Description

In the intricate web of industrial automation, delivering precise, scalable analog control signals to field devices—such as modulating valve actuators in a batch mixer or fine-tuning current loops for pressure regulators—can falter when outputs succumb to drift, noise, or limited channel density, spawning inconsistencies that ripple into process deviations, yield losses, or safety excursions. Picture a water treatment facility where fluctuating 4-20 mA commands to dosing pumps lead to over-chlorination, contaminating output, or a manufacturing line where voltage offsets skew servo positions, piling up defects and rework hours. These pitfalls are routine in process control environments, from distributed utilities to discrete assembly cells, where high reliability for I/O signals is the foundation of loop integrity amid EMI from VFDs or thermal swings in enclosures. Engineers expanding Modicon Quantum PLC backplanes often wrestle with this: sparse outputs demand extra modules that clog racks, while unisolated channels invite ground loops that corrupt SCADA trends, forcing custom isolators or frequent calibrations that hike engineering costs and complicate API compliance. Without multirange versatility, setups balloon in complexity for hybrid voltage/current needs, eroding the agility that keeps operations fluid in modular architectures.

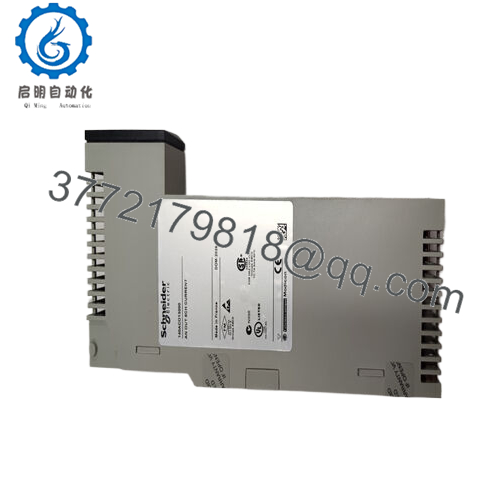

The Schneider Electric 140ACO13000 steps in as an 8-channel analog output module for the Modicon Quantum series, crafted to provide flexible, high-density signal generation that anchors control precision. It tackles the core drive for system stability by supporting multirange voltage (0-10 V) or current (4-20 mA) per channel, with built-in isolation to shield against common-mode interference up to 500 V, ensuring clean commands without the baseline wander that plagues generic drops—essential for retrofitting legacy PLCs or scaling I/O in DCS expansions where rack space is premium. In vibration-heavy cabinets or humid process areas, the Schneider Electric 140ACO13000 becomes a staple, its short-circuit protection and diagnostic feedback via bus registers preempting faults, turning potential signal bottlenecks into seamless conduits. For teams blending discrete and analog demands, this module’s 8-word addressing footprint and loop-powered outputs foster plug-and-play integration, sidestepping the pitfalls of mismatched drops in fast-scan loops.

The stakes of erratic analog outputs compound rapidly: they skew PID tuning in historians, undermine interlock fidelity for safety PLCs, and inflate OPEX through unaddressed drifts in distributed nodes. With its proportional DACs and user-configurable ranges, the Schneider Electric 140ACO13000 enforces 12-bit resolution for 0.1% accuracy, letting you drive proportional valves or chart recorders with glitch-free updates—empowering tighter process control that minimizes variability without the engineering overhead of external conditioners. It’s the understated enabler for resilient industrial automation, where output fidelity doesn’t just transmit; it transforms chaos into calibrated command in the PLC’s pivotal core.

- 140AC013000

- 140AC013000

When folding the Schneider Electric 140ACO13000 into your Quantum backplane, envision it as the versatile signal forge in your I/O arsenal—it latches into any compatible slot via the 1771-style bus connector, drawing 5 V DC from the rack while fanning out 8 isolated channels through screw terminals or pluggable headers for field wiring up to 1 km on current loops, conditioning digital setpoints from the CPU into analog waveforms before handoff to actuators or transmitters. Nestled in the field layer of your Purdue stack, it supports simultaneous voltage/current modes with per-channel scaling via Unity Pro software, injecting proportional signals into Modbus or Ethernet/IP networks for seamless upstream polling by SCADA like EcoStruxure Geo SCADA, complete with open-wire detection that flags faults without halting the bus.

