Description

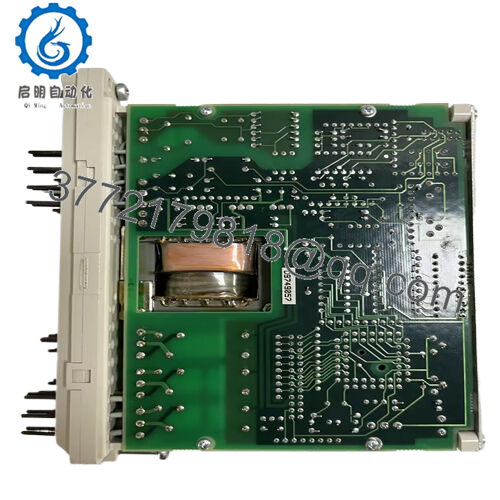

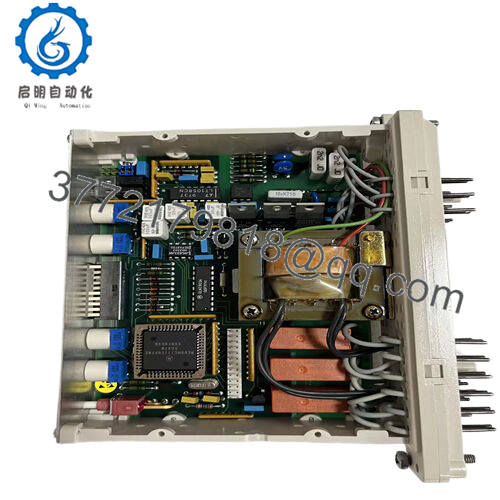

| Model | RXIDK 2H 1MRK000838-HA |

| Brand | ABB |

| Type | Analog Input Module |

| Power Supply | 24 V DC ± 10% |

| Operating Temperature | -40°C to 70°C (-40°F to 158°F) |

| Mounting | DIN rail mounting (35 mm) |

| Dimensions | 100 mm x 160 mm x 220 mm (W x H x D) |

| Weight | 580 grams |

| Interfaces | 8 analog input channels, 1 x backplane connector |

| Certifications | IEC 61010, ATEX, IECEx, UL 508 |

| Cooling | Natural convection with heat sink |

| Environmental Rating | IP20 (front panel), NEMA 1 |

RXIDK 2H 1MRK000838-HA

The RXIDK 2H 1MRK000838-HA is a high-performance analog input module designed for use in ABB’s AC 800M distributed control system, a widely deployed platform in heavy industries requiring precise process control. As a critical component in the control system architecture, this module acts as the bridge between field sensors and the central controller, converting raw analog signals from devices like thermocouples, pressure transmitters, and flow meters into digital data that the system can process.

RXIDK 2H 1MRK000838-HA

Its role is essential in applications where accurate measurement of physical parameters directly impacts product quality, energy efficiency, and safety compliance. What sets the RXIDK 2H 1MRK000838-HA apart is its ability to handle multiple signal types while maintaining high accuracy, making it a valuable asset for process engineers and system integrators working on complex industrial projects.

Main features and advantages:

A key strength of the RXIDK 2H 1MRK000838-HA is its versatile signal handling capability, supporting a wide range of analog input types including thermocouples, RTDs, 4-20mA current loops, and 0-10V voltage signals. This flexibility eliminates the need for multiple specialized modules, simplifying system design and reducing inventory requirements. The module’s advanced signal conditioning technology ensures measurement accuracy even in electrically noisy environments common in industrial facilities, with built-in filtering that minimizes interference from motors, transformers, and other high-power equipment. Hardware-wise, the RXIDK 2H 1MRK000838-HA features a rugged design with conformal coating on circuit boards, providing protection against dust, moisture, and chemical contaminants often present in industrial settings. Its hot-swappable design allows for maintenance without system shutdown, maximizing operational uptime—a critical advantage in continuous-process industries.

