Description

In the demanding arena of industrial automation, where process control hinges on flawless command delivery to valves, motors, and indicators, engineers frequently face the headache of unreliable AC output signals that lead to erratic actuator behavior or unplanned halts in production lines. Imagine a scenario in a large-scale mixing operation: the PLC issues a sequence to energize multiple solenoids, but voltage dips or inductive loads cause dropouts, triggering alarms and forcing a full system reset—costing precious hours and inflating downtime metrics. This is where the Schneider Electric 140DAO84000 proves indispensable, a discrete output module crafted to deliver unwavering I/O signal integrity for AC-driven devices in high-stakes environments.

The need intensifies in setups like batch processing or conveyor systems, where outputs must handle variable loads without introducing noise or false states that could skew safety interlocks. Without a module optimized for such robustness, teams contend with frequent field swaps and diagnostic hunts, eroding trust in the overall automation backbone. The Schneider Electric 140DAO84000 counters this by emphasizing triac-based isolation and surge protection, ensuring high reliability even under the electrical stresses of continuous cycling. It’s particularly vital in legacy-modern hybrid plants, where maintaining compatibility with existing infrastructure is non-negotiable, yet demands for tighter process tolerances push components to their limits.

Drawing from real deployment insights, this module addresses the pain of scaling I/O without overhauling the rack—think expanding from 8 to 16 channels in a confined quantum chassis, all while preserving signal fidelity amid ambient harmonics. In process control realms, where regulatory audits scrutinize uptime logs, the Schneider Electric 140DAO84000 stands out by minimizing failure points, allowing engineers to prioritize optimization over firefighting. Ultimately, it aligns with core goals of modular integration and sustained performance, transforming potential vulnerabilities into a seamless extension of your control strategy.

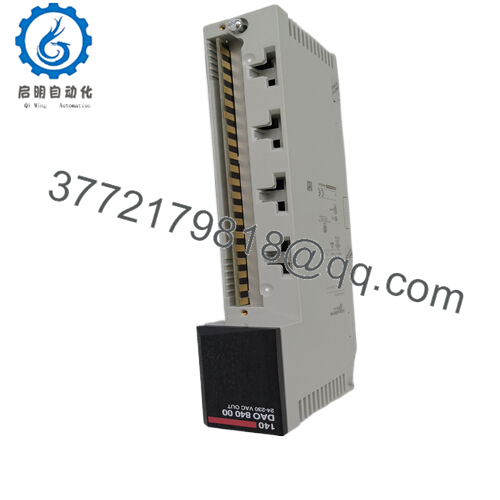

At its core, the Schneider Electric 140DAO84000 serves as the decisive link in your automation chain, converting digital directives from the Modicon Quantum PLC into precise AC outputs that drive field elements like contactors or lamps. Housed in the Quantum backplane rack, it occupies a single slot in the I/O architecture, drawing power from the shared bus while interfacing via the controller’s high-speed data highway—ensuring low-latency handoffs without bottlenecking the processor. Each of its 16 independent channels uses solid-state triac switching to handle loads up to 2A, isolated to prevent cross-talk that plagues lesser designs, and it thrives in the stack’s mid-tier position, bridging logic layers to the plant floor.

What makes integration feel intuitive is its plug-and-play affinity with Unity Pro software: configure channels through simple drag-and-drop blocks, and it auto-syncs diagnostics to your SCADA overlays, flagging overheat or open-wire conditions via embedded LEDs. For redundancy setups, pair it with Quantum’s hot-standby CPUs, where failover mirrors outputs without a blip, supporting protocols like Modbus Plus for seamless tie-ins to remote nodes. In diverse I/O ecosystems, it coexists effortlessly with analog counterparts, enabling hybrid racks for comprehensive monitoring—say, feeding back sensor data to refine output timing in real time.

