Description

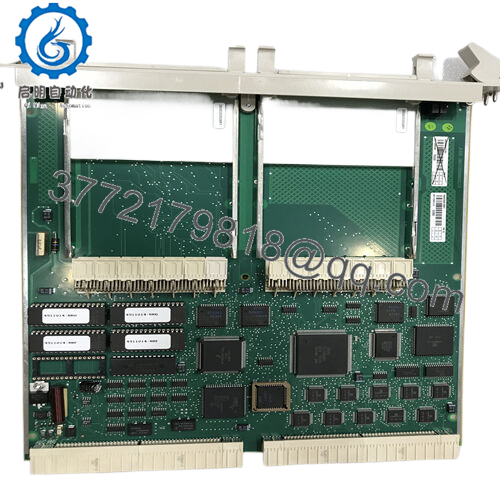

| Model | SC560 |

| Brand | ABB |

| Type | Safety Controller |

| Safety Integrity Level | SIL 3 (per IEC 61508) |

| Processing Architecture | Dual-core redundant processors |

| I/O Capacity | Up to 512 safety-rated I/O points |

| Communication Protocols | Safety over Ethernet, Profibus PA-SIL, Modbus Safety |

| Power Supply | 24 V DC ± 10% (redundant configuration required) |

| Operating Temperature | -40°C to 70°C (-40°F to 158°F) |

| Mounting | DIN rail or panel mounting |

| Dimensions | 180 mm x 250 mm x 130 mm (W x H x D) |

| Weight | 2.8 kg |

| Diagnostic Coverage | ≥99% for dangerous failures |

| Certifications | IEC 61508, IEC 61511, ATEX, UL 1998, TÜV SÜD |

| Response Time | ≤100 ms for safety functions |

| Environmental Rating | IP20 |

SC560

The SC560 is a high-performance safety controller designed specifically for safety instrumented systems requiring SIL 3 capability, providing the core logic processing for critical safety functions.

SC560

As the central decision-making component in safety loops, this controller continuously evaluates inputs from safety sensors, validates their integrity, and executes pre-programmed safety actions when hazardous conditions are detected. Its design focuses on delivering maximum fault tolerance through redundant architectures and comprehensive self-diagnostics, making it ideal for mission-critical applications in industries governed by strict safety regulations. What distinguishes the SC560 is its combination of powerful processing capabilities, modular design, and compliance with global safety standards, offering system integrators a flexible solution that simplifies safety system design while ensuring regulatory compliance.

Main features and advantages:

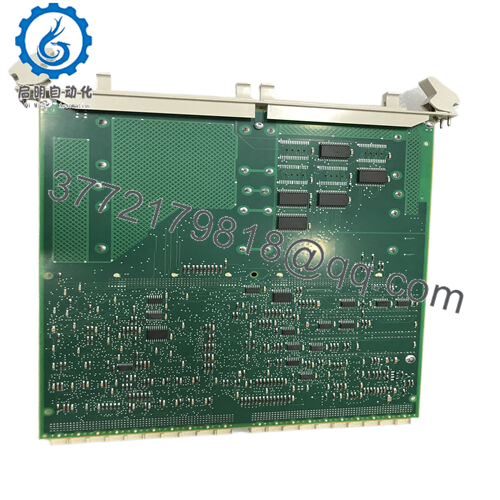

A key strength of the SC560 is its redundant hardware architecture, featuring dual processors that operate in a hot-standby configuration to eliminate single points of failure. The controller employs diverse processing paths and continuous cross-checking to detect internal faults, ensuring dangerous failures are identified and addressed before they can compromise safety functions. With support for multiple safety communication protocols including Safety over Ethernet and Profibus PA-SIL, the SC560 seamlessly integrates with safety sensors, actuators, and other safety devices. Hardware-wise, the SC560 features a rugged metal chassis with conformal coating on circuit boards, ensuring reliable operation in harsh industrial environments with temperatures ranging from -40°C to 70°C. Its modular design supports easy expansion of I/O capabilities, while intuitive status indicators provide instant visual feedback on system health and safety loop status.

