Description

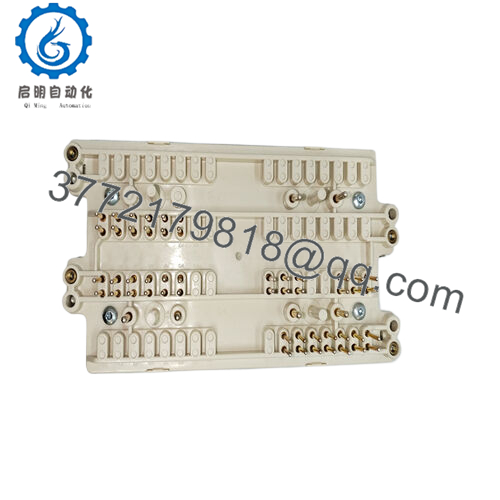

| Model | RXIIK 4 |

| Brand | ABB |

| Type | Multi-channel Analog Input Module |

| Power Supply | 24 V DC ± 10% |

| Operating Temperature | -40°C to 70°C (-40°F to 158°F) |

| Mounting | DIN rail mounting (35 mm) |

| Dimensions | 120 mm x 160 mm x 220 mm (W x H x D) |

| Weight | 650 grams |

| Interfaces | 16 analog input channels, 1 x backplane connector |

| Certifications | IEC 61010, ATEX, IECEx, UL 508, CSA C22.2 |

| Cooling | Natural convection with integrated heat sink |

| Environmental Rating | IP20 (front panel), NEMA 1 |

RXIIK 4

The RXIIK 4 is a versatile analog input module designed specifically for integration with ABB’s AC 800M distributed control system, a leading platform in heavy process industries requiring precise parameter monitoring. As a critical component in the control system architecture, this module functions as the primary interface between analog field devices and the central processing unit, converting physical measurements into digital data that the control system can analyze and act upon.

RXIIK 4

Its design focuses on handling multiple sensor types without sacrificing accuracy, making it ideal for complex industrial environments where diverse process variables need simultaneous monitoring. What distinguishes the RXIIK 4 is its combination of high channel density and advanced signal processing capabilities, providing system integrators with a flexible solution that reduces cabinet space requirements while maintaining measurement integrity.

Main features and advantages:

A key advantage of the RXIIK 4 is its expanded channel capacity, featuring 16 analog input channels that can each be individually configured for different signal types. This includes support for thermocouples, RTDs, 4-20mA current signals, and 0-10V voltage inputs, eliminating the need for multiple specialized modules in mixed-signal applications. The module incorporates advanced digital filtering technology that dynamically adjusts to signal conditions, minimizing the impact of electrical noise from nearby motors, drives, and high-voltage equipment common in industrial facilities. Hardware-wise, the RXIIK 4 features a robust construction with industrial-grade components and conformal coating, ensuring reliable operation in temperatures ranging from extreme cold to moderate heat. Its modular design supports easy system expansion, while the hot-swappable capability allows for maintenance or replacement without interrupting critical processes—a crucial feature in continuous-production environments.

Application areas:

In chemical processing plants, wastewater treatment facilities, and industrial manufacturing lines, precise measurement of analog process variables forms the foundation of quality control and operational safety. These environments often present challenging conditions—including high humidity, vibration, and electromagnetic interference—that can compromise signal integrity. Engineers responsible for monitoring critical parameters like pH levels, flow rates, and chemical concentrations need reliable input modules that can deliver accurate data even in these harsh settings. This is where the RXIIK 4 excels, serving as a high-performance interface between field sensors and control systems in industrial automation applications where measurement precision directly impacts process efficiency and regulatory compliance. Used in industrial automation setups ranging from distributed control systems (DCS) to process monitoring networks, the RXIIK 4 addresses key challenges such as multi-signal compatibility, noise reduction, and seamless integration with ABB’s control platforms.

Related products:

ABB RYDDI 2H 1MRK000842-HA – Digital output module that pairs with the RXIIK 4 to provide control signals for valves and actuators based on measured inputs.

ABB CI858 3BSE058459R1 – PROFINET communication module enabling high-speed data transfer between the RXIIK 4 and AC 800M controller.

ABB PM866K01 3BSE022496R1 – High-performance processor module that analyzes data from the RXIIK 4 in complex control applications.

ABB TU847 3BSE008511R1 – Terminal unit designed to provide secure field wiring connections to the RXIIK 4 module.

ABB TB851 3BSE008512R1 – Terminal base that provides mechanical support and electrical connectivity for the RXIIK 4.

ABB SD831 3BSE036207R1 – Safety controller module that integrates with the RXIIK 4 in SIL 3-rated safety instrumented systems.

ABB AI893 3BSE013230R1 – High-accuracy analog input module that complements the RXIIK 4 in applications requiring specialized signal conditioning.

ABB AC800M CM572 3BSE013229R1 – Ethernet communication module facilitating data exchange between the RXIIK 4 and plant-wide networks.

Installation and maintenance:

Before installing the RXIIK 4, verify that the mounting rail is properly secured and grounded to prevent electrical noise interference. Conduct a pre-installation check of the ambient environment, ensuring the module will operate within its specified temperature and humidity ranges. Maintain a minimum clearance of 30 cm from high-voltage cables and motor drives to minimize electromagnetic interference. The backplane connection to the AC 800M system should be inspected for cleanliness and proper alignment before installation, as this interface carries both power and communication signals. Allow at least 50 mm of space around the module for adequate airflow, especially when installing multiple modules in a control cabinet.

For optimal maintenance of the RXIIK 4, implement a regular inspection schedule that includes monthly diagnostic checks using ABB’s Control Builder M software to verify channel accuracy and signal integrity. Perform quarterly visual inspections to check for loose connections, corrosion, or physical damage to terminals and housing. Calibration should be conducted annually using traceable standards to maintain measurement accuracy, with documentation stored in compliance with industry regulations. When replacing or reconfiguring the RXIIK 4, utilize the hot-swap capability following proper shutdown procedures to avoid process interruptions. Always use anti-static equipment when handling the module to protect sensitive electronic components from electrostatic discharge.

Other ABB product models:

ABB 3BHE044249R0003

ABB 3BHE046836R0101

ABB 3BHE046836R0102 GFD563A102

ABB 3BHL000250P0002

ABB 3BHL000391P0101 5SHX1445H0001

ABB 3BHL000406P0009

ABB 3BHL000406P0103

ABB 3BHL000519P0001

ABB 3BHL000734P0003

ABB 3BHL000986P0006

ABB 3BHL001433P0001

ABB 3BHT300011R1

ABB 3BSE003816R1 SC520

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004172R1 PFTL101A-2KN

ABB 3BSE004172R1 PFTL101A 2KN

ABB 3BSE018135R1

ABB 3BSE019050R200 PFTL301E-0.2kN

ABB 3BSE030928R1 SM810K01

ABB 3BSE042235R2

ABB 3BSE042236R1 PP865

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE043660R1 CI867K01

ABB 3BSE056899R1 CI873K01

ABB 3BSE066490R1

ABB 3BSE076939R1 PM866AK01

ABB 3BSE091722R1 LD 810HSE EX

ABB 3BSE092689R1

ABB 3BSE092689R1 CI867AK01

ABB 3BSE092978R1 PP881

ABB 3BUS208797-001

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626