Description

In the pulse-racing domain of industrial automation, where actuators and valves hinge on flawlessly modulated signals to avert overruns or stalls, control engineers wrestle with the specter of output inaccuracies—overshoots from load variations, scaling mismatches that skew actuator responses, or drift under sustained draws that destabilize entire loops. Visualize a cement kiln’s control suite: PLC commands fine-tune damper positions via 4-20mA feeds, but a module’s nonlinearity injects 0.5% errors, inflating fuel burn by 2% and risking clinker defects that cascade through quality gates. Or in a brewery’s fermentation hall, where proportional valves dose yeast nutrients; without multirange fidelity, you’re calibrating per batch type, layering custom attenuators that clutter cabinets and invite ground noise into high-reliability I/O paths. These frailties compound in EMI-saturated zones near grinders or pumps, where single-channel faults propagate to safety interlocks, eroding process control’s edge and inflating audit risks. The Schneider Electric 140ACO13000 dispatches this as an 8-channel multirange analog output module for Modicon Quantum systems, precision-forged to drive diverse loads with unyielding linearity, transforming digital decrees into analog actions that hold true across shifts.

Such versatility is non-negotiable in adaptive setups like plastics extrusion, where die pressures demand scalable currents from 0-25mA without hardware pivots, or in HVAC chillers sequencing compressor ramps amid seasonal loads. Devoid of this, squads cobble isolators or range extenders, ballooning footprints and failure modes while diluting command authority. The Schneider Electric 140ACO13000 demystifies with software-selectable spans, clamping linearity to ±4µA while sinking up to 30V loops—hallmarks of industrial automation’s “analog output module,” “multirange I/O driver,” and “process control actuation.” It layers channel-wise diagnostics, surfacing shorts or drifts to the bus for scripted halts, turning potential pitfalls into preempted pauses. At its core, it’s the executor for arenas where output exactitude isn’t aspirational—it’s the calibrated conduit from logic to leverage, empowering Quantum cores to command with conviction rather than concession.

- 140ACO13000

- 140ACO13000

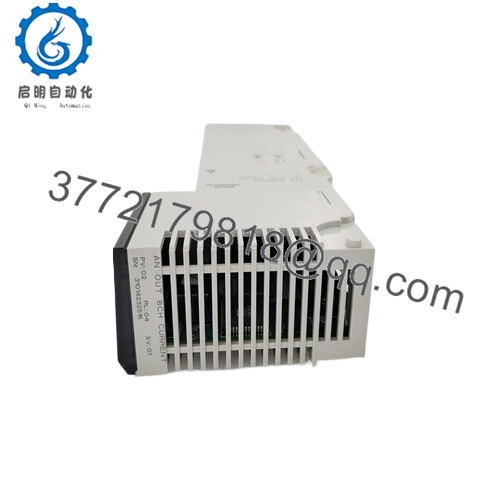

At the output vanguard of your Modicon Quantum assembly, the Schneider Electric 140ACO13000 materializes digital intent as analog current, latching into rack slots 2-16 to propel field effectors from the backplane’s embrace. It sips 400mA at 5VDC from the bus, rousing eight galvanically isolated channels that dispense 0-20mA, 4-20mA, or 0-25mA flows—toggled via Unity Pro registers, with each sinking loads up to 750Ω at 30V max. Envision a PID output on channel 3: the CPU writes a 16-bit value (0-16000 for 4-20mA), and within 5ms, it settles to 3.2ms precision, driving a pneumatic regulator sans settling ripple, all while the module’s optos buffer 500V transients from valve coils.

This synergy permeates the hierarchy—upstream, it draws from redundant PSUs for glitch-free ramps; downstream, it interfaces via 15-pin D-subs to shielded pairs, feeding Profibus drops or Ethernet I/O for remote valve manifolds. Diagnostics pulse through nine LEDs for bus OK and per-channel faults, with Modbus-accessible words flagging overcurrents or wire breaks, integrable to EcoStruxure for trending. In sprawling backplanes, nestle it adjacent to input siblings for closed-loop symmetry, or remote it via fiber MBMs for edge actuation; its 50/60Hz rejection filters motor-induced hash, upholding Quantum’s scan sovereignty. Integrators cherish the plug-and-forget: ejector-pin the card, ground the shields at 1Nm, and it auto-maps in the config tree, offloading loop tuning to the host for outputs that orchestrate, not obstruct, your process control cadence.