Application areas:

In safety-critical industrial operations such as chemical processing, oil and gas production, and power generation, the ability to detect hazardous conditions and initiate protective actions is paramount to preventing catastrophic incidents. These high-risk environments require specialized safety controllers that can continuously monitor process variables, validate safety interlocks, and execute emergency shutdown sequences with absolute reliability. Whether protecting against overpressure in a reactor vessel, preventing equipment overspeed in a turbine system, or ensuring proper isolation in a hazardous material handling process, engineers depend on safety controllers that meet the most stringent functional safety standards. This is where the SC560 excels, serving as a SIL 3-certified safety controller in industrial automation setups where failure to act could result in personnel injury, environmental damage, or production losses. Used in safety instrumented systems (SIS) worldwide, the SC560 addresses key challenges such as fault tolerance, diagnostic coverage, and seamless integration with safety sensors and actuators.

Related products:

ABB SB822 – Safety signal conditioning module that provides processed sensor data to the SC560.

ABB SD831 3BSE036207R1 – Safety relay module that executes shutdown actions under SC560 control.

ABB SAFT112POW – Redundant power supply unit that provides secure power to the SC560 system.

ABB SAFT181INF – Safety-certified interface module that enables communication between the SC560 and supervisory systems.

ABB RXTUG – Terminal unit that provides secure wiring connections for the SC560’s I/O signals.

ABB CI854A 3BSE036411R1 – Safety-rated communication module that connects the SC560 to Profibus networks.

ABB TU847 3BSE008511R1 – Safety terminal unit that houses I/O modules connected to the SC560.

ABB PM866K01 3BSE022496R1 – Standard controller that receives safety status information from the SC560.

Installation and maintenance:

Before installing the SC560, ensure the mounting location provides protection from extreme temperatures, vibration, and electromagnetic interference. Verify that the installation complies with safety distance requirements between safety and non-safety circuits as specified in IEC 61508. The SC560 must be connected to a fully redundant 24V DC power supply with separate feed paths and overcurrent protection for each power input. Maintain a minimum clearance of 100 mm around the controller to facilitate airflow and simplify access for wiring and maintenance. Use shielded, twisted-pair cables for all safety communications and I/O connections, with shields grounded at both ends using dedicated safety grounding points isolated from standard system grounds.

For optimal maintenance of the SC560, implement a comprehensive testing program that includes monthly diagnostic checks using ABB’s safety engineering software to verify system integrity and diagnostic coverage. Perform quarterly visual inspections to check for loose connections, signs of corrosion, or physical damage. Conduct proof tests according to the safety requirement specification, typically every 1-3 years depending on the application’s safety integrity requirements and operating environment. During maintenance, never bypass safety functions or disable diagnostic circuits. When making configuration changes, implement a formal change management process and perform full function testing before returning the system to service. Ensure all maintenance personnel are certified in safety instrumented system procedures and familiar with the SC560’s specific requirements.

Other ABB product models:

ABB 3BHE044249R0003

ABB 3BHE046836R0101

ABB 3BHE046836R0102 GFD563A102

ABB 3BHL000250P0002

ABB 3BHL000391P0101 5SHX1445H0001

ABB 3BHL000406P0009

ABB 3BHL000406P0103

ABB 3BHL000519P0001

ABB 3BHL000734P0003

ABB 3BHL000986P0006

ABB 3BHL001433P0001

ABB 3BHT300011R1

ABB 3BSE003816R1 SC520

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004172R1 PFTL101A-2KN

ABB 3BSE004172R1 PFTL101A 2KN

ABB 3BSE018135R1

ABB 3BSE019050R200 PFTL301E-0.2kN

ABB 3BSE030928R1 SM810K01

ABB 3BSE042235R2

ABB 3BSE042236R1 PP865

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE043660R1 CI867K01

ABB 3BSE056899R1 CI873K01

ABB 3BSE066490R1

ABB 3BSE076939R1 PM866AK01

ABB 3BSE091722R1 LD 810HSE EX

ABB 3BSE092689R1

ABB 3BSE092689R1 CI867AK01

ABB 3BSE092978R1 PP881

ABB 3BUS208797-001

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626