Description

In the intricate web of industrial automation, where central controllers must orchestrate distant field devices without latency or data loss, engineers often wrestle with the constraints of cabling runs that stretch across factory floors or between buildings—leading to signal degradation, increased installation costs, and vulnerabilities to environmental disruptions. Envision a sprawling process control setup in a petrochemical complex: the main PLC rack issues commands to remote valve actuators half a kilometer away, but long coaxial lines pick up noise, causing intermittent dropouts that trigger safety shutdowns and erode operational trust. Enter the Schneider Electric 140CRP93100, a remote I/O head-end adaptor module that resolves these distributed architecture headaches by enabling reliable, extended-reach connectivity in Modicon Quantum systems.

This becomes crucial in scenarios like multi-zone manufacturing or utility substations, where centralizing all I/O at the core rack isn’t feasible due to space, heat, or hazard zones—pushing teams toward remote drops that demand robust head-end interfacing to maintain high reliability. Without such a bridge, setups suffer from fragmented networks, forcing expensive fiber conversions or frequent signal boosters that balloon engineering budgets. The Schneider Electric 140CRP93100 cuts through this by leveraging shielded coaxial cabling for up to 31 drops, each supporting generous I/O word counts, ensuring seamless data flow for high-density process control without compromising on diagnostics or uptime.

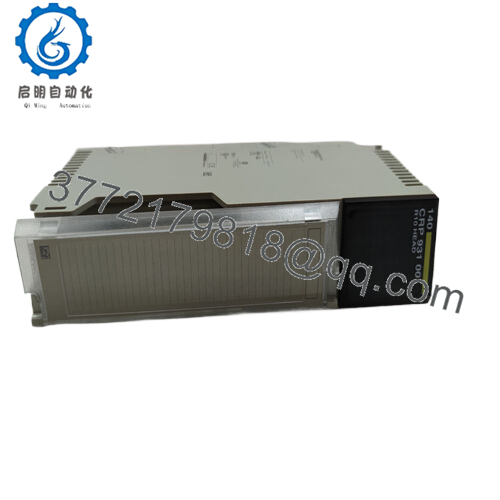

- 140CRP93100

- 140CRP93100

From a practical lens, it addresses the scalability pinch in growing facilities: as you add remote racks for localized monitoring, the module’s single-channel design integrates without rearchitecting the bus, preserving legacy investments while accommodating modern redundancy needs. In industrial automation contexts prone to electromagnetic interference or thermal variances, this adaptor fortifies the I/O signal pathway, letting you focus on refining control logic rather than chasing phantom faults. By prioritizing modular integration and fault-tolerant communication, the Schneider Electric 140CRP93100 empowers deployments that evolve with production demands, turning distributed challenges into strategic advantages.

Delving into its role within the automation stack, the Schneider Electric 140CRP93100 acts as the pivotal gateway in Quantum’s remote I/O architecture, anchoring the head-end to your central backplane while extending the network to outlying drops via a single coaxial connector. It slots directly into the Modicon Quantum rack—typically alongside the CPU and power supply—drawing bus current to manage polling cycles that query up to 31 remote modules over distances up to 3 km, all without taxing the main processor’s cycles. This positioning keeps it upstream in the I/O hierarchy: the PLC core dispatches commands through the adaptor’s LAN controller, which serializes them into a deterministic protocol, then fans them out to field drops housing discrete or analog I/O for real-time actuation and sensing.

Interaction feels collaborative rather than clunky; it supports Unity Pro’s configuration tools for drop mapping and addressing, with built-in diagnostics that self-check memory and power on startup, relaying status via rack LEDs or SCADA overlays—think amber flashes for cable faults or green for solid links. In redundancy configurations, pair it with a duplex setup for seamless failover, where a secondary head-end mirrors traffic without process interruption, and it embraces Modbus Plus for hybrid networks, bridging to legacy islands effortlessly. Positioned for the mid-stack realities, it handles 64 input/output words per drop, enabling dense remote racks that consolidate sensors and effectors without the sprawl of point-to-point wiring.

