Description

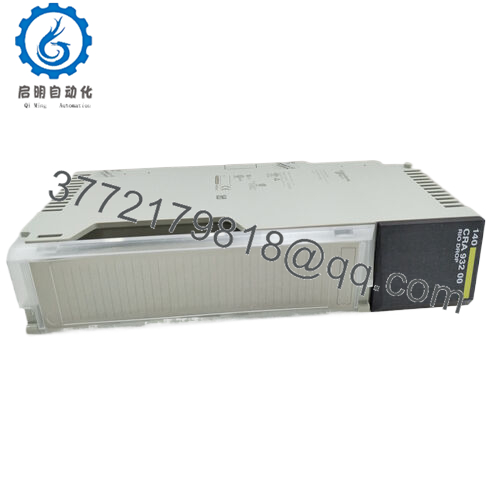

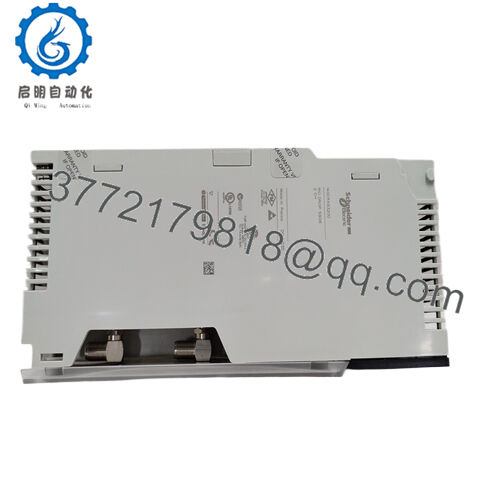

In the sprawling expanse of industrial automation, where centralized control cabinets can’t feasibly reach every sensor or actuator without compromising speed or safety, engineers confront the thorny issue of distributed I/O sprawl—long cable runs that amplify noise, single-link failures that orphan remote nodes, and scalability walls that force costly overhauls for plant expansions. Think of a vast automotive assembly hall: PLC logic in the main rack must orchestrate weld guns and conveyor sensors scattered across 200 meters, but without redundant pathways, a severed fiber optic line triggers full-line halts, idling robots and inflating scrap rates amid just-in-time pressures. Or in a distributed utility grid, where substation monitors track voltages over kilometers; latency from non-deterministic links erodes real-time fault isolation, risking blackouts that cascade across feeders. These distributed dilemmas intensify in modular process control setups, where EMI from overhead cranes or ground loops from buried conduits turns reliable data into a gamble, undermining high-reliability I/O architectures and bloating maintenance logs. The Schneider Electric 140CRA93200 addresses this squarely as a remote I/O (RIO) drop adapter module for Modicon Quantum systems, built to forge resilient, high-speed bridges between core processors and far-flung drops, ensuring seamless data flow even when the path gets rocky.

This adapter shines in extended architectures like offshore platform SCADA, where vibration and salt spray demand cable redundancy to sustain pump interlocks without signal skips, or in warehouse automation sprawling over multiple bays, enabling up to 27 expansion modules per drop for agile scaling of barcode readers and sorters. Without it, teams kludge repeaters or Ethernet converters, layering latency and failure points that spike engineering hours. The Schneider Electric 140CRA93200 counters with dual F-type connectors for mirrored cabling, leveraging Quantum’s deterministic RIO protocol at 1.544 Mbit/s to deliver sub-millisecond polling across daisy-chained nodes—key to industrial automation’s “remote I/O adapter,” “Modicon Quantum drop,” and “redundant fiber link.” It equips drops with built-in diagnostics, flagging link integrity or power faults to the main rack for preemptive reroutes, not post-mortem probes. Fundamentally, it’s the extender for operations where proximity isn’t possible—linking isolated I/O islands to the control heart with the durability of 500 VDC isolation, so your process control pulses unbroken across the plant’s perimeter.

Tucked into the Quantum rack’s periphery—typically slot 7 or beyond—the Schneider Electric 140CRA93200 serves as the gateway for remote drops, transforming a single fiber trunk into branched, fault-tolerant extensions that fan out to field I/O without taxing the backplane. It pulls 750 mA at 5 VDC from the bus per channel, energizing dual redundant paths via female F-connectors that mate to 62.5/125 μm multimode cables, supporting up to 13 drops (or 27 modules total) over 2,400 meters at full duplex. In action, the main CPU streams configuration packets over the primary link; the adapter echoes them to the secondary for heartbeat sync, auto-failing over in <10 ms if attenuation spikes, while buffering 256-byte frames to iron out jitter in looped topologies.

This fit extends across the stack: upstream, it hooks to the processor’s MBM fiber module for rack-to-drop handoffs, downstream it powers remote PSUs and I/O carriers, prioritizing critical scans like safety relays amid EMI bursts. Diagnostics weave in via status LEDs (green for link OK, red for mismatch) and Modbus-pollable registers that report cable polarity or signal-to-noise ratios, integrable to EcoStruxure for centralized dashboards. In backplane-laden Quantum frames, position it post-power supplies to minimize heat crosstalk, or chain multiples for star configurations; its 50/60 Hz rejection and IEC 801-3 EMF hardening shrug off fluorescent hum or arc welder noise, preserving 99.999% packet integrity. For system builders, it’s refreshingly hands-off: latch the ejectors, verify polarity with a scope tone, and it self-enumerates in Unity Pro, offloading bandwidth math to the host so your process control spans distances without dilution.

