Description

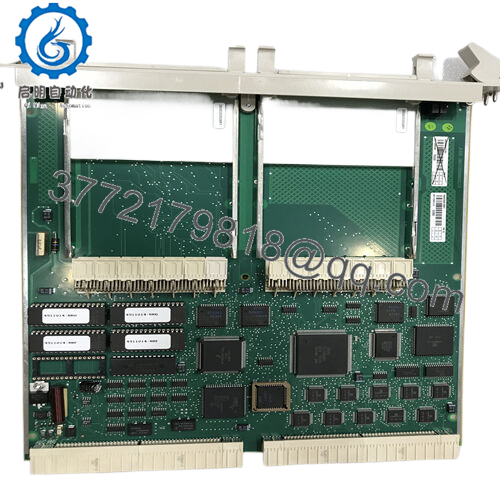

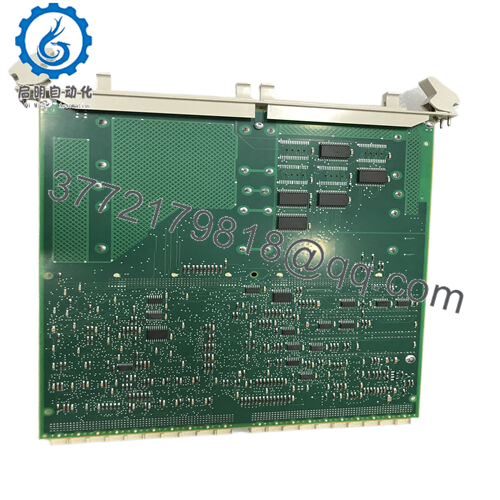

Product Model: SC560

Product Brand: ABB

Product Series: SC560 Submodule / Monitoring Module

Product Features:

- Submodule carrier with integrated local CPU for distributed control systems

- Supports signal acquisition, processing, and communication in real time

- Rugged industrial design with compact footprint (486 × 288 × 27 mm, ~0.76 kg)

- Designed for 24 V DC systems, supports modular I/O expansion and protocol interfacing

- SC560

- SC560

Product Role & System Fit

In a distributed control system (DCS) or advanced automation architecture, the SC560 acts as a submodule carrier / local intelligence node within I/O racks or control shelves. Its job is more than passive forwarding — it houses a local CPU, handles real-time signal processing, communicates with higher levels, and supports modular I/O expansion. The module is part of ABB’s SC560 family and is commonly identified via part number 3BSE008105R1

As automation systems push closer to the “edge,” having modules like SC560 integrated into the field rack allows more pre-processing of sensor data, local alarming, and resilience in communication loss scenarios. The SC560 fits between I/O modules and central controllers: it aggregates I/O, runs lightweight logic or filtering, and passes data upstream via standard protocols.

Because it includes a local CPU, the SC560 can offload routine computations (scaling, diagnostics, filtering) from the main controller. It also supports modular expansion — additional I/O boards or signal modules can plug into it, making it scalable. Its mechanical dimensions and electrical interface are designed to match ABB control racks or submodule frameworks, making it suitable for retrofits or new builds alike.

In retrofit or upgrade projects, the SC560 often replaces older I/O carrier or dumb backplane modules. Because it retains physical compatibility (rack cutouts, connector spacing) and adds CPU capabilities, many engineers find it convenient to upgrade legacy racks to intelligent nodes with minimal rewiring.

Applications & Industry Context

In heavy industries — power generation, oil & gas, chemical, pulp and paper — thousands of sensors and actuators must be monitored and controlled. The SC560 becomes the modular brain in that network: it handles channel multiplexing, early diagnostics, and local decision logic. In a fossil or nuclear power plant, for example, a rack outfitted with SC560 may host dozens of temperature, pressure, flow, and valve I/O lines. The SC560’s local CPU can filter, alarm, or average signals before sending them to the supervisory DCS.

In large petrochemical complexes, environmental, safety, and performance loops often need fast local feedback. SC560 modules, distributed across clarifiers, reactors, or compressor skids, allow local logic to run independent buffering or safety interlocks, while central systems manage overall control.

Another typical use is in modular process skids—where a containerized unit has its own batch control, instrumentation, and communication lines. The SC560 can serve as the local controller or aggregator, driving actuators and sending summarized data upstream.

Field engineers often report that the switch from dumb carriers to intelligent carriers like SC560 reduces fault propagation: a wiring short or failing analog input in one node no longer crashes the entire system; the SC560 can isolate and continue operating other channels.

Because SC560 supports real-time data capture and local diagnostics, it helps improve system availability. For example, when an I/O module begins to drift, SC560 can flag the channel or preemptively mark it for replacement — reducing unplanned downtime.

