Description

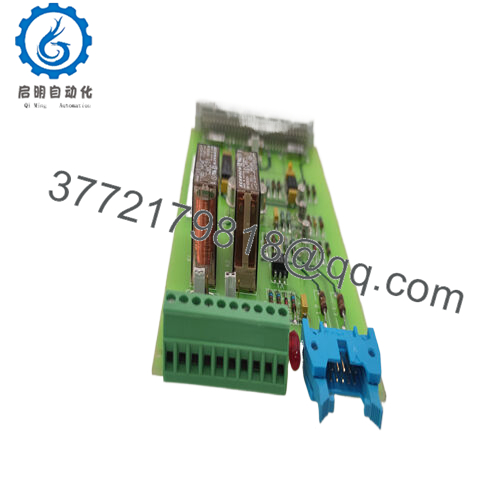

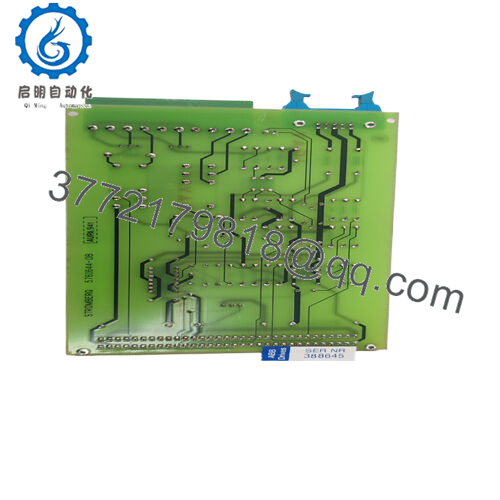

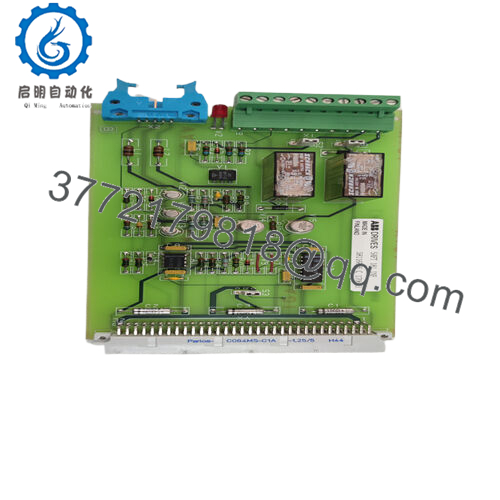

| Model | SAFT181INF |

| Brand | ABB |

| Type | Industrial Interface/Communication Module |

| Supported Protocols | Modbus RTU, Profibus DP, Ethernet/IP |

| Communication Ports | 2 x Ethernet (10/100 Mbps), 1 x RS485, 1 x Profibus DP |

| Power Supply | 24 V DC ± 10% |

| Isolation | 2.5kV galvanic isolation (signal to power) |

| Operating Temperature | -40°C to 70°C (-40°F to 158°F) |

| Mounting | DIN rail mounting (35 mm) |

| Dimensions | 110 mm x 160 mm x 100 mm (W x H x D) |

| Weight | 580 grams |

| Protection Features | Overvoltage protection, ESD protection |

| Certifications | IEC 61010, UL 508, CSA C22.2, ATEX |

| Cooling | Natural convection |

| Environmental Rating | IP20 (front panel) |

SAFT181INF

The SAFT181INF is an advanced industrial interface module designed specifically for ABB’s Symphony Plus and AC 800M control systems, providing reliable connectivity between different system components and external devices. As a critical communication hub in control system architecture, this module enables data exchange between controllers, I/O modules, and third-party equipment through multiple industrial protocols.

SAFT181INF

Its design focuses on delivering secure, high-speed communication with robust noise immunity, making it ideal for mission-critical applications in power generation, oil and gas, and chemical processing industries. What distinguishes the SAFT181INF is its combination of multi-protocol support and rugged construction, offering system integrators a flexible solution that connects diverse system elements while ensuring reliable operation in harsh industrial environments.

SAFT181INF

Main features and advantages:

A key strength of the SAFT181INF is its versatile protocol support, including Modbus RTU, Profibus DP, and Ethernet/IP, enabling seamless integration with both legacy and modern industrial equipment. This flexibility eliminates the need for multiple specialized interface modules, simplifying system architecture and reducing maintenance complexity. The module incorporates advanced signal isolation technology (2.5kV galvanic isolation) between communication ports and power supply, protecting sensitive control system components from electrical noise and ground loops common in industrial environments. Hardware-wise, the SAFT181INF features a rugged metal housing with excellent electromagnetic compatibility (EMC) performance, ensuring reliable operation in temperatures ranging from -40°C to 70°C. Its compact design supports easy installation in standard control cabinets, while status indicator LEDs provide instant visual feedback on communication status and operational health.