Application areas:

In power generation facilities, oil and gas processing plants, and large-scale manufacturing complexes, the seamless flow of data between field devices and control systems is critical for maintaining operational efficiency and safety. These industrial environments present unique challenges—from high electrical noise to extreme temperature variations—demanding robust I/O modules that can reliably transmit critical process data without compromise. Whether monitoring pressure transducers in a chemical reactor, controlling valve actuators in a pipeline, or collecting temperature readings from a turbine, engineers require components that deliver consistent performance in harsh conditions. This is where the RXIDK 2H 1MRK000838-HA excels, serving as a vital interface in industrial automation systems where data integrity and operational continuity are non-negotiable. Used in industrial automation setups ranging from distributed control systems (DCS) to supervisory control and data acquisition (SCADA) networks, the RXIDK 2H 1MRK000838-HA addresses key challenges like signal conditioning, noise immunity, and seamless integration with legacy and modern control platforms.

Related products:

ABB RYDDI 1H 1MRK000840-HA – Digital output module that works with the RXIDK 2H to provide control signals to actuators and valves.

ABB RXDIO 1H 1MRK000839-HA – Digital input module that complements the analog capabilities of the RXIDK 2H for monitoring discrete sensors and switches.

ABB CI854A 3BSE036411R1 – Communication interface module that connects the I/O system to the AC 800M controller via Profibus DP.

ABB PM864K01 3BSE018105R1 – Main processor unit of the AC 800M system that processes data from the RXIDK 2H module.

ABB TU846 3BSE008509R1 – I/O terminal unit that provides physical connection points for field wiring to the RXIDK 2H.

ABB TB850 3BSE008510R1 – Terminal base that provides mechanical support and electrical connection for the RXIDK 2H module.

ABB SD821 3BSE022469R1 – Safety relay module that integrates with the RXIDK 2H in safety-critical applications requiring SIL 2/3 compliance.

ABB AC800M CI853A 3BSE013236R1 – Ethernet/IP communication module enabling data exchange between the RXIDK 2H and Ethernet-based systems.

Installation and maintenance:

When preparing to install the RXIDK 2H 1MRK000838-HA, ensure the mounting rail is properly grounded to minimize electrical noise transfer to the module. The surrounding environment should be checked for potential sources of electromagnetic interference, with a minimum distance of 30 cm maintained from high-voltage cables and motor controllers. Verify that the backplane connection to the AC 800M system is clean and secure, as this interface carries both power and communication signals. Allow at least 50 mm of clearance on all sides of the module to ensure adequate airflow, particularly in enclosures where multiple I/O modules are installed.

For maintenance of the RXIDK 2H 1MRK000838-HA, schedule monthly diagnostic checks using ABB’s Control Builder M software to verify signal accuracy and channel performance. Perform visual inspections quarterly, checking for loose connections, signs of corrosion, or damage to the terminal block. When replacing or reconfiguring the module, use the hot-swap procedure outlined in the manual to avoid process interruptions. Calibration should be performed annually using certified standards to maintain measurement accuracy, with records stored in accordance with industry regulatory requirements. Always use static-protection equipment when handling the module to prevent damage to sensitive electronic components.

Other ABB product models:

ABB 3BHE044249R0003

ABB 3BHE046836R0101

ABB 3BHE046836R0102 GFD563A102

ABB 3BHL000250P0002

ABB 3BHL000391P0101 5SHX1445H0001

ABB 3BHL000406P0009

ABB 3BHL000406P0103

ABB 3BHL000519P0001

ABB 3BHL000734P0003

ABB 3BHL000986P0006

ABB 3BHL001433P0001

ABB 3BHT300011R1

ABB 3BSE003816R1 SC520

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004172R1 PFTL101A-2KN

ABB 3BSE004172R1 PFTL101A 2KN

ABB 3BSE018135R1

ABB 3BSE019050R200 PFTL301E-0.2kN

ABB 3BSE030928R1 SM810K01

ABB 3BSE042235R2

ABB 3BSE042236R1 PP865

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE043660R1 CI867K01

ABB 3BSE056899R1 CI873K01

ABB 3BSE066490R1

ABB 3BSE076939R1 PM866AK01

ABB 3BSE091722R1 LD 810HSE EX

ABB 3BSE092689R1

ABB 3BSE092689R1 CI867AK01

ABB 3BSE092978R1 PP881

ABB 3BUS208797-001

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626