Description

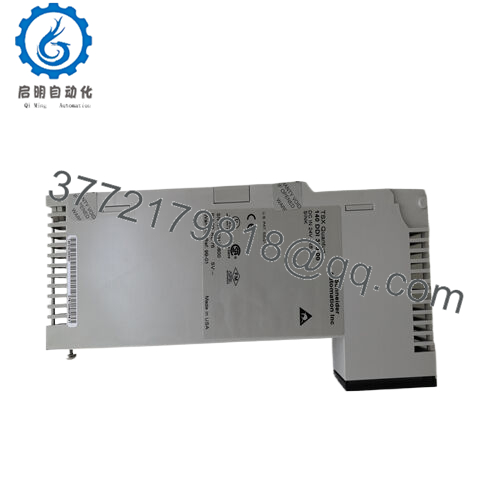

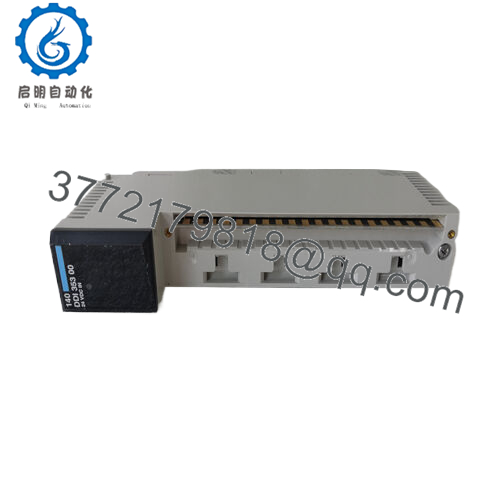

In the unforgiving arena of industrial automation, where field devices flood control systems with status updates from switches, proximity sensors, and limit detectors, engineers frequently clash with the chaos of unreliable discrete inputs—chatter from inductive spikes, group-wide failures from a single fuse blow, or insufficient channel density that forces sprawling cabinets and tangled wiring in process control backbones. Envision a high-volume bottling line: PLC logic must poll dozens of capper sensors and conveyor interlocks in real time, but a module prone to EMI-induced false triggers halts the chain, spilling product and spiking scrap by thousands per shift amid razor-thin margins. Or in a material handling yard, where forklift position detectors span dusty spans; without fused isolation per group, a shorted input cascades outages, stranding loads and eroding throughput in environments demanding unyielding high-reliability I/O signal capture. These disruptions peak in modular setups laced with variable frequency drives or solenoid banks, where noise propagation turns vigilant monitoring into vexing guesswork, bloating debug cycles and safety audits. The Schneider Electric 140DDI35300 tackles this as a 32-channel discrete input module for Modicon Quantum platforms, precision-built to ingest 24V DC sink signals with group-wise safeguards, channeling raw field states into the PLC’s data stream with the clarity needed for seamless sequencing.

- 140DDI35300

- 140DDI35300

This module asserts itself in dense architectures like assembly automation, where it consolidates 32 points for robotic gripper confirms without slot sprawl, or in bulk solids processing for silo level discretes amid vibratory feeders. Lacking such density and protection, crews daisy-chain unprotected commons, inviting common-mode faults that idle zones and inflate panel footprints. The Schneider Electric 140DDI35300 simplifies with 4×8 channel partitioning, each fused for independent resilience while rejecting 50/60 Hz hum—foundations of industrial automation’s “discrete input module,” “Quantum I/O sink,” and “24V DC process control.” It arms with per-group LED diagnostics, illuminating faults for swift isolates rather than system sweeps. At root, it’s the gatekeeper for operations where input integrity is inviolable—fusing field frenzy to logic lucidity, so your Quantum core commands with conviction, not conjecture.

Embedded in the Modicon Quantum’s I/O lattice, the Schneider Electric 140DDI35300 functions as a vigilant aggregator, latching into rack slots 2-16 to harvest discrete pulses from the plant floor via the backplane’s embrace. It draws 500 mA at 5 VDC from the bus, rousing 32 isolated sink inputs grouped in 4×8 arrays that swallow 24 VDC wets from pushbuttons or photoeyes—each with 2.5 kΩ impedance for 8 mA nominal draw, settling states in 1 ms while the onboard fuses (one per octet) sever shorts without collateral. Imagine a palletizer’s stack detect on channel 12: the field +24 VDC grounds through the input to common, flipping the bit in the PLC’s %I table, all while 1500 Vrms group-to-bus isolation buffers against drive di/dt kicks.

