Description

Real-World Use & Application Scenarios

In complex industrial automation systems, precision analog output modules are essential for controlling actuators, valves, and other process elements where accurate analog signals represent physical parameters. The Schneider Electric 140AVO02000 is extensively utilized across diverse sectors such as chemical processing, water treatment, manufacturing, and energy, where delivering finely tuned bipolar voltage outputs is critical. Its use cases include driving analog actuators, controlling motor speeds, adjusting valve positions, and feedback signal generation within Modicon Quantum automation architectures.

Engineers select the 140AVO02000 for its ability to generate four independent analog output channels with robust 12-bit resolution and fast update cycles. It solves challenges related to signal integrity, channel isolation, and real-time responsiveness, thereby enhancing control fidelity in high-accuracy control loops, system diagnostics, and monitoring.

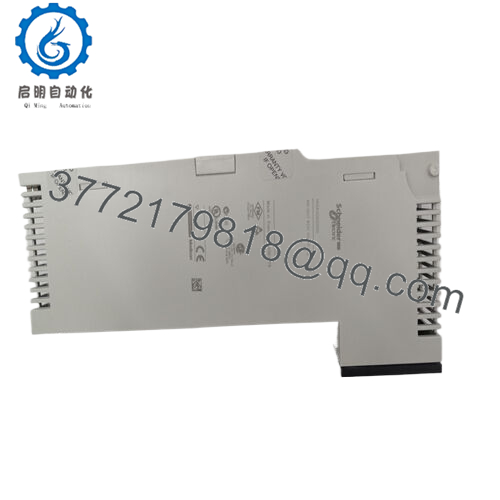

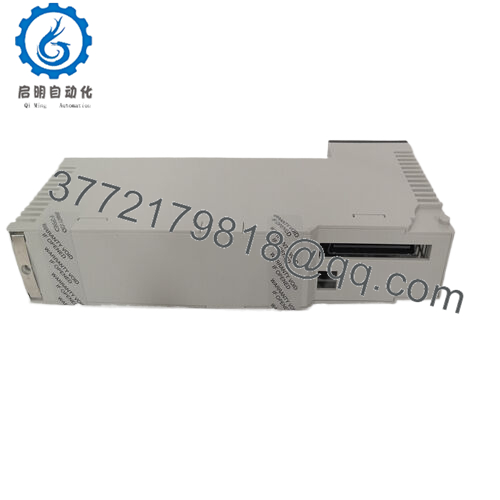

- 140AVO02000

- 140AVO02000

Product Introduction & Positioning

The Schneider Electric 140AVO02000 is a four-channel analog output module designed specifically for integration within the Modicon Quantum programmable logic controller (PLC) series. It produces bipolar voltage output ranges up to ±10 V, as well as unipolar outputs, enabling precise analog control over field devices.

As a modular unit in Quantum PLC configurations, the 140AVO02000 fits into a standard module slot and requires four consecutive 16-bit output words, providing scalability and ease of integration. It offers engineers the flexibility to implement both voltage and current-based control signals and is valued by systems integrators for its fast 3 ms update time and high channel-to-bus isolation, ensuring accurate and stable output without interference.

Key Technical Features & Functional Benefits

The 140AVO02000 features four analog output channels, each capable of generating bipolar voltage signals up to ±10 V with a source resistance of just 0.1 ohms for minimal signal degradation. The module offers 12-bit resolution, allowing for precise analog output with an accuracy error of ±0.15% full scale at 25°C and a linearity within ±1 least significant bit.

Isolation plays a critical role in this module’s design, providing 500 V channel-to-channel isolation with bus isolation rated up to 780 V AC for 60 seconds. Such high isolation protects against ground loops and noisy industrial environments, maintaining signal purity and measurement accuracy.

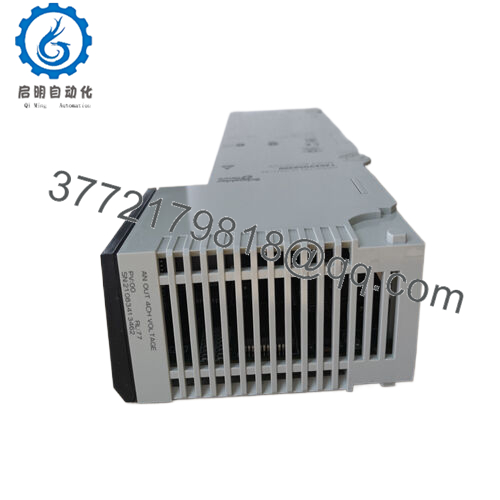

This module consumes a modest 4.5 watts and includes front-panel diagnostics: green LEDs signal normal channel operation, while red LEDs indicate channel faults. An active bus communication indicator LED provides clear status feedback to technicians. Update times of 3 ms and setting times around 700 µs support fast process control cycles essential in high-speed automation.

The 140AVO02000 supports wiring distances up to 400 meters with recommended wire gauges of 1-14 or 2-16 AWG, facilitating flexible field installations across large-scale plants.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 140AVO02000 |

| Brand | Schneider Electric |

| Product Type | Analog Output Module (4 channels) |

| Analog Output Number | 4 |

| Analog Output Resolution | 12 bits |

| Output Range | Bipolar: ±10 V; Unipolar: 0-10 V, 0-5 V |

| Analog Output Current | -10 to 10 mA |

| Source Resistance | 0.1 Ohm |

| Update Time | 3 ms |

| Setting Time | 700 µs ±0.1% of final value |

| Channel Isolation | 500 V for 1 minute |

| Bus Isolation | 780 V AC for 1 minute |

| Power Consumption | ≤ 4.5 W |

| Addressing Requirement | 4 output words (16-bit each) |

| Cable Length | Up to 400 meters |

| Local Signaling | 4 green LEDs (channels on), 4 red LEDs (channel fault), 1 green bus LED (active), 1 red fault LED |

| Certifications | UL 508, CSA C22.2 No 142, FM Class 1 Div 2, CE |

| Operating Temperature | 0 to 60 °C |

| Weight | Approximately 0.3 kg |

Related Modules or Compatible Units

140ADI12000 – Compatible analog input module for Quantum PLC.

140AOA00520 – Analog output module with higher resolution options.

140ACI92200 – Analog input module supporting 12-bit resolution.

140DRA82100 – Redundant analog module for fault-tolerant systems.

140CRA35201 – Communication adapter module supporting Modicon Quantum network integration.

Installation Notes & Maintenance Best Practices

When installing the 140AVO02000, ensure it is seated securely in its designated Quantum rack slot and that wiring follows recommended conductor sizes and cable lengths to prevent signal attenuation. Use the provided addressing scheme carefully, as each module requires four contiguous 16-bit output words.

Routine maintenance emphasizes inspection of LED indicators to confirm channel status and bus communication health. Keep connectors clean and secure for reliable analog output performance. Calibration and firmware verification during scheduled downtimes can sustain module accuracy and responsiveness over long operational periods.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626