Technical Features & Benefits

The SC560 (3BSE008105R1) brings together several engineered features that appeal to seasoned automation professionals:

- Integrated local CPU: The SC560 carries a built-in processor capable of handling local tasks (scaling, diagnostics, logic) without relying entirely on central controllers

- High-density I/O capacity: Though its exact I/O count depends on submodule expansions, the carrier is designed for dense configurations, supporting many channels in a slim profile. Its dimensions (~486 × 288 × 27 mm) and weight (~0.76 kg) reflect that balance of density and compactness

- Standard 24 V DC supply interface: The SC560 module is designed for 24 V DC operational environments, common in industrial control racks. It supports internal bus powering of submodules and upstream communication lines

- Rugged industrial design: Built for industrial environments, SC560 tolerates typical temperature ranges (–20 °C to +60 °C is a reference from Chinese distributor specs) and meets IP20 protections in cabinet environments

- Local diagnostics and health monitoring: The SC560 can monitor channel integrity, input range anomalies, and internal errors, then report them upstream to central monitoring or local HMI panels.

- Modular scalability and flexibility: Because SC560 is a carrier node, additional submodules (analog, digital, specialty I/O) can be attached or replaced over time. This modularity ensures system growth without major architectural redesign.

- Protocol flexibility: While many listings do not specify all protocols, SC560 is designed to interface with ABB’s DCS or control systems and to support distributed control communication stacks. Some modules in the same family support fieldbus or Ethernet transport.

- Compact footprint: With its slim profile (27 mm thickness) and moderate weight, the SC560 suits standard control racks without excessive space consumption

These features allow SC560 to serve as a dependable local node in modern automation architectures, combining I/O aggregation, local logic, and robust monitoring.

Technical Specifications

Here is a condensed specification overview based on available sources:

| Parameter | Description / Typical Value |

|---|---|

| Model / Part | SC560 (3BSE008105R1) |

| Type | Submodule Carrier / Monitoring & Communication Module |

| Local CPU | Integrated local processing (for signal handling & diagnostics) |

| Dimensions | 486 × 288 × 27 mm |

| Weight | ~0.76 kg |

| Power Supply | 24 V DC input |

| Ambient Operating Temp | –20 °C to +60 °C (distributor spec) |

| Protection / Enclosure | IP20 (cabinet use) |

| I/O Expansion Support | Supports connection of submodules (analog, digital, specialty) |

| Communication Interfaces | Interface to higher-level controller / bus (various protocols) |

| Certifications / Standards | ABB standard module design |

| Catalog / Origin | Sweden / ABB module series |

Related Models

Here are a handful of modules and carriers in the ABB / SC560 ecosystem or similar functions:

- SC560-3BSE004055R1 — variant with different measurement / communications range

- SC560-3BSE002025R1 — alternate SC560 for smaller-scale use

- SC561 / SC562 — possible adjacent modules in the SC500 family (for extended features)

- Advant OCS I/O Carriers — older ABB I/O carrier modules in the Advant / DCS family

- AC 800M / AC 800F I/O Rack Carriers — ABB’s larger control system carriers with CPU / board integration

- DCS I/O modules (e.g. Bailey, Emerson, Honeywell equivalents) — non-ABB modules that perform similar I/O aggregation roles

Each of these modules differs in CPU capability, supported I/O count, communication options or mechanical form factor.

Installation & Maintenance Insights

From hands-on field experience, successful implementation of SC560 requires attention to a few practical details:

- Rack alignment and secure mounting

The SC560 must align precisely with backplane connectors and ensure solid mechanical contact. Vibration or rack flex can lead to intermittent faults, so mount racks on stable frames with proper supports. - Power supply stability

Since SC560 expects 24 V DC supply, ensure that upstream regulators, distribution lines, and redundancy (if used) supply clean, stable power. Voltage droop or noise can affect internal CPU and I/O module performance. - Wiring discipline

Proper shielding, grounding, and cable segregation help reduce interference—especially near power lines or heavy motors. SC560’s internal CPU may pick up noise if wiring isn’t disciplined. - Commissioning and diagnostics

After installation, run a diagnostic check of all I/O channels, observe LED or fault indicators, and validate communication to the central controller. Use the module’s local CPU to test signal responses and fault reporting. - Firmware / configuration tracking

Maintain version control of configuration and firmware (if applicable). When replacing or upgrading SC560 modules, ensure compatible firmware to avoid mismatches or communication failures. - Hot swap / replacement planning

If the system design allows it, practice swapping SC560 modules in a test environment to verify that neighboring nodes and controllers handle the replacement cleanly. Proper backup of configuration is essential. - Periodic inspection

Inspect for dust accumulation, connector corrosion, or heating signs. I/O card slot connectors should be cleaned and reseated if necessary. Most faults in control racks arise from connection deterioration rather than CPU or module logic.

One field anecdote: in a pulp mill control room, an SC560 module had intermittent faults due to a slightly loose carrier connector. Reseating the module cured repeated faults overnight. Until then, engineers had chased phantom I/O errors in instrument loops. That underscores the importance of solid mechanical seating in addition to logic configuration.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626