The beauty lies in its understated adaptability: no proprietary tools required for basic polls, just standard ladder rung assignments that treat remote I/O like local extensions. Whether bolstering a single-head-end chain in a compact plant or daisy-chaining multiples for zoned control, the Schneider Electric 140CRP93100 weaves into your ecosystem with minimal reconfiguration, supporting hot-plug drops for maintenance windows that don’t halt the line. It’s crafted to anticipate the flux of industrial ops—vibration on the cable run, spikes from nearby welders—delivering consistent throughput that keeps your control narrative coherent from rack to remote.

| Specification | Details |

|---|---|

| Model Number | 140CRP93100 |

| Brand | Schneider Electric |

| Type | RIO Head-End Adaptor Module |

| Input Voltage | 5 VDC (from backplane) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | Rack Mount (Quantum Backplane) |

| Dimensions | 228 x 50 x 140 mm |

| Weight | 0.5 kg |

| Interface/Bus | Coaxial (RIO Network) |

| Compliance | CE, RoHS, REACh |

| Supported Protocols | Modbus Plus, RIO |

| Typical Power Draw | 3 W |

Deploying the Schneider Electric 140CRP93100 unlocks a cascade of operational steadiness, where its coaxial isolation—rated to 500V DC—shields against ground loops that plague extended runs, yielding signal fidelity that sustains precise process control over kilometers and trims the risk of cascading errors in multi-drop chains. Built for the persistence of 24/7 regimes, it ensures long-term performance through low-dissipation electronics that resist thermal drift, allowing remote I/O to mirror local responsiveness and stabilizing metrics like cycle jitter in high-throughput loops.

Maintenance rhythms lighten considerably with its proactive diagnostics: onboard checks surface cable integrity or drop health in seconds via software queries, condensing fault hunts from rack-wide scans to pinpointed verifications and reallocating tech time to upgrades over upkeep. The integration’s subtlety shines in expansions—add a drop without bus reprograms, and it auto-accommodates, curbing engineering overhead by streamlining network provisioning and easing transitions from centralized to distributed topologies. This fluidity scales reliably, whether retrofitting a legacy Quantum or greenfielding a zoned DCS, fostering performance consistency that aligns remote actions to central intent without the drag of latency variances.

Safety and sustainability weave in naturally: its compliance footprint minimizes environmental audits, while the single-cable elbow connector simplifies field routing to cut installation waste. Users often highlight the accrued value in quieter ways—fewer nuisance trips from noise, smoother scaling for seasonal loads, and a leaner spares strategy since head-ends outlast cabling wear. Embracing the Schneider Electric 140CRP93100 means fortifying not just connections, but the foresight in your automation fabric, where distributed reach becomes a multiplier for efficiency rather than a multiplier for headaches.

In oil refineries, the Schneider Electric 140CRP93100 bridges central control rooms to remote pump stations, managing I/O signals across hazardous zones with coaxial resilience against EMI—critical for continuous uptime in process control environments where a dropped command could idle distillation towers. It supports up to 31 drops for layered monitoring, ensuring high reliability in explosive atmospheres.

Water utilities deploy it for distributed SCADA over reservoir networks, handling fast data cycles from level sensors to actuators in damp, expansive sites—used in wastewater management setups where extended cabling weathers corrosion, yet the module’s diagnostics uphold critical system uptime without frequent site treks.

Food processing plants leverage it for zoned conveyor controls, linking main PLCs to remote packaging lines amid washdown conditions; its drop capacity enables dense I/O for synchronized fills, thriving in high-reliability demands that keep production flowing seamlessly.

140CRP93000 – Dual-channel variant for parallel RIO networks in high-availability setups.

140XTS00203 – Coaxial cable accessory for extended drop connections up to 3 km.

140CRP93200 – Fiber optic head-end alternative for EMI-heavy environments.

ASMBTOE232 – Ethernet bridge module for modern IP-based remote expansions.

140DDI35300 – Paired digital input drop for input-heavy remote racks.

BMXRIO001 – M340-compatible RIO adaptor for hybrid Quantum migrations.

140DAO84000 – Complementary output module for balanced remote I/O configurations.

As you gear up to integrate the Schneider Electric 140CRP93100, start by auditing your Quantum rack’s slot availability and bus loading—aim for under 80% utilization to buffer the 600 mA draw, and cross-reference the coaxial connector’s elbow orientation against panel depth to avoid crimp issues. Probe the intended cable run for impedance mismatches; a TDR test on the line flags reflections early, preventing ghost drops post-install. Firmware alignment matters too—boot the Unity Pro scanner to confirm the adaptor’s version syncs with your CPU, patching any deltas via the backplane loader to dodge init stalls.

Maintenance evolves into a measured cadence once operational: weekly polls of the LAN status LED for link stability, logged against drop response times in your historian, reveal cable wear before it bites. Biannual connector reseats and shield continuity checks—using a low-voltage ohmmeter—counter oxidation in humid vaults, while full-network simulations annually via test drops validate polling under load sans live disruption. In dusty or saline exposures, a non-abrasive wipe on the female port every four months preserves contact quality. Frame it as embedded vigilance: feed diagnostic streams into your CMMS for anomaly baselines, transforming routine checks into a predictive shield that prolongs the head-end’s tenure amid evolving plant dynamics.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626