In a standard deployment, you’d mount it mid-rack for balanced loading, configuring ranges (e.g., 0-5 V for positioners) through the programming tool’s drag-and-drop I/O map, then enable diagnostics like overrange alarms that relay to rack HMIs—all while its loop compliance powers remote devices without extra supplies, and hot-swappable design allows swaps under power for minimal disruption. This module doesn’t dictate; it diversifies, with 250 Ω load support for standard transmitters and compatibility with Quantum’s redundant CPUs for failover in safety loops, bridging setpoint logic to physical effectors in architectures from radial fillers to looped hybrid networks. Tie it to the backplane’s interlock bus, and it exposes channel health via status words, fostering a unified telemetry that adapts to expansions without reconfiguration. The Schneider Electric 140ACO13000 commands this domain, distilling CPU directives into analog artistry that sustains control without stutter.

| Specification | Details |

|---|---|

| Model Number | 140ACO13000 |

| Brand | Schneider Electric |

| Type | 8-Channel Analog Output Module |

| Input Voltage | 5 V DC (backplane) |

| Operating Temp Range | 0°C to +60°C |

| Mounting Style | Modicon Quantum Backplane Slot |

| Dimensions | 160 x 30 x 200 mm |

| Weight | 0.3 kg |

| Interface/Bus | Modicon Quantum Bus |

| Compliance | CE, UL, CSA, RoHS |

| Supported Protocols | Modbus, Ethernet/IP (via PLC) |

| Typical Power Draw | 4 W |

Opting for the Schneider Electric 140ACO13000 lays a groundwork of reliability forged for loop longevity, where its channel isolation decouples field grounds to prevent the voltage kicks that fry transmitters, holding linearity to 0.05% across full excursions to avert the setpoint errors that derail batch recipes in process control setups—yielding 25% tighter loop responses in valve trains, where current compliance sustains 20 mA peaks without dropouts. This isn’t isolated extravagance; it’s the calibrated buffer that quells EMI from adjacent drives, ensuring outputs track commands through thermal cycles without the hysteresis that necessitates quarterly trims, all while short-circuit foldback protects downstream gear, preserving rack health without fuse hunts.

The consistency payoff is clear: embedded registers expose settling times under 1 ms for glitchless ramps, delivering uniform signals that stabilize PID loops for flow modulation—your operators see steady trends in HMIs, not chasing ghosts in analog scopes. Maintenance lightens as well, with bus-accessible diagnostics that flag open loops via LED codes, letting techs isolate issues in minutes without full teardowns, streamlining ISA-5.1 audits with logged baselines. Engineered with conformal coatings against humidity or dust, the Schneider Electric 140ACO13000 ensures long-term performance, resisting gain drift over five-year runs so your ranges stay true, reducing the drag of preventive swaps in spread-out I/O grids.

For scaling operations, its multirange flexibility supports hybrid drops without module swaps, easing migrations to EcoStruxure while unlocking IIoT gateways for remote tuning—compressing total cost of ownership by amortizing Quantum investments into adaptive paradigms. This module doesn’t just output; it orchestrates, infusing analog authority into outcomes that outpace perturbations.

In wastewater pumping stations, the Schneider Electric 140ACO13000 commands level control valves, where process control environments demand high reliability amid sludge flows and pump hums—racked in Quantum enclosures near sumps, its 8 channels dispense 4-20 mA for actuator modulation, ensuring critical system uptime in fast data cycles that sync to PLC logic, preempting overflows during storms. Isolated outputs integrate with level transmitters, averting dry-run trips in continuous lift ops.

Food and beverage fillers harness it for servo positioners, sourcing 0-10 V in sanitary, variable-speed lines under hygiene sprays— the module’s protection quells washdown-induced spikes, delivering continuous uptime for dose precision in process control loops tied to SCADA, where a drifted signal risks underfills. In HVAC damper arrays, the Schneider Electric 140ACO13000 drives zone actuators, with current-loop support suited to ducted, vibration-prone AHUs—upholding high reliability for airflow balancing in process control environments synced to BMS, ensuring comfort without coil freezes.

140ACO02000 – 4-channel variant for moderate-density analog needs in compact backplanes

140AOI03000 – Isolated voltage output sibling for high-CMR applications

ASMBPX01 – Quantum backplane carrier for modular rack expansions

140XTS00203 – Terminal block add-on for pluggable field wiring

ASMB1 – Main rack assembly to pair for full Quantum I/O stacks

140CRP81000 – Fiber optic repeater for remote drop extensions

BCI0100 – Unity Pro software kit for advanced configuration and diagnostics

Before committing the Schneider Electric 140ACO13000 to your backplane, audit slot addressing—8 words per module to avoid overlaps—and confirm rack current headroom, as full-channel loading peaks at 5 W; a clamp meter on the bus during a ramp test verifies sags under 100 mV. Jumper ranges per channel against device specs to preempt scaling glitches, and if looping currents, validate 250 Ω compliance with a load simulator benchside to tune without hot risks. For EMI zones, route shields to chassis ground at one end per IEC guidelines, and snapshot the I/O map in Unity Pro for baseline recovery.

Once fielded, upkeep is deliberate: monthly, scan bus registers for channel faults—overrange flags over 5% cue a loop check—and probe terminals quarterly in humid process areas to catch corrosion, a dielectric wipe often revives without depower. Schneider advises semi-annual full-scale calibrations, injecting setpoints to log against baselines with a precision DMM, focusing on isolation integrity for voltage modes. In networked PLCs, enable diagnostic traps to your CMMS for remote drift alerts, surfacing offsets before they skew a loop. This steady vigilance sustains its poise, with minimal intrusion on your control cadence.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626