Description

Real-World Use & Application Scenarios

In precision industrial environments where accurate temperature measurement is vital, the Schneider Electric 140ARI03010 analog input module plays a crucial role. This module is widely used in process industries such as chemical, pharmaceuticals, water treatment, and energy for monitoring temperature through connected resistance temperature detectors (RTDs). Accurate temperature monitoring helps maintain product quality, ensures safety compliance, and optimizes energy consumption. The 140ARI03010 is especially applicable in control systems built on the Modicon Quantum platform, where dependable, high-resolution data acquisition from multiple RTD inputs is essential for advanced process control and real-time diagnostics.

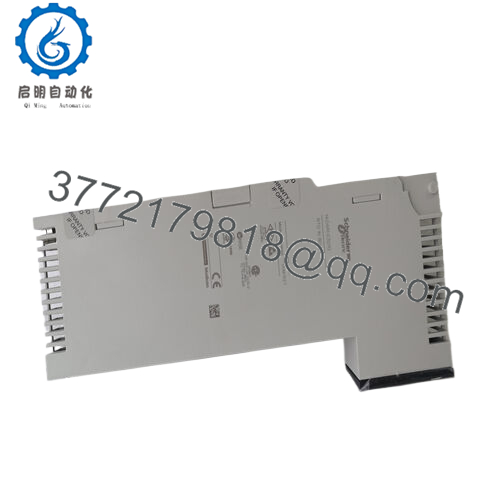

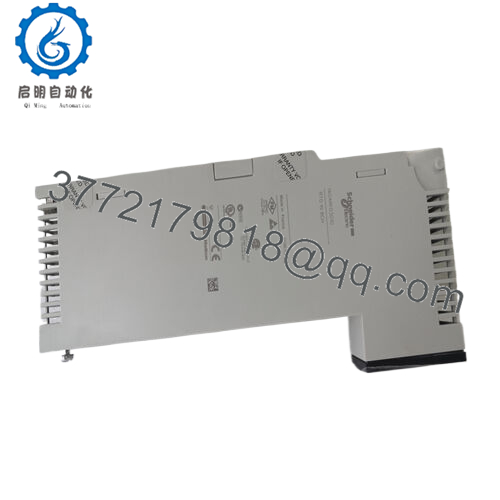

Product Introduction & Positioning

The Schneider Electric 140ARI03010 is an 8-channel analog input module designed for temperature measurement using RTDs, compatible with the Modicon Quantum PLC series. It supports differential inputs and interfaces with a broad range of temperature probes, including Pt and Ni types with current ratings of 0.5 mA and 2.5 mA, allowing versatility across different temperature measurement ranges.

- 140ARI03010

Sitting within the Quantum modular automation family, the 140ARI03010 provides precise, reliable data conversion with its high 13-bit resolution. Its dedicated design focuses on temperature accuracy, fast updating speeds, and robust channel isolation, making it a trusted choice for applications requiring fine temperature control and monitoring within distributed control systems.

Key Technical Features & Functional Benefits

The module offers eight differential input channels compatible with multiple RTD types, supporting a wide temperature range from -200 °C to 850 °C depending on the probe type. It delivers 13-bit input resolution which contributes to accurate temperature reading with a precision of 0.1 °C absolute accuracy and linearity better than ±0.01% full scale.

Isolation is robust with 1780 V AC between channels and bus, 2500 V DC bus isolation, and 300 Vrms channel-to-channel, safeguarding against interference and ensuring signal integrity in electrically noisy industrial environments. The module features diagnostic LEDs for each channel alongside fault and bus indicators, significantly simplifying troubleshooting protocols and preventative maintenance.

Update times are configurable from 640 ms for 2- and 4-wire setups to 1200 ms for 3-wire configurations, allowing engineers to balance between speed and signal stability as needed. Minimal power consumption of 1 W aids in reducing heat generation and operational costs.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 140ARI03010 |

| Brand | Schneider Electric |

| Product Type | Analog Input Module (Temperature RTD) |

| Number of Inputs | 8 Differential Channels |

| Supported Probes | Pt 100, Pt 200, Pt 500, Pt 1000; Ni 100, Ni 200, Ni 500, Ni 1000 |

| Input Current | 0.5 mA and 2.5 mA |

| Input Resolution | 13 bits |

| Temperature Measurement Range | -200 to 850 °C (varies by RTD type) |

| Absolute Accuracy Error | 0.1 °C |

| Linearity Error | ± 0.01% full scale |

| Accuracy Drift (0 to 60 °C) | ± 0.9 °C |

| Isolation Voltage | 1780 V AC (channels to bus), 2500 V DC (bus), 300 Vrms (channels) |

| Update Time | 640 ms (2/4 wire), 1200 ms (3 wire) |

| Fault Detection | Broken wire, out of range |

| Power Consumption | 1 W |

| Addressing Words | 9 input words |

| Local Signaling | 8 channel LEDs (green/red), 1 bus LED (green), 1 external fault LED (red) |

| Operating Temperature | 0 to 60 °C |

| Storage Temperature | -40 to 85 °C |

| Certifications | UL 508, CSA C22.2 No 142, FM Class 1 Div 2, CE |

| Weight | Approximately 0.3 kg |

Related Modules or Compatible Units

140AVO02000 – Analog output module for Modicon Quantum with four voltage output channels.

140ADI12000 – Analog input module supporting voltage and current inputs.

140DPN21100 – PROFIBUS communication card compatible with Quantum platforms.

140CPU65100 – Quantum CPU module for use with input/output modules like 140ARI03010.

140CRA35201 – Communication adapter module for Quantum networking.

Installation Notes & Maintenance Best Practices

Ensure the 140ARI03010 module is securely installed in the proper slot within a Modicon Quantum rack. Use appropriate cabling consistent with the RTD probe wiring (2, 3, or 4-wire configurations), and follow grounding recommendations to minimize electrical noise interference. The module requires a sequence of nine 16-bit input words to map data and status for the eight channels.

Regularly inspect channel LED indicators to quickly detect faults such as broken wires or out-of-range measurements. Clean and secure connectors as part of routine electrical maintenance. Calibration verification during scheduled outages helps maintain measurement precision over time.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626