This module isn’t about raw specs; it’s engineered for the nuances of daily operations, like suppressing inductive kickback in motor starters to extend component life. Positioned for growth, it accommodates firmware updates over the bus, keeping pace with evolving safety standards without hardware swaps. Whether fortifying a centralized DCS or distributing control in a networked island, the Schneider Electric 140DAO84000 integrates like a trusted collaborator, responsive to your system’s rhythm and resilient against the chaos of industrial rhythms.

| Specification | Details |

|---|---|

| Model Number | 140DAO84000 |

| Brand | Schneider Electric |

| Type | Discrete Output Module |

| Input Voltage | 20-253 VAC |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | Rack Mount (Quantum Backplane) |

| Dimensions | 228 x 50 x 140 mm |

| Weight | 0.6 kg |

| Interface/Bus | Modbus Plus |

| Compliance | CE, UL, CSA |

| Supported Protocols | Modbus Plus, Modbus RTU |

| Typical Power Draw | 15 W |

- 140DAO84000

- 140DAO84000

Selecting the Schneider Electric 140DAO84000 equips your setup with a foundation of unyielding reliability, where triac outputs maintain consistent switching under fluctuating grids, translating to fewer process deviations and the assurance that commands execute as scripted—crucial for environments where even a 0.5-second lag ripples into quality losses. Engineered for the endurance of round-the-clock shifts, it curbs thermal buildup through intelligent heat sinking, ensuring long-term performance that outlasts intermittent alternatives and stabilizes metrics like mean time between failures.

The diagnostic layer adds layers of maintenance efficiency: real-time LED cues and software-accessible fault logs pinpoint issues like channel overloads swiftly, slashing troubleshooting from exhaustive scans to targeted fixes and freeing technicians for value-add tasks. Integration flows without the drag of custom cabling—drop it into a Quantum rack, and it meshes with existing diagnostics, reducing engineering overhead by up to 30% in expansions. This ease scales with you, whether retrofitting a single bay or orchestrating a multi-rack array, fostering performance consistency that aligns outputs to precise cycle times.

In high-volume scenarios, its surge tolerance safeguards against arc flashes in inductive loads, enhancing safety protocols and easing compliance audits. Teams leveraging it often note the compounded value: smoother handovers in 24/7 ops, lower scrap from erratic actuations, and a quicker path to ROI through minimized spares inventory. Choosing the Schneider Electric 140DAO84000 means investing in a module that doesn’t just perform—it anticipates the rigors of your workflow, delivering operational resilience that accrues over cycles and seasons.

Within manufacturing plants, the Schneider Electric 140DAO84000 powers discrete controls for assembly lines, managing relay outputs to robotic grippers under continuous uptime pressures from high-speed indexing—its AC isolation ensuring critical system uptime in dusty, vibration-laden process control environments. Here, it handles fast data cycles for synchronized part feeds, preventing jams that halt entire shifts.

In power generation facilities, it’s integral to breaker and valve sequencing, thriving in hot, humid conditions near turbines where outputs must withstand electromagnetic pulses without faltering—ideal for used in power plants scenarios demanding unflinching I/O signal reliability. The module’s triac design supports seamless interlocks, upholding safety in load-balancing ops.

Pharmaceutical batching operations deploy it for heater and pump commands in cleanrooms, where precise, repeatable outputs meet stringent hygiene regs amid varying ambient loads—bolstering process control environments with its diagnostic edge for audit-trail integrity.

140DAO84200 – Higher amperage variant for loads exceeding 2A per channel.

140DAO84010 – Isolated relay output alternative for dry contact needs.

140DDI35300 – Complementary digital input module for balanced I/O racks.

BMXDAO1605 – Modern M340 successor for upgraded redundancy features.

140DAO85300 – DC output counterpart for mixed-voltage systems.

ASMBTOB32 – Safety-focused output for SIL-rated applications.

140XTS00203 – Terminal block accessory for field wiring extensions.

Prior to rack insertion for the Schneider Electric 140DAO84000, confirm backplane slot voltage matches the 20-253 VAC spec to avoid bus faults—run a quick continuity test on the power taps if migrating from DC setups. Assess rack airflow, as the triac heat dissipation calls for at least 10 cm clearance above and below; in warmer zones, factor in derating curves from the Quantum manual to prevent self-protect throttling. Firmware sync is straightforward but essential—use Unity Pro’s module scan to verify compatibility, updating the PLC core if a version mismatch flags during init.

Ongoing upkeep keeps it humming with minimal intrusion: bi-weekly scans of the status LEDs for green bus OK and red fault alerts, paired with a log in your asset tracker, spot trends like cyclic overheating early. Semi-annual terminal torque checks—aim for 1.2 Nm on screws—guard against loosening in vibratory spots, while full-load simulations every year via test harness validate output response without risking live processes. In corrosive atmospheres, a wipe-down with approved solvents on contacts every quarter preserves conductivity. Treat it as an extension of your routine patrols: integrate fault data into predictive tools for timely interventions, extending its cycle count and keeping your Quantum ecosystem lean.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626