SAFT181INF

Application areas:

In modern industrial automation systems, seamless communication between diverse control components is essential for achieving optimal process visibility and operational efficiency. Power plants, manufacturing facilities, and chemical processing plants rely on robust interface modules to bridge different system segments, enabling data exchange between controllers, I/O modules, and external devices. Whether integrating legacy equipment with modern control systems, facilitating data transfer between safety and standard control networks, or enabling remote monitoring capabilities, engineers need reliable connectivity solutions that can handle industrial noise and harsh environmental conditions. This is where the SAFT181INF excels, serving as a high-performance interface module in industrial automation setups where secure and efficient data transmission directly impacts system functionality and decision-making. Used in industrial automation applications ranging from distributed control systems (DCS) to machine-to-machine communication networks, the SAFT181INF addresses key challenges such as protocol conversion, signal isolation, and seamless integration with ABB’s automation platforms.

Related products:

ABB SAFT112POW – Power supply unit that provides stable 24V DC power to the SAFT181INF for reliable operation.

ABB SA811F – Advanced communication module that forms redundant network connections with the SAFT181INF.

ABB PM866K01 3BSE022496R1 – Processor module that exchanges data with external systems via the SAFT181INF.

ABB RXIIK 4 – Analog input module whose measurement data is transmitted to supervisory systems through the SAFT181INF.

ABB SA9923A-E – Analog output module that receives control signals routed through the SAFT181INF.

ABB CI854A 3BSE036411R1 – Profibus module that connects to the SAFT181INF for extended network coverage.

ABB RXTUG – Terminal unit that provides secure wiring connections for the SAFT181INF’s communication ports.

ABB SD831 3BSE036207R1 – Safety controller that communicates safety status information via the SAFT181INF.

Installation and maintenance:

Before installing the SAFT181INF, ensure the mounting location provides protection from direct exposure to moisture, corrosive gases, and excessive vibration. Verify that the network infrastructure is properly configured to support the module’s communication protocols and bandwidth requirements. The module should be connected to a dedicated 24V DC power supply, preferably from a redundant source like the SAFT112POW, with appropriate overcurrent protection. Maintain a minimum clearance of 30 mm around the module to facilitate airflow and simplify cable management. When routing communication cables, separate signal wiring from high-voltage power cables to minimize electromagnetic interference, using shielded cables with properly grounded shields for all connections.

For optimal maintenance of the SAFT181INF, implement a monthly inspection schedule to verify communication status using the module’s status indicators and network diagnostic tools. Perform quarterly checks of all cable connections to ensure they remain secure and free from corrosion. Monitor network traffic periodically to identify potential bottlenecks or communication errors that could affect system performance. Firmware updates should be applied during scheduled maintenance windows when available through ABB’s support portal, ensuring compatibility with system upgrades and security patches. In case of communication faults, use the module’s built-in diagnostic features to isolate issues, checking both physical connections and protocol configurations before replacing components.

Other ABB product models:

ABB 3BHE044249R0003

ABB 3BHE046836R0101

ABB 3BHE046836R0102 GFD563A102

ABB 3BHL000250P0002

ABB 3BHL000391P0101 5SHX1445H0001

ABB 3BHL000406P0009

ABB 3BHL000406P0103

ABB 3BHL000519P0001

ABB 3BHL000734P0003

ABB 3BHL000986P0006

ABB 3BHL001433P0001

ABB 3BHT300011R1

ABB 3BSE003816R1 SC520

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004172R1 PFTL101A-2KN

ABB 3BSE004172R1 PFTL101A 2KN

ABB 3BSE018135R1

ABB 3BSE019050R200 PFTL301E-0.2kN

ABB 3BSE030928R1 SM810K01

ABB 3BSE042235R2

ABB 3BSE042236R1 PP865

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE043660R1 CI867K01

ABB 3BSE056899R1 CI873K01

ABB 3BSE066490R1

ABB 3BSE076939R1 PM866AK01

ABB 3BSE091722R1 LD 810HSE EX

ABB 3BSE092689R1

ABB 3BSE092689R1 CI867AK01

ABB 3BSE092978R1 PP881

ABB 3BUS208797-001

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626