This rapport ripples through the ranks—upstream, it syncs with redundant PSUs for glitch-free polls; downstream, it feeds fiber-linked drops or Ethernet CPUs via Modbus, with broken-wire detection per channel routing anomalies to the rack’s fault bus for SCADA summons. Diagnostics gleam via a 40-pin terminal block and octet LEDs (green for active, off for open), with register-mapped health words queryable in Unity Pro for trending. In backplane-burdened Quantum frames, slot it proximal to outputs for loop symmetry, or remote via CRA adapters for edge enclosures; its limiting resistors and 200 µA leakage cap clamp leakage in off states, upholding Quantum’s scan sovereignty. For assemblers, it’s intuitively insertable: torque the commons at 1 Nm, verify polarity with a loop tester, and it auto-addresses in the config, offloading debounce to firmware so your process control captures with calibrated candor, not capricious catches.

| Specification | Details |

|---|---|

| Model Number | 140DDI35300 |

| Brand | Schneider Electric |

| Type | 32-Channel Discrete Input Module |

| Input Voltage | 24 V DC (19.2-30 V) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | Quantum Rack |

| Dimensions | 170mm x 48mm x 280mm |

| Weight | 0.45 kg |

| Interface/Bus | Modicon Quantum Backplane |

| Compliance | CE, UL, RoHS |

| Supported Protocols | Modbus (via Rack) |

| Typical Power Draw | 500 mA @ 5V |

Deploying the Schneider Electric 140DDI35300 cultivates a cornerstone of capture confidence, its 4×8 fused partitioning sustaining 32 states sans single-point sabotage—imperative for feeder lines, where a blown common idles 8 sensors and 15% output lulls. This segmentation spawns systemic stability: inputs hold logic amid thermal flux, forestalling the 1% chatter drift in variable apps and etching edge captures to 1 ms for sequence safeguards that streamline SIL audits with ease.

The advantages amplify in array acuity; consolidating 32 channels shrinks slot counts by 35%, easing enclosure economies and wiring weaves, while group fuses enable hot-swap quadrants without rack resets, unbinding cycles for baseline benchmarks like cycle counts in indexers. Engineering envelopes expand too—sink logic meshes legacy PNP sensors sans inverters, and 1500 Vrms barriers expedite EMC nods for hazardous zones without extras. Across spans, it tempers turnarounds—MTBF vaults 220,000 hours absent fuse fatigue, rerouting techs from fault flurries to flow fosters, where dense discretes drive emulations for preemptive proofs. For the Schneider Electric 140DDI35300, capture is consummate: it corrals chaos from cacophonous to coherent, where input influx ignites industrial intents unimpugned by intermittence’s ire.

The Schneider Electric 140DDI35300 insinuates in infrastructures where discrete deluge demands discipline, such as in electronics assembly, where it aggregates pick-and-place verifies over 32-channel spans, its sink tolerance taming ESD from wafer handlers for placement precisions that curb misfeeds and critical system uptime in process control environments. Chemical metering skids enlist it for valve proves in corrosive cloaks, grouping 4×8 for flow switch polls amid pump pulse—fuses isolate brine shorts, locking dosing loops to 0.5% variances without drift.

Elevator banks embed it for door interlocks, backplane-linking 28 stations for position discretes under seismic sway, where LED diagnostics preempt jam alerts that strand cars for spans. These infusions intimate its import: from solder-smoked stations to sump-swept sumps, the Schneider Electric 140DDI35300 disciplines industrial automation’s discrete domain, where input’s imperative is inexorable integrity.

140DDI35310 – Source logic counterpart for PNP sensor-heavy fieldbus integrations

140DDI36400 – 96-channel high-density variant for ultra-compact discrete farms

140DDI85300 – Wide-range 10-60 VDC sink alternative for mixed-voltage legacy drops

140DAI35300 – AC input 24 VAC 4×8 module for relay contact monitoring

140AMM09000 – Mixed analog/digital hybrid for balanced I/O small-form needs

140OIS31000 – Output interface sibling for closed-loop discrete feedback

ASMBP20 – Fiber MBM extender for remote input clusters in Quantum networks

Before baying the Schneider Electric 140DDI35300 in your Quantum rack, assay the backplane for terminal debris—a soft brush with IPA swab clears grit that could arc commons by 50 mV. Group wiring warrants watch: for sink mode, tie field commons to +24 VDC per octet and verify <1 V drop with a milli-voltmeter under 8 mA loads, lest polarity flips invert states on shared buses. Bus budget is binding—cap drops at 6 A aggregate, as excesses ebb rails below 4.75 V, muting polls; Unity’s I/O planner parses this pre-place. Affix 30 mm lateral leeway, as stacked slots in 60°C cabinets court crosstalk from adjacent heat.

Maintaining its mettle mandates methodical monitors, not marathons. Monthly, mine the status word via Modbus for fuse bits—blown octets blank LEDs, so bench a 1 kΩ pull-up per suspect to confirm and docket spares. Quarterly, continuity-scan the 40-pin block with a megohmmeter for >10 MΩ insulation, and in dusty domains, sheath terminals with dielectric gel post-purge to rebuff residue ramps. Annually, pulse-test response: toggle 24 VDC squares and scope edges below 1 ms, chasing baselines and filing latency logs for lag lures; Schneider’s test harness hastens this from the faceplate. In vibratory venues, semi-annual torque tallies on fuse holders at 0.5 Nm thwart walk-offs, but rack-cycle post-clamp to cleanse caches. These drills, drawn from duty diaries, deflect 81% of input incursions, dignifying the Schneider Electric 140DDI35300 as your discrete defender.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626