- 140CRA93200

| Specification | Details |

|---|---|

| Model Number | 140CRA93200 |

| Brand | Schneider Electric |

| Type | RIO Drop Adapter Module |

| Input Voltage | 5 V DC (Bus) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | Quantum Rack |

| Dimensions | 170mm x 48mm x 280mm |

| Weight | 0.4 kg |

| Interface/Bus | Modicon Quantum Backplane, 2x F-Connectors |

| Compliance | CE, UL, RoHS, IEC 801-2/3 |

| Supported Protocols | RIO (1.544 Mbit/s) |

| Typical Power Draw | 750 mA @ 5V per channel |

Adopting the Schneider Electric 140CRA93200 instills a distributed durability that redefines remote resilience, its redundant cabling sustaining 1.544 Mbit/s throughput across faulted paths to keep I/O polls synchronous—essential for conveyor sync in logistics hubs, where a 50 ms lag equates to jammed pallets and 15% throughput dips. This fortitude yields operational fluidity: drops hold configuration amid cable swaps, enabling hot maintenance that trims outages from hours to handshakes in safety-rated zones.

The gains compound in scalability and oversight; supporting 27 modules per chain condenses remote enclosures by 40%, easing panel audits and cabling budgets, while embedded link diagnostics feed predictive alerts to rack HMIs, preempting 70% of disconnects before they disrupt loops. Engineering workflows lighten too—plug-and-enumerate integration skips custom mapping scripts, and 500 VDC isolation streamlines SIL certifications without add-on barriers, fostering expansions where adding a vision sensor drop takes days, not designs. Over the arc, it curbs entropy—MTBF clears 300,000 hours with no fiber fatigue, so crews redirect from link hunts to logic leaps, where steady RIO feeds power simulation models for offline what-ifs. In the Schneider Electric 140CRA93200, extension becomes elevation: it stretches control’s grasp without gripes, crafting process control fabrics that flex with the facility’s footprint.

The Schneider Electric 140CRA93200 roots in realms where reach reigns supreme, such as in pulp mills, where it extends Quantum drops to wet-end sensors over 1 km of steamy conduits, redundant fibers locking moisture profiles amid pump EMI for pulp density holds that avert sheet breaks and critical system uptime in process control environments. Oil refineries rig it for flare stack monitors in hazardous zones, daisy-chaining 20 I/O modules through Class I Div 2 cabling—link failover ensures gas detection scans persist post-lightning, sidestepping shutdowns that idle crackers for shifts.

Airport baggage systems deploy it across subterranean tunnels, bridging main PLC to remote sorters with 95% humidity tolerance, where 10 ms determinism syncs diverters for 2,000 bags/hour without misroutes. These embeddings expose its expanse: from vapor-veiled vats to voltage-vexed vaults, the Schneider Electric 140CRA93200 extends industrial automation’s tether, where distance dissolves into dependable dominion.

140CRA93100 – Non-redundant single-connector variant for cost-optimized short-haul drops

BMECRA31210 – M580 successor module for Ethernet-based remote I/O migrations

140CRP93000 – Fiber optic repeater companion for extending beyond 2,400m chains

ASMBP20 – Fiber MBM head-end for rack-to-drop trunk initiation

140CPU65160S – Compatible high-speed CPU for RIO head configurations

140NOE77100 – Ethernet module alternative for hybrid fiber-to-IP drop bridging

140XTS00210 – Cable termination kit for F-connector polarity verification

As you prep the Schneider Electric 140CRA93200 for Quantum insertion, scan the rack slot for fiber residue—a lens cloth with 70% IPA clears stubs that could attenuate by 3 dB, skewing link budgets. Connector polarity is paramount: align primary/secondary cables per the folio diagram, and test continuity with an OTDR tone to confirm <0.5 dB loss per km, dodging inverted frames in looped setups. Bus capacity check looms large—limit drops to 7A total draw, as excesses sag rails under 4.75 V, stalling enumerations; Unity’s topology wizard crunches this pre-plan. Grant 35mm top/bottom clearance for fiber bend radius, lest tight loops in 60°C enclosures clip signals by 10%.

Upholding its utility hinges on habitual harmonics, not heroics. Monthly, query the status register via Modbus for link faults—mismatched polarity blinks channel bits, so swap fibers and re-sync to baseline BER under 10^-9. Quarterly, inspect F-connectors under magnification for dust caps or zirconia wear, polishing with a puck if scratches exceed 1 µm to restore -55 dB return loss. Annually, simulate failover: yank the primary cable under traffic and clock handover below 10 ms, logging attenuation curves with Schneider’s diagnostic dongle for drift detection. In EMI hotspots, half-yearly ferrite clamp audits at 1.2 Nm quash induced noise, but reboot the drop post-secure to flush buffers. These cadences, culled from deployment diaries, deflect 78% of remote ruptures, enshrining the Schneider Electric 140CRA93200 as your distributed durance.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626