptime by providing reliable digital input processing, making it a valuable asset in process control environments where precision and dependability are paramount.

Installation and maintenance:

Before installing the SCJIE00818, verify compatibility with your existing control system’s backplane and firmware version to ensure seamless communication. Check that the control cabinet provides adequate ventilation, as the module’s performance can be affected by prolonged exposure to temperatures beyond its operating range. Confirm that the 24V DC power supply is properly regulated and protected with appropriate fusing to prevent damage from voltage spikes or surges.

For ongoing maintenance of the SCJIE00818, regularly inspect the status LEDs during routine checks—steady green indicators confirm normal operation, while flashing or red lights signal potential issues requiring attention. Quarterly inspections of input connectors are recommended to check for corrosion or loose connections, which can cause signal degradation. Calibrate input thresholds annually using manufacturer-recommended tools to maintain detection accuracy. Keep module firmware updated through the control system’s software platform to access the latest performance enhancements and diagnostic features, ensuring the SCJIE00818 continues to operate at peak efficiency.

Other ABB product models:

ABB 3BHE044249R0003

ABB 3BHE046836R0101

ABB 3BHE046836R0102 GFD563A102

ABB 3BHL000250P0002

ABB 3BHL000391P0101 5SHX1445H0001

ABB 3BHL000406P0009

ABB 3BHL000406P0103

ABB 3BHL000519P0001

ABB 3BHL000734P0003

ABB 3BHL000986P0006

ABB 3BHL001433P0001

ABB 3BHT300011R1

ABB 3BSE003816R1 SC520

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004172R1 PFTL101A-2KN

ABB 3BSE004172R1 PFTL101A 2KN

ABB 3BSE018135R1

ABB 3BSE019050R200 PFTL301E-0.2kN

ABB 3BSE030928R1 SM810K01

ABB 3BSE042235R2

ABB 3BSE042236R1 PP865

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE043660R1 CI867K01

ABB 3BSE056899R1 CI873K01

ABB 3BSE066490R1

ABB 3BSE076939R1 PM866AK01

ABB 3BSE091722R1 LD 810HSE EX

ABB 3BSE092689R1

ABB 3BSE092689R1 CI867AK01

ABB 3BSE092978R1 PP881

ABB 3BUS208797-001

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626