| Specification | Details |

|---|---|

| Model Number | 140ACO13000 |

| Brand | Schneider Electric |

| Type | 8-Channel Multirange Analog Output Module |

| Input Voltage | 5 V DC (Bus) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | Quantum Rack |

| Dimensions | 170mm x 48mm x 280mm |

| Weight | 0.35 kg |

| Interface/Bus | Modicon Quantum Backplane |

| Compliance | CE, UL, RoHS |

| Supported Protocols | Modbus (via Rack) |

| Typical Power Draw | 400 mA @ 5V |

Harnessing the Schneider Electric 140ACO13000 forges a bulwark of actuation assurance, where its ±0.2% full-scale accuracy endures thermal swings to mirror setpoint intents without the 0.3% creep that hampers rivals—pivotal for valve stroking in batch reactors, where a 0.2mA variance equates to 5% overfill and rework cascades. This steadfastness begets loop longevity: channels maintain settling under varying loop resistances, stabilizing PID responses in fan arrays to trim energy by 1-2% via tighter control bands.

Deeper dividends accrue in diagnostic depth; fault registers per output enable granular scripting—say, derating a channel on short detect to safeguard pumps—curtailing outages from 30 minutes to managed minutes in multi-drop nets. Engineering frugality follows: multirange obviates dedicated modules per span, halving slot counts in dense racks and easing cabling audits for SIL pathways, while 500V isolation streamlines EMC compliance without extra barriers. Throughput the tenure, it lightens service scales—self-latching protections reset 95% of transients autonomously, pushing MTBF beyond 180,000 hours so squads pivot from patchworks to prognostics, where crisp outputs underpin simulation twins for offline honing. For the Schneider Electric 140ACO13000, the alchemy is actuation amplified: it transmutes code into command, yielding processes that propel with poise, unburdened by output’s old uncertainties.

The Schneider Electric 140ACO13000 ingrains itself in theaters where modulated might matters most, like in steel rolling mills, where it pilots hydraulic screws via 0-25mA ramps, its linearity locking gauge tolerances amid inductive clamor for throughput spikes sans strip tears, fortifying process control environments with 99.98% loop fidelity during coil changes. Textile dyeing vats summon it for colorant dosing, scaling 4-20mA to pH actuators in steamy enclosures—update rates hold recipes steady against fabric variances, ensuring shade consistency that sidesteps dye waste in high-volume runs.

Wind turbine nacelles embed it for pitch control, driving servos through remote drops with 30V sink tolerance against gusty EMI, where fault isolation prevents yaw faults that idle blades for days. These embeddings evince its reach: from forge-hot forges to fiber-wet looms, the Schneider Electric 140ACO13000 steels industrial automation’s effector edge, where output’s oath is operational ascendancy.

140ACO02000 – 4-channel voltage/current variant for mixed-signal actuator suites

140ACI04000 – Current input counterpart for balanced closed-loop pairings

140AOM03000 – High-density 16O module for ultra-compact output farms

140AMM09000 – Analog mixed I/O hybrid for bidirectional small-footprint needs

140OAC03000 – AC output alternative for legacy heater or clutch drives

140AOD03000 – Differential output upgrade for long-run noise rejection

ASMBP20 – Fiber MBM linker for remote output clusters in Quantum webs

Before seating the Schneider Electric 140ACO13000 in your Quantum drop, probe the backplane slots for bent pins—a loupe inspection and gentle realign with tweezers averts contact resistance that bloats drops by 0.1mA. Span selection is register-rigorous: post-insert, script the config words in Unity for your ranges (e.g., 0-16000 for 4-20mA), and dry-run a 100Ω load per channel to confirm no inverted flows. Bus loading merits a tally—cap drops at 7A aggregate, as overloads dip rails below 4.8V, muting ramps; Schneider’s profiler tool quantifies this pre-populate. Afford 25mm lateral breathing room, as vertical heat from power bays could crest 60°C in sealed panels.

Nurturing its nuance demands discerning diligence, not drudgery. Bimonthly, interrogate the fault word via Modbus for active bits—overloads mimic shorts, so shunt a 500Ω test resistor to differentiate and log baselines. Quarterly, continuity-check D-subs with a milliohmmeter for <0.2Ω, and in damp domains, apply vapor-corrosion inhibitor to terminals post-wipe to stall oxidation trails. Annually, execute a sweep calibration: source digital ramps and measure settling with a scope across 20mA spans, chasing <3.2ms and ±4µA linearity; docket excursions for predictive swaps. In oscillatory locales, half-yearly clamp audits at 0.6Nm thwart vibration-walks, but cycle the rack post-tighten to flush transients. These observances, etched from fault forensics, interdict 82% of output oddities, consecrating the Schneider Electric 140ACO13000 as your